Ultralow residual magnetism temperature coefficient rare-earth permanent-magnet material and preparation method thereof

A rare earth permanent magnet, magnetic temperature technology, applied in magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc. The effect of low remanence temperature coefficient, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

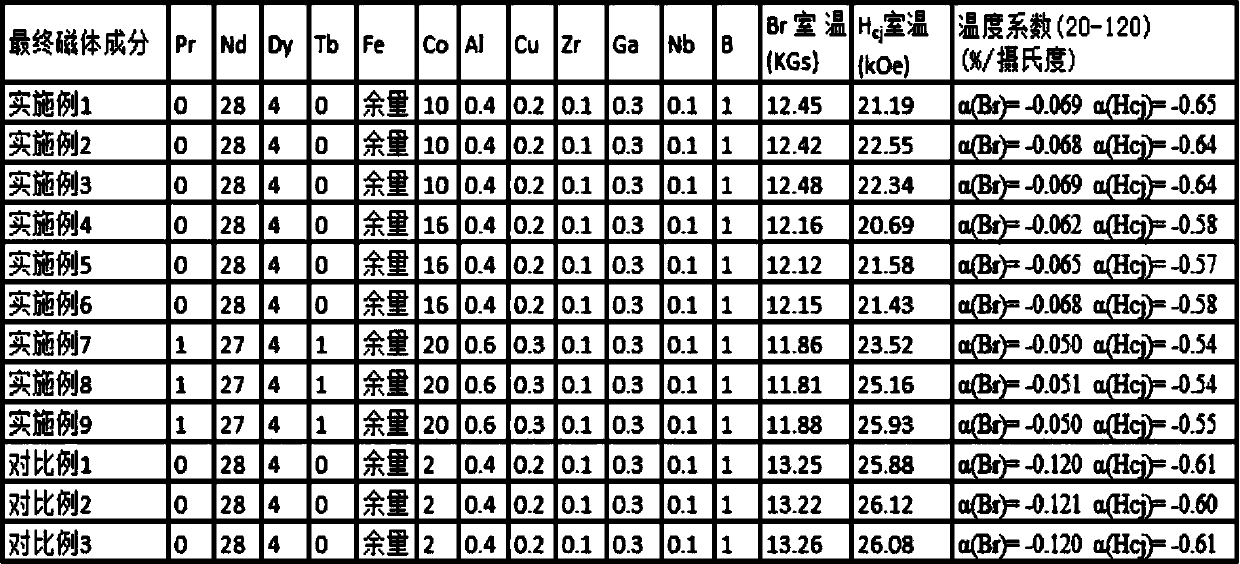

Examples

Embodiment 1

[0028] A preparation method of ultra-low remanence temperature coefficient rare earth permanent magnet material, the composition is Nd 28 Dy 4 Fe ball Co 10 Al 0.4 Cu 0.2 Ga 0.3 Nb 0.3 Zr 0.1 B 0.98 The neodymium iron boron permanent magnet material (where ball represents the margin, the same below) is prepared according to the technical scheme of the present invention: after the above-mentioned ingredients are mixed, smelt, shake the sheet, and then the obtained quick-setting sheet is broken by hydrogen , Jet mill crushed into powder with an average particle size of 5 microns. Orient and shape the above powder into a blank under a magnetic field of 2T, apply 300Mpa isostatic pressing to the blank, and then perform vacuum sintering at 1000°C for densification, and then perform primary and secondary tempering processes to finally obtain permanent magnet materials , The measured performance and temperature coefficient are shown in Table 1.

Embodiment 2

[0030] A preparation method of ultra-low remanence temperature coefficient rare earth permanent magnet material, the composition is Nd 28 Dy 2 Fe ball Co 10 Al 0.2 Cu 0.1 Ga 0.1 Nb 0.2 Zr 0.1 B 0.98 The neodymium iron boron permanent magnet material (where ball represents the margin, the same below) is prepared according to the technical scheme of the present invention: after the above-mentioned ingredients are mixed, smelt, shake the sheet, and then the obtained quick-setting sheet is broken by hydrogen , Jet mill crushed into an average particle size of 3 microns to obtain the main phase powder. The secondary alloy composition is Dy 20 Fe ball Cu 1 Al 2 , Smelt, shake the flakes, and crush to an average particle size of 1 micron by ball milling to obtain secondary phase powder. According to the composition range required by the present invention, the above-mentioned two powders are fully mixed in proportions, and at the same time, 0.1% mass fraction of antioxidant is added...

Embodiment 3

[0032] A preparation method of ultra-low remanence temperature coefficient rare earth permanent magnet material, the composition is Nd 28 Dy 2 Fe ball Co 10 Al 0.2 Cu 0.1 Ga 0.1 Nb 0.2 Zr 0.1 B 0.98 The neodymium iron boron permanent magnet material (where ball represents the margin, the same below) is prepared according to the technical scheme of the present invention: after the above-mentioned ingredients are mixed, smelt, shake the sheet, and then the obtained quick-setting sheet is broken by hydrogen Process crushing to obtain the main phase powder with an average particle size of 2 microns. The secondary phase alloy is Dy 20 Fe ball Cu 10 Al 20 The components are smelted, flakes are thrown, and the secondary phase powder with an average particle size of 2 microns is obtained through hydrogen breaking process. According to the composition range required by the present invention, the above two powders are fully mixed, and at the same time 0.5% of the mass fraction of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com