Sm2Co17 type sintered magnet with low temperature coefficient and preparation method thereof

A low temperature coefficient, sintered magnet technology, applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., can solve the problems of expensive, low intrinsic coercive force, reduced intrinsic coercive force, etc., to achieve cost Low, high magnetic properties, the effect of less heavy rare earth content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

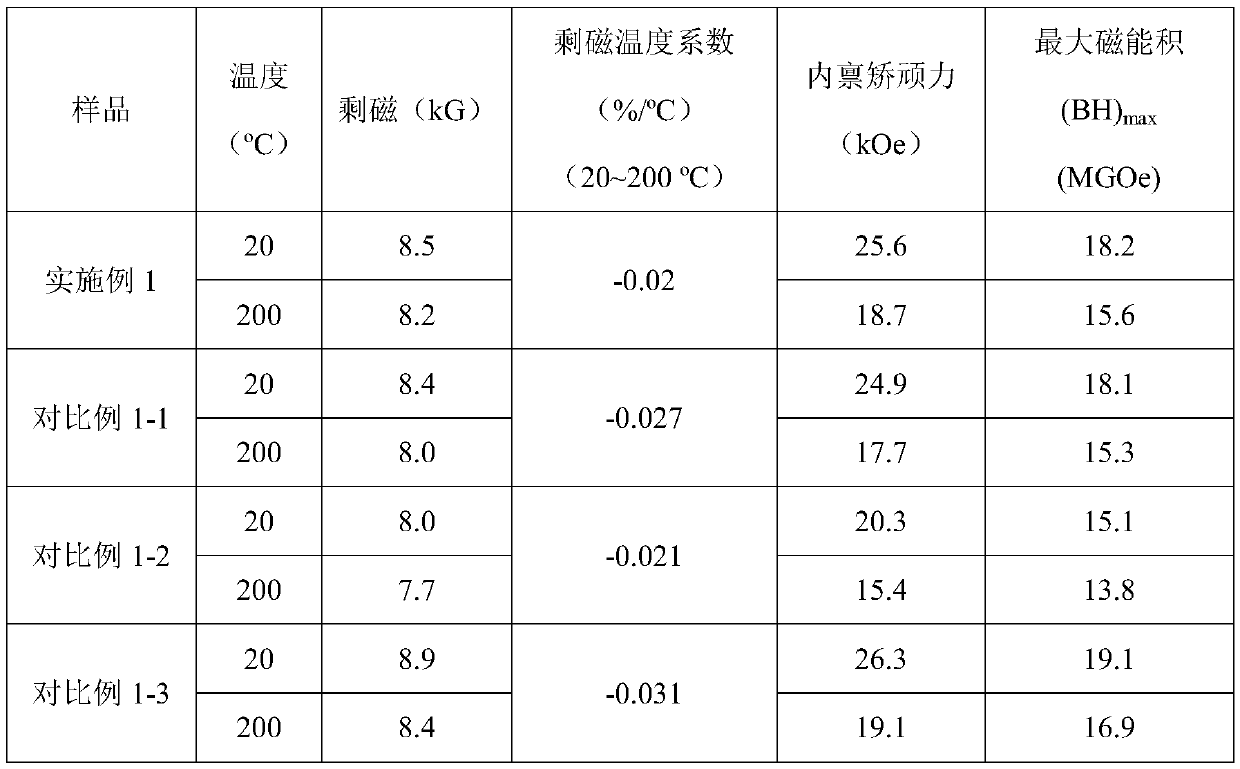

Embodiment 1

[0019] (1) Alloy Sm(CoFeCuZr) z , by mass percentage, Sm=15%, Co=77.5%, Fe=5%, Cu=2%, Zr=0.5%, weigh the raw materials according to the mass ratio of the above elements, mix the raw materials for vacuum induction melting, The power is 45kW, the vacuum degree is less than 5*10 -2 Pa, after the metal is melted, it is refined for 5-10 minutes to make an alloy ingot and coarsely crushed until the particle size of the powder is 300-500 μm.

[0020] (2) Alloy RECuZr (RE is Dy, Er) according to mass percentage, Dy=40%, Er=30%, Cu=20%, Zr=10%, weigh raw material according to the mass ratio of above-mentioned each element, raw material Mixing for vacuum induction melting, the power is 45kW, the vacuum degree is less than 5*10 -2 Pa, after the metal is melted, refining is carried out for 5-10 minutes to obtain an alloy ingot, and the DyErCuZr alloy powder is produced by high-energy ball milling, and the particle size of the powder is 50-200nm.

[0021] (3) Sm(CoFeCuZr) obtained in st...

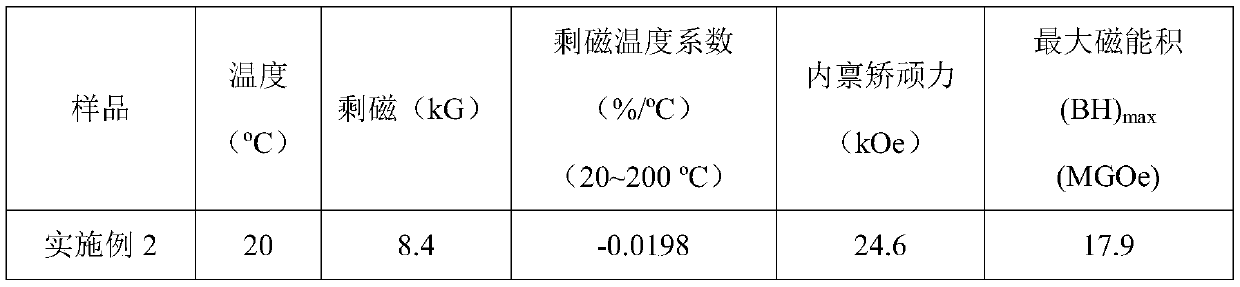

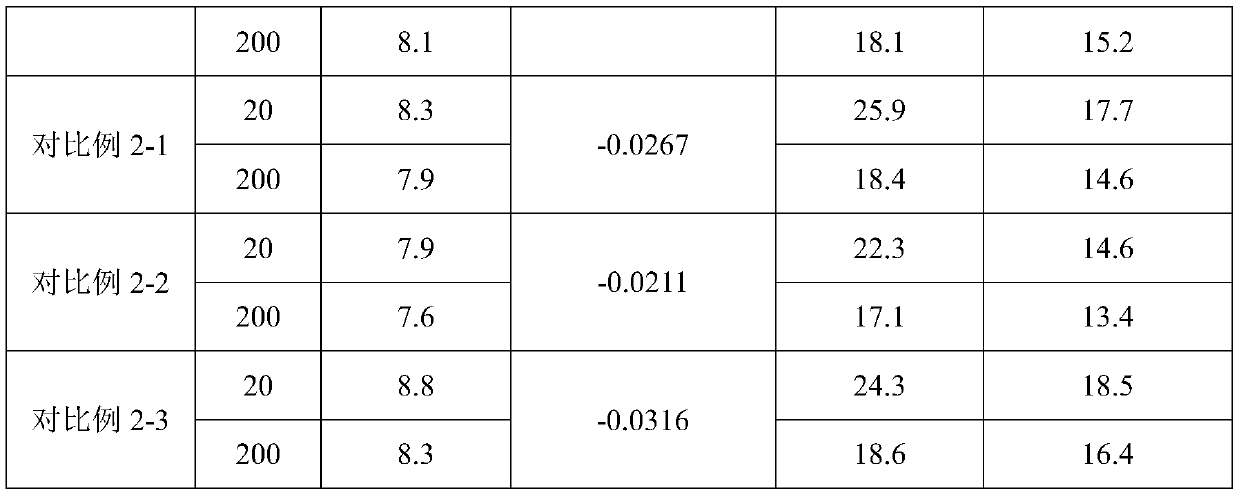

Embodiment 2

[0046] (1) Alloy Sm(CoFeCuZr) z , by mass percentage, Sm = 20%, Co = 72.5%, Fe = 5%, Cu = 2%, Zr = 0.5%, weigh the raw materials according to the mass ratio of the above elements, and then mix the raw materials for vacuum induction melting , power is 45kW, vacuum degree is less than 5*10 -2 Pa, after the metal is melted, it is refined for 5-10 minutes to make an alloy ingot, and then coarsely crushed until the particle size of the powder is 300-500 μm;

[0047] (2) Alloy RECuZr (RE is Dy, Gd) according to mass percentage, Dy=40%, Gd=30%, Cu=20%, Zr=10%, weigh raw material according to the mass ratio of above-mentioned each element, raw material Mixing for vacuum induction melting with a power of 45kW and a vacuum degree of less than 5*10 -2 Pa, after the metal is melted, refining is carried out for 5-10 minutes to obtain an alloy ingot, and the Dy GdCuZr alloy powder is produced by high-energy ball milling, and the particle size of the powder is 50-200nm.

[0048] (3) Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com