Method for preparing high-thermal-stability magnet through modification of zirconium-rich solvent on surface of magnetic powder

A high thermal stability, zirconium-rich technology, applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of large temperature coefficient, irreversible demagnetization, heavy motor, etc., and achieve low temperature coefficient of coercive force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

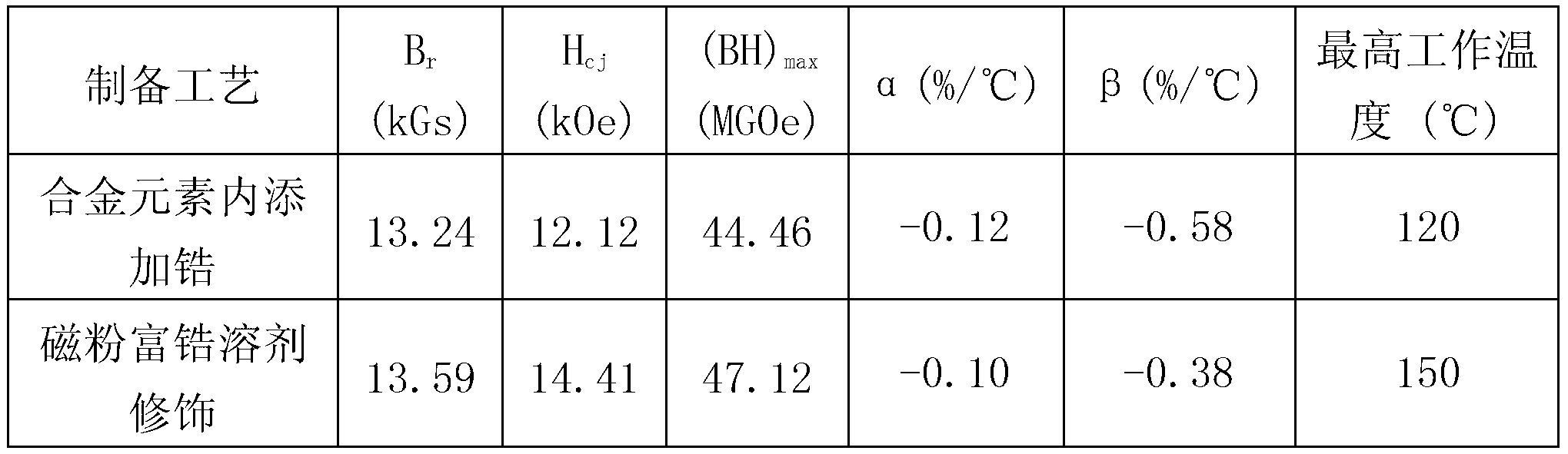

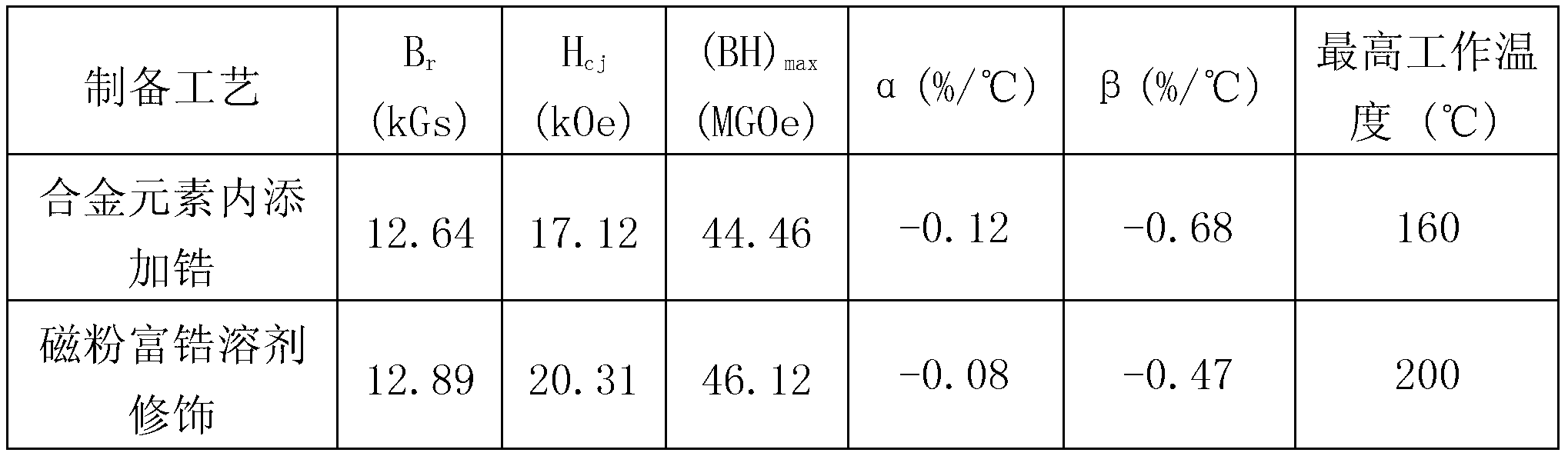

Embodiment 1

[0026] 1) The main phase alloy adopts the quick-setting sheet technology, the surface line speed of the copper roller is 1.2m / s, and the composition is Nd 13.12 Fe 80.69 B 5.73 (Dy 0.22 al 0.24 )(at%).

[0027] 2) Powder the main phase alloy. The primary crushing is carried out by a jaw crusher, the secondary crushing is carried out by a secondary crusher, and then the powder with an average particle diameter of 3.4 μm is made by jet milling under the protection of nitrogen.

[0028] 3) Uniformly mix the zirconium n-propoxide solvent with the main phase alloy powder, antioxidant, and gasoline in a mixer to form a mixed powder, wherein the weight of the zirconium n-propoxide solvent accounts for 3% of the total weight, and the antioxidant polyethylene oxide Alkyl ether accounts for 1% of the total weight, and gasoline accounts for 1% of the total weight.

[0029] 4) The mixed powder is pressed into a parison by a magnetic field orientation forming press, and the forming o...

Embodiment 2

[0036] 1) The main phase alloy adopts the quick-setting sheet technology, the surface line speed of the copper roller is 2.0m / s, and the composition is Nd 14.2 Fe 78.23 B 5.81 (Tb 0.33 al 0.24 co1 Nb 0.18 )(at%).

[0037] 2) Powder the main phase alloy. The coarse crushing is carried out by a jaw crusher, the secondary crushing is carried out by a secondary crusher, and then the powder with an average particle diameter of 3.3 μm is made by jet milling under the protection of nitrogen.

[0038] 3) Uniformly mix zirconium n-butoxide solvent with main phase alloy powder, antioxidant and gasoline in a mixer to form a mixed powder, in which the weight of zirconium n-butoxide solvent accounts for 8% of the total weight, and the antioxidant polyethylene oxide Mono fatty acid ester accounts for 4% of total weight, gasoline accounts for 1% of total weight.

[0039] 4) The mixed powder is pressed into a parison by a magnetic field orientation forming press, and the forming orient...

Embodiment 3

[0046] 1) The main phase alloy is made of NdFeB ingot alloy by casting process, and the composition is Nd 11.06 Fe 82.4 B 5.85 Dy 0.89 (at%).

[0047] 2) Powder the main phase alloy. The coarse crushing is carried out by a jaw crusher, the secondary crushing is carried out by a secondary crusher, and then the powder with an average particle diameter of 4.3 μm is made by jet milling under the protection of nitrogen.

[0048] 3) Uniformly mix the zirconium tetra-tert-butoxide solvent with the main phase alloy powder, antioxidant, and gasoline in a mixer to form a mixed powder, in which the weight of the zirconium tetra-tert-butoxide solvent accounts for 2% of the total weight, and the antioxidant polyepoxide Ethane mono fatty acid ester accounts for 4% of the total weight, and gasoline accounts for 2% of the total weight.

[0049] 4) The mixed powder is pressed into a parison by a magnetic field orientation forming press, and the forming orientation magnetic field is 1.6T, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com