Liquid cooling case based on 3U-VPX and method

A 3U-VPX, liquid cooler technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of power output power limitation, limited heat dissipation capacity, etc., to improve heat dissipation capacity, The effect of small size and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

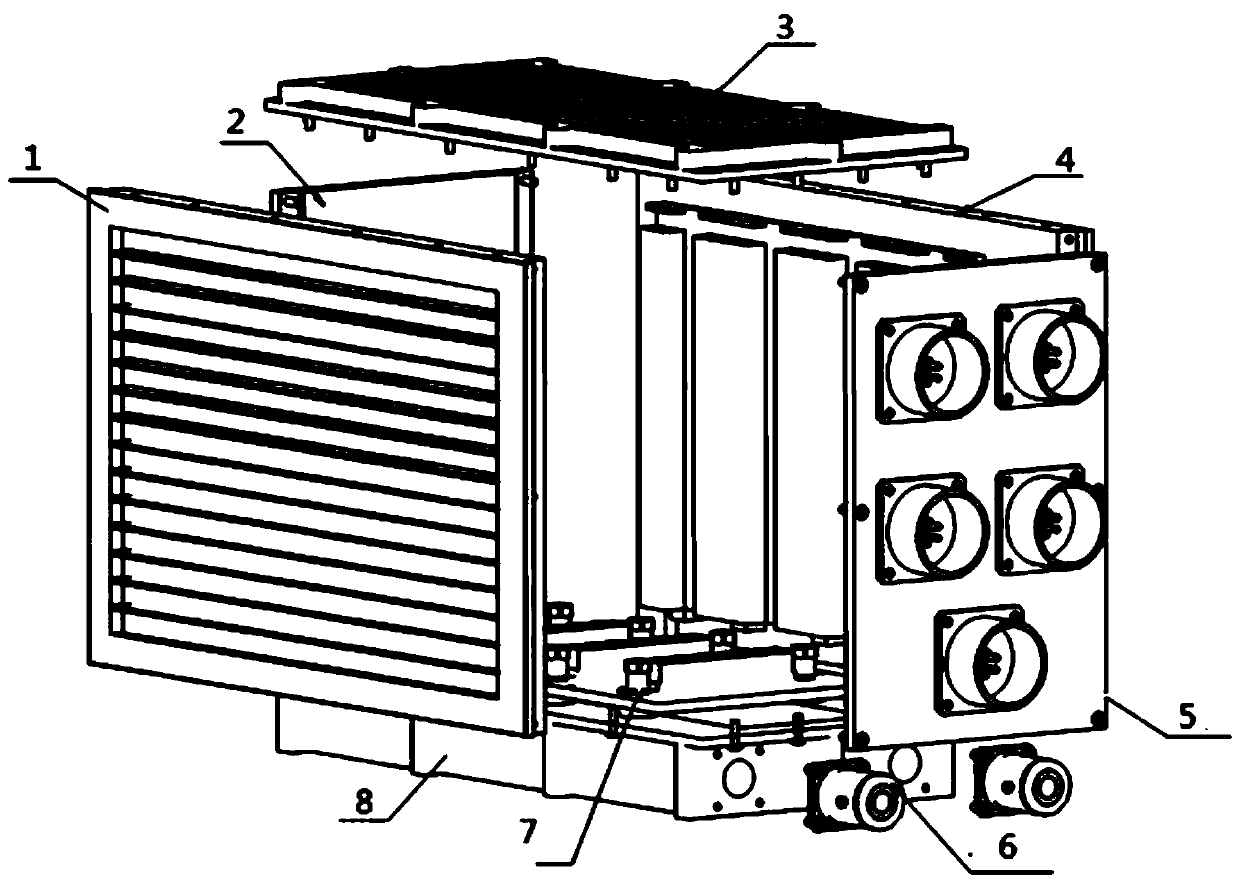

[0021] Such as figure 1 As shown, a 3U-VPX liquid-cooled chassis includes: cover plate 3, left side plate 1, right side plate 4, front panel 5, rear panel 2, bottom plate 8, TSA external fluid connector 6, TSF internal branch fluid connector 7;

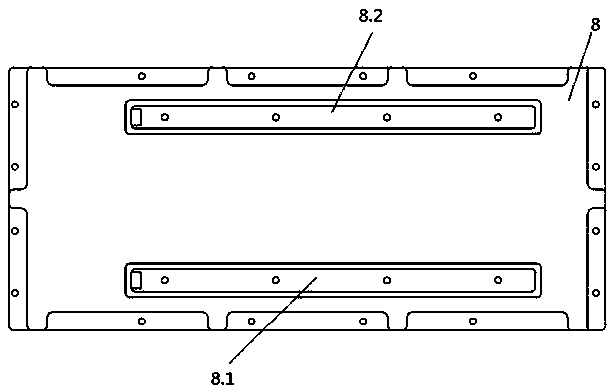

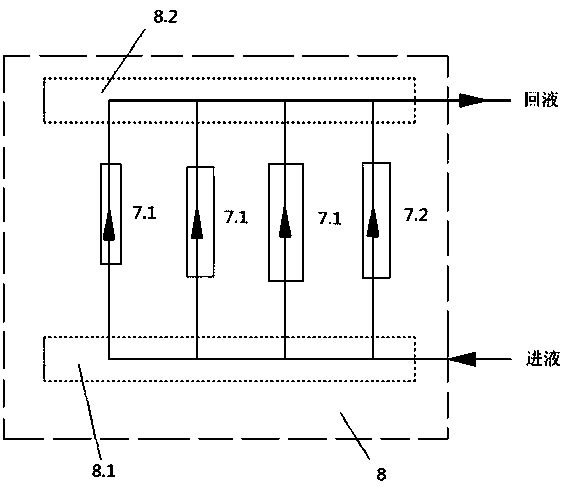

[0022] The bottom plate 8 has a rectangular structure, and the near two sides of the bottom plate 8 of the rectangular structure are respectively provided with a heat exchange flow channel 8.1 and a heat exchange flow channel 8.2; the heat exchange flow channel 8.1 is parallel to the heat exchange flow channel 8.2. The heat exchange flow channel 8.1 and the heat exchange flow channel 8.2 are connected through a plurality of TSF internal fluid connectors 7 to form a liquid-cooled heat exchange confluence channel of the liquid-cooled chassis; one end of the heat exchange flow channel 8.1 on the bottom plate is connected to the The TSA external fluid connector 6 is connected to form the liquid-cooled inlet of the liquid-cooled chassis; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com