Method for producing samarium-cobalt series sintered materials

A sintered material, samarium cobalt technology, applied in the direction of magnetic materials, electrical components, circuits, etc., can solve the problems of high technical difficulty, decreased magnet performance, poor performance of samarium cobalt magnetic powder, etc., to achieve simple and convenient preparation process, optimize microstructure, Guaranteed magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

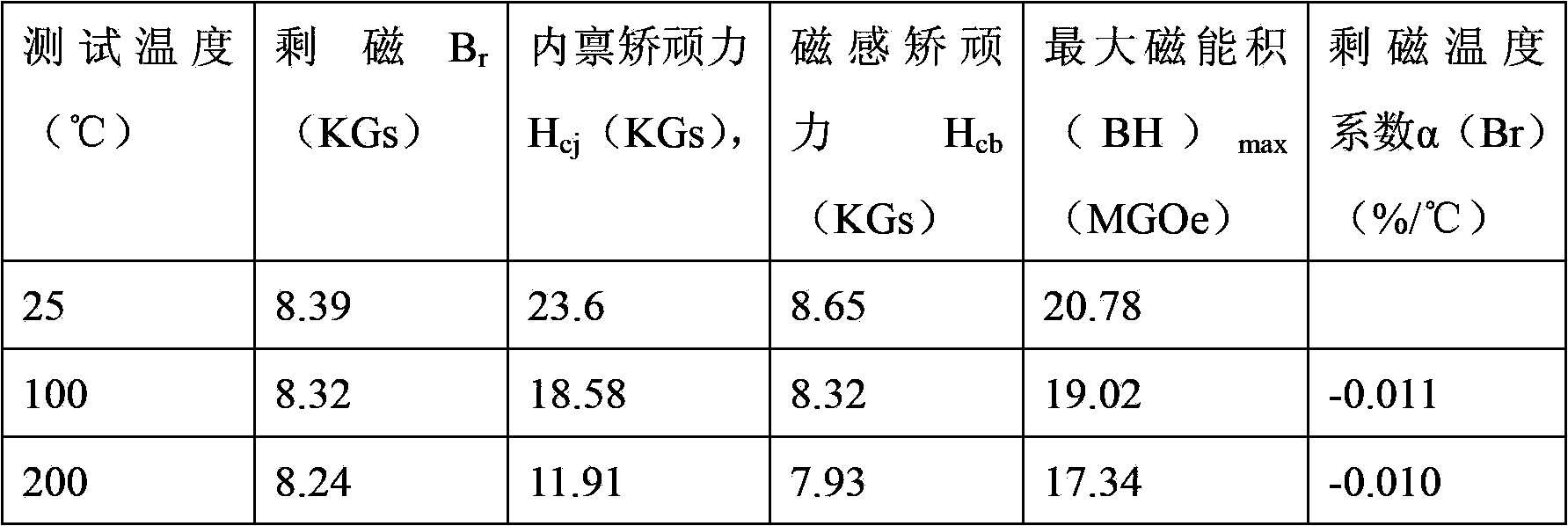

Embodiment 1

[0032] Raw materials were weighed according to the following weight fractions: samarium: 16.9%; cobalt: 49%; iron: 15.5%; copper: 6.3%; zirconium: 2.6%; dysprosium: 1.6%; 0.1%.

[0033] 1) Alloy smelting: Co and alloy elements are mixed according to the ratio, placed in a water-cooled copper crucible in an electric arc furnace, Sm and metal calcium are mixed in a feeder, and vacuumed to 10 -3 Pa or above, then pass high-purity argon gas at 0.1 atmospheric pressure, working voltage 30V, working current 630A, melt under the protection of argon, but all the materials in the crucible are melted, add the mixture of samarium and calcium, and repeatedly melt 4 times To obtain alloy liquid with uniform composition;

[0034] 2) Rapid quenching: casting the uniformly smelted alloy liquid onto a rotating water-cooled copper roll, water-cooled molybdenum roll, copper plate or molybdenum plate at a speed of 0.6m / s to prepare an alloy cast strip;

[0035] 3) Magnetic powder preparation: c...

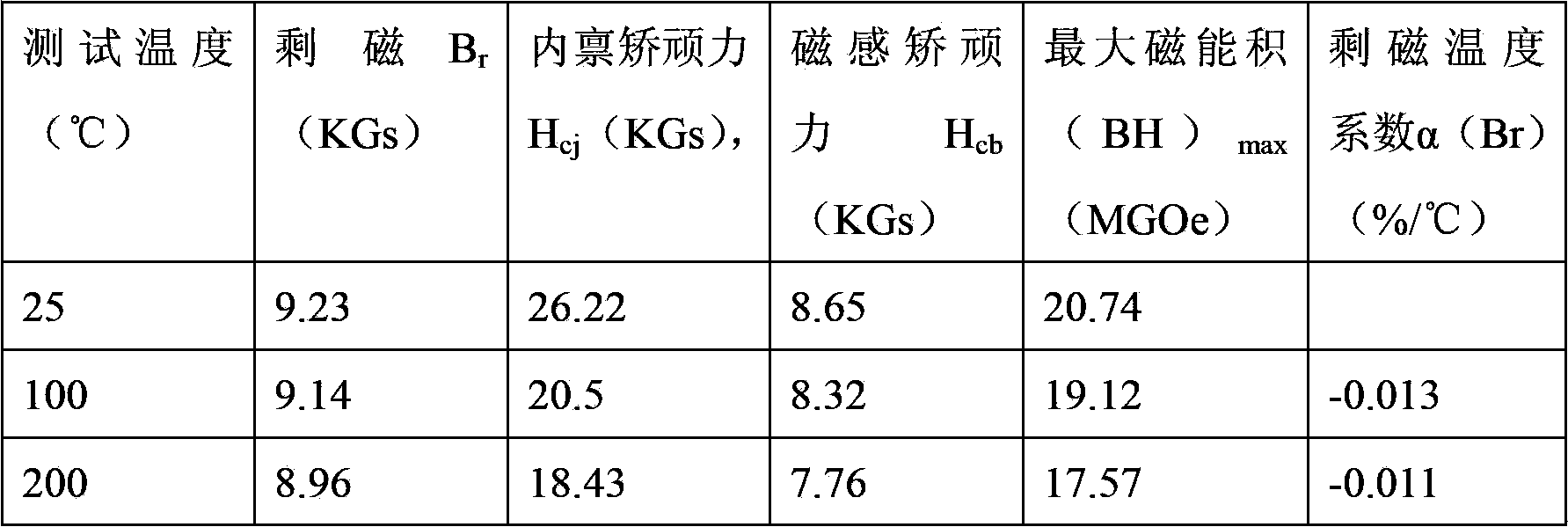

Embodiment 2

[0043] Raw materials were weighed according to the following weight fractions: samarium: 20.78%; cobalt: 51.81%; iron: 12.93%; copper: 6.34%; zirconium: 1.71%; dysprosium: 5.43%, magnesium: 1%.

[0044] 1) Alloy smelting: Co and alloy elements are mixed according to the ratio, placed in a water-cooled copper crucible in an electric arc furnace, Sm and metal magnesium are mixed in a feeder, and vacuumed to 10 -3 Pa, then feed high-purity argon gas at 1.2 atmospheric pressure, working voltage 45V, working current 750A, smelting under the protection of argon, but all the materials in the crucible are melted, add the mixture of samarium and magnesium, and repeatedly smelt 3 times to get Alloy liquid with uniform composition;

[0045] 2) Rapid quenching: casting the uniformly smelted alloy liquid onto a rotating water-cooled copper roll, water-cooled molybdenum roll, copper plate or molybdenum plate at a speed of 0.6m / s to prepare an alloy cast strip;

[0046] 3) Magnetic powder p...

Embodiment 3

[0054] Weigh raw materials according to the following weight fractions: samarium: 16.9%; cobalt: 49%; iron: 15.5%; copper: 6.3%; zirconium: 2.6%; dysprosium: 1.6%; : 0.05% (the dosage of calcium hydride is calculated based on the calcium content).

[0055] 1) Alloy smelting: Mix Co and alloy elements according to the ratio, place in a water-cooled copper crucible in an electric arc furnace, place a mixture of Sm and calcium hydride in a feeder, and evacuate to 10 -3 Pa, then feed high-purity argon gas at 1.0 atmospheric pressure, working voltage 45V, working current 650A, melt under the protection of argon, but all the materials in the crucible are melted, add the mixture of samarium and calcium hydride, and repeatedly smelt for more than 4 times Obtain alloy liquid with uniform composition;

[0056] 2) Rapid quenching: casting the uniformly smelted alloy liquid onto a rotating water-cooled copper roll, water-cooled molybdenum roll, copper disc or molybdenum disc at a speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com