Laser welding device and laser welding method

A laser welding and laser technology, applied in laser welding equipment, using optical devices, measuring devices, etc., can solve problems such as deviation of measured values, inability to measure with high precision, and achieve the effect of suppressing storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

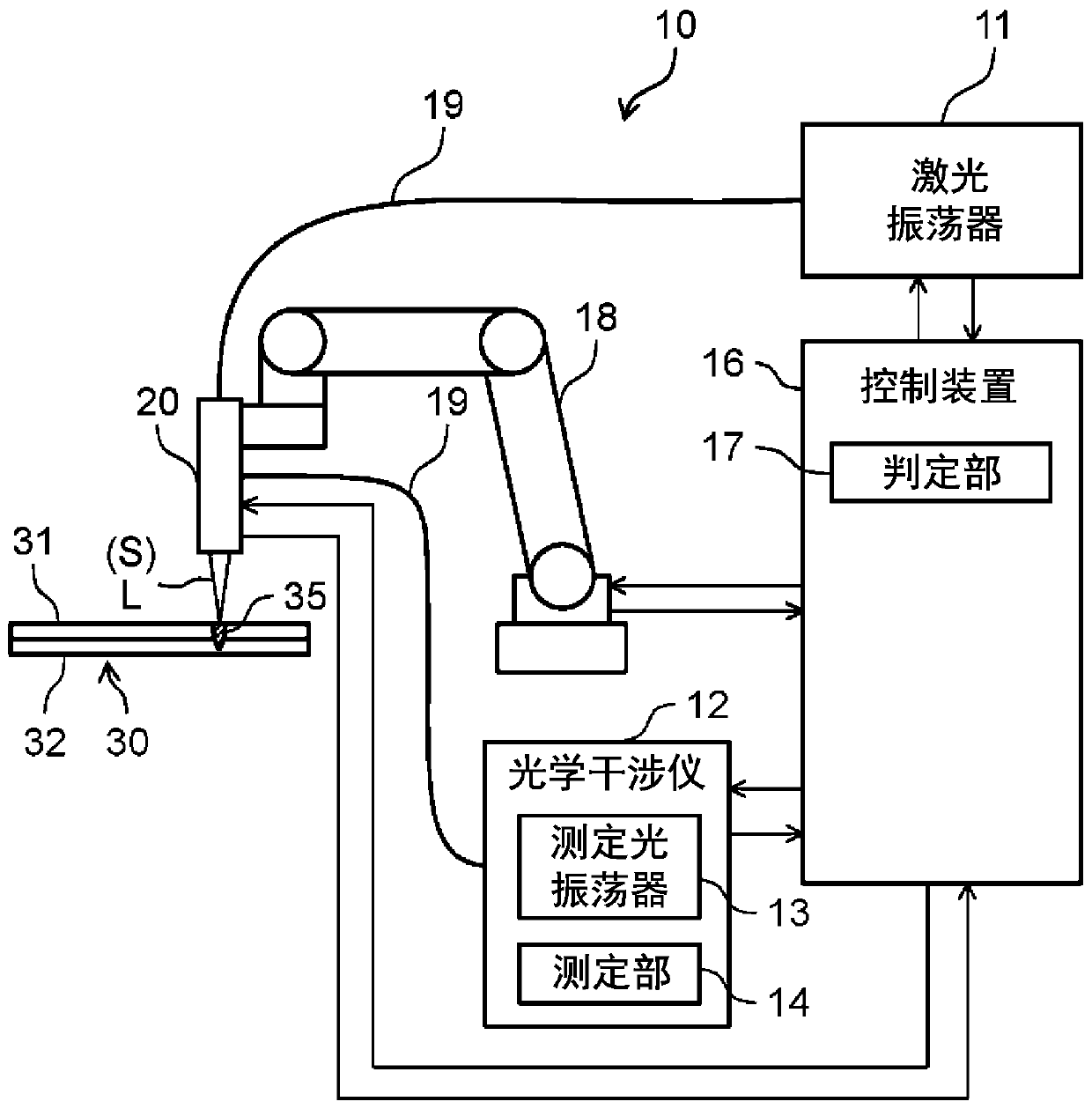

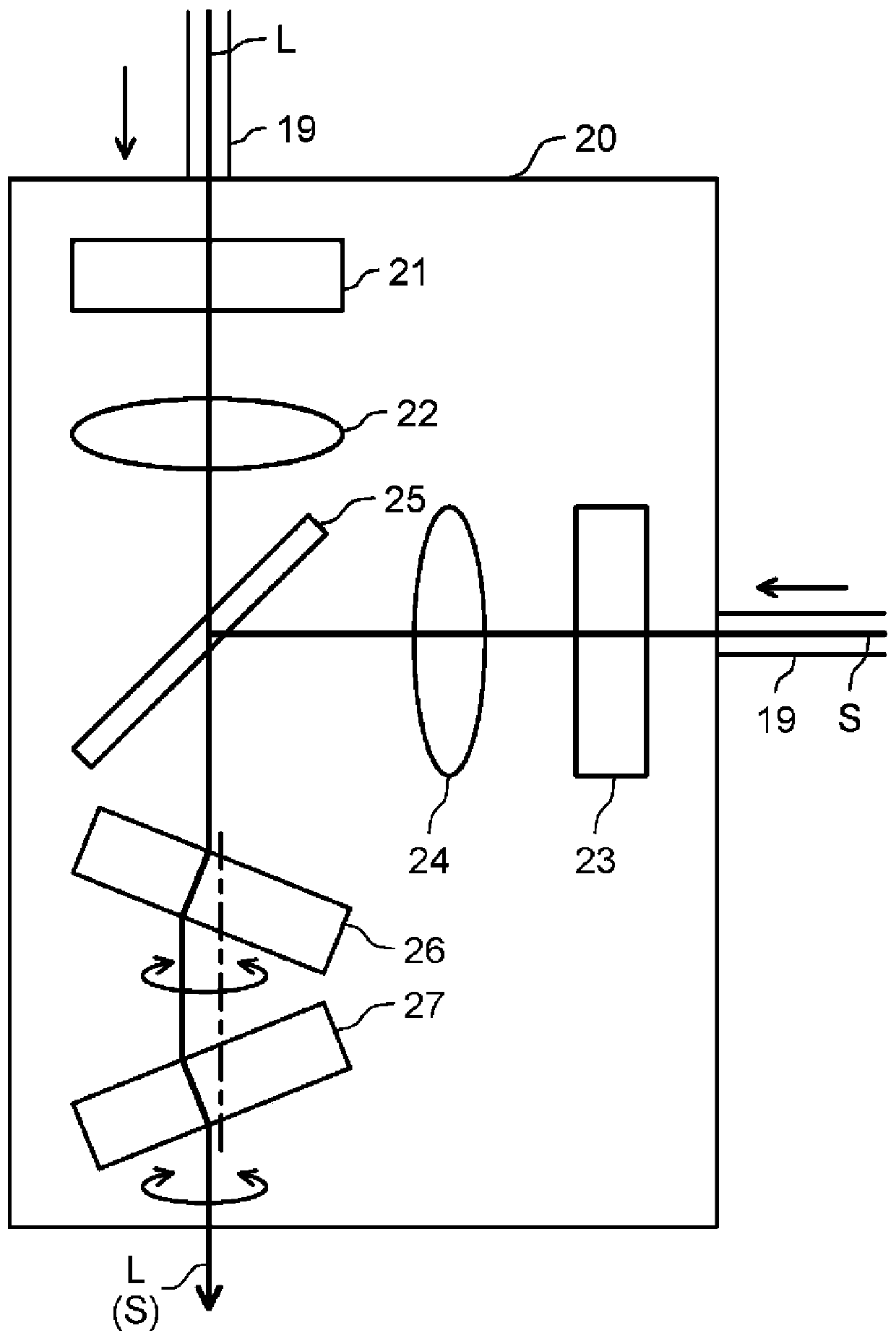

Method used

Image

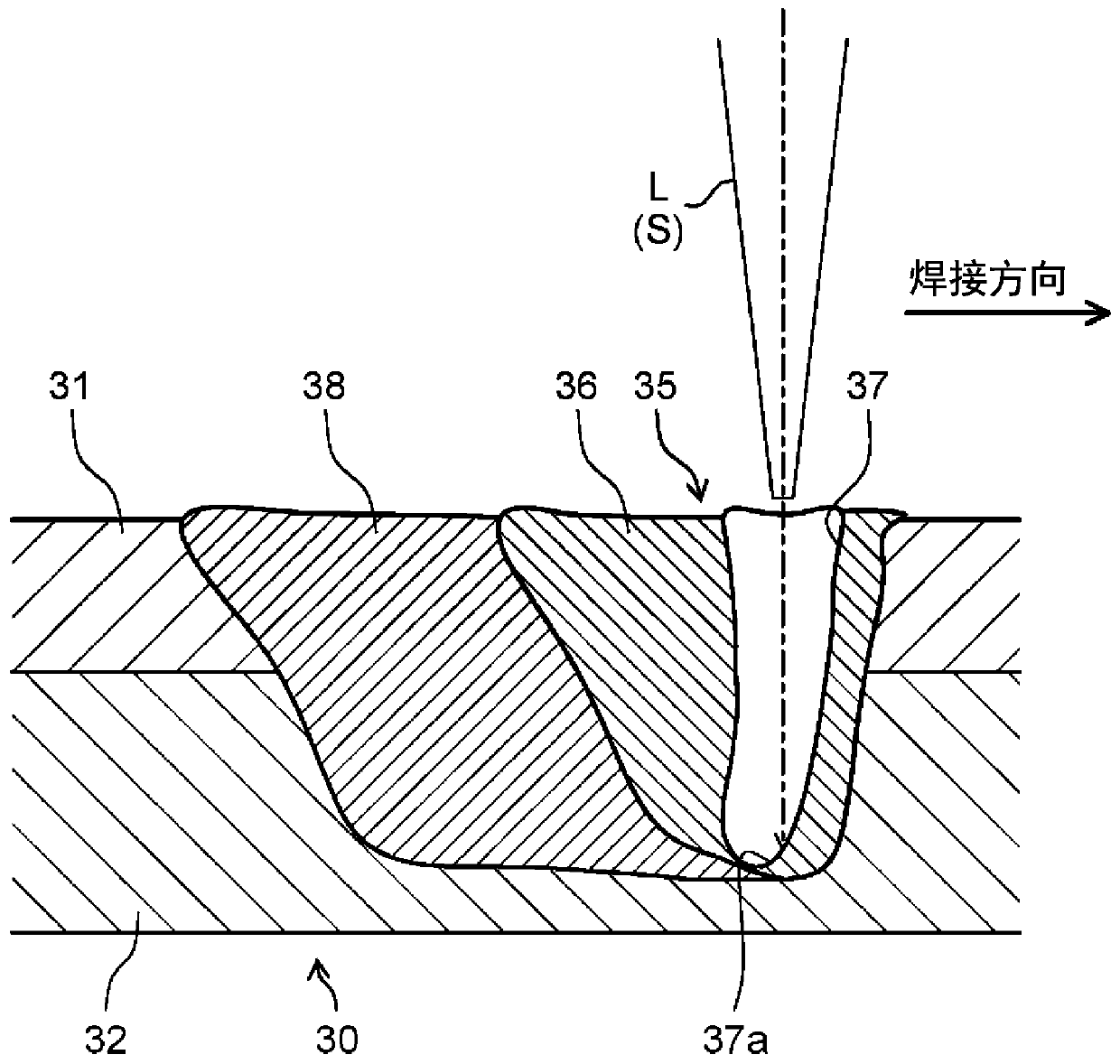

Examples

other Embodiment approach

[0137] Regarding the above-mentioned embodiment, the following configurations may also be adopted.

[0138] In this embodiment, the trajectory of the spin-orbit 40 may be not only a simple spiral shape, but also a polygonal shape such as a circle or a quadrangle. Additionally, if Figure 10 As shown, the elliptical trajectory may be formed discontinuously. That is, as long as it is a continuous trajectory capable of irradiating the measuring light S inside the small hole 37 , various shapes can be adopted. In addition, the rotation direction of the irradiation of the spin track 40 with respect to the welding direction of the laser light L may be clockwise or counterclockwise.

[0139] In addition, in the present embodiment, the laser light L and the measurement light S are moved and irradiated in a spiral shape along the linear welding path 34 , but the welding path is not limited to the linear shape. For example, consider a case where the laser irradiation head 20 is moved...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap