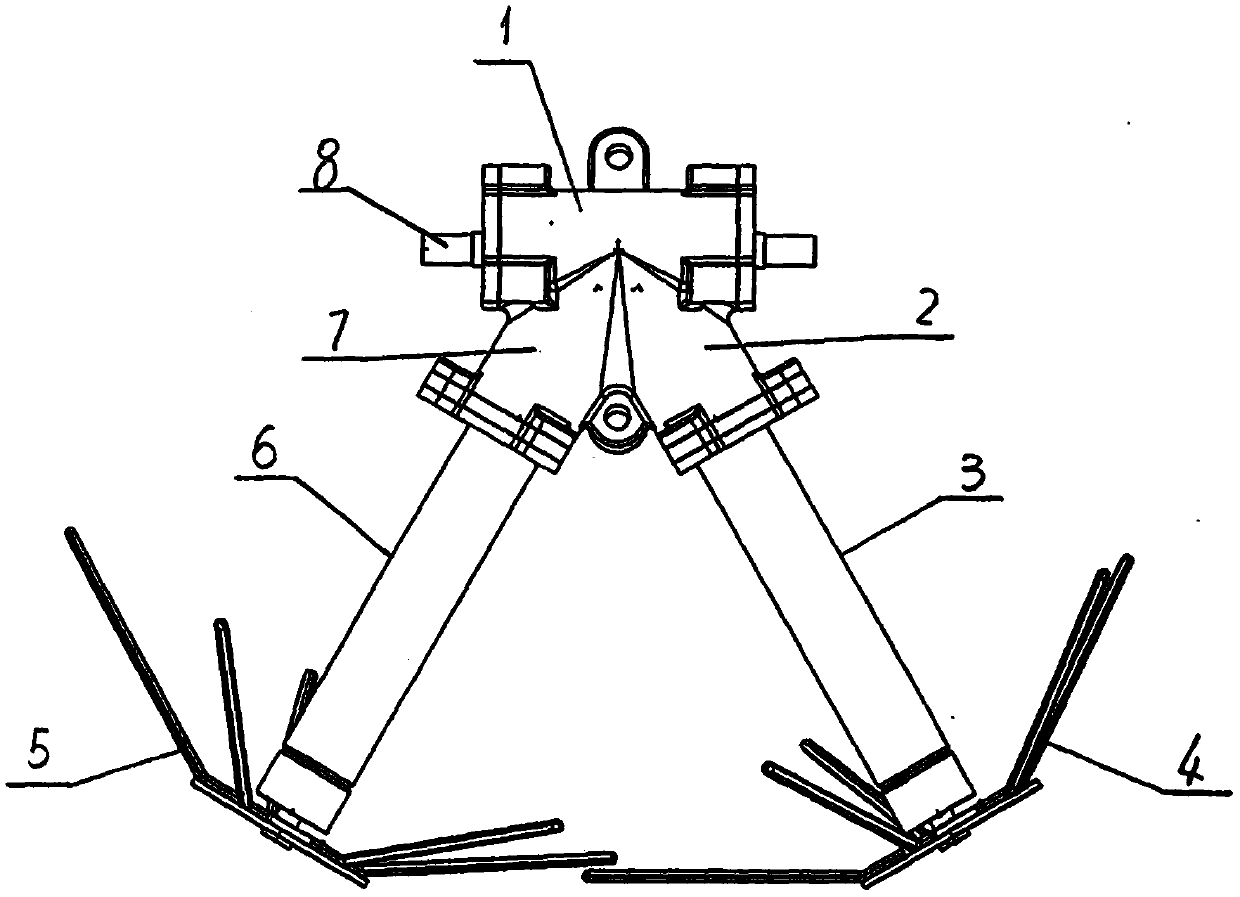

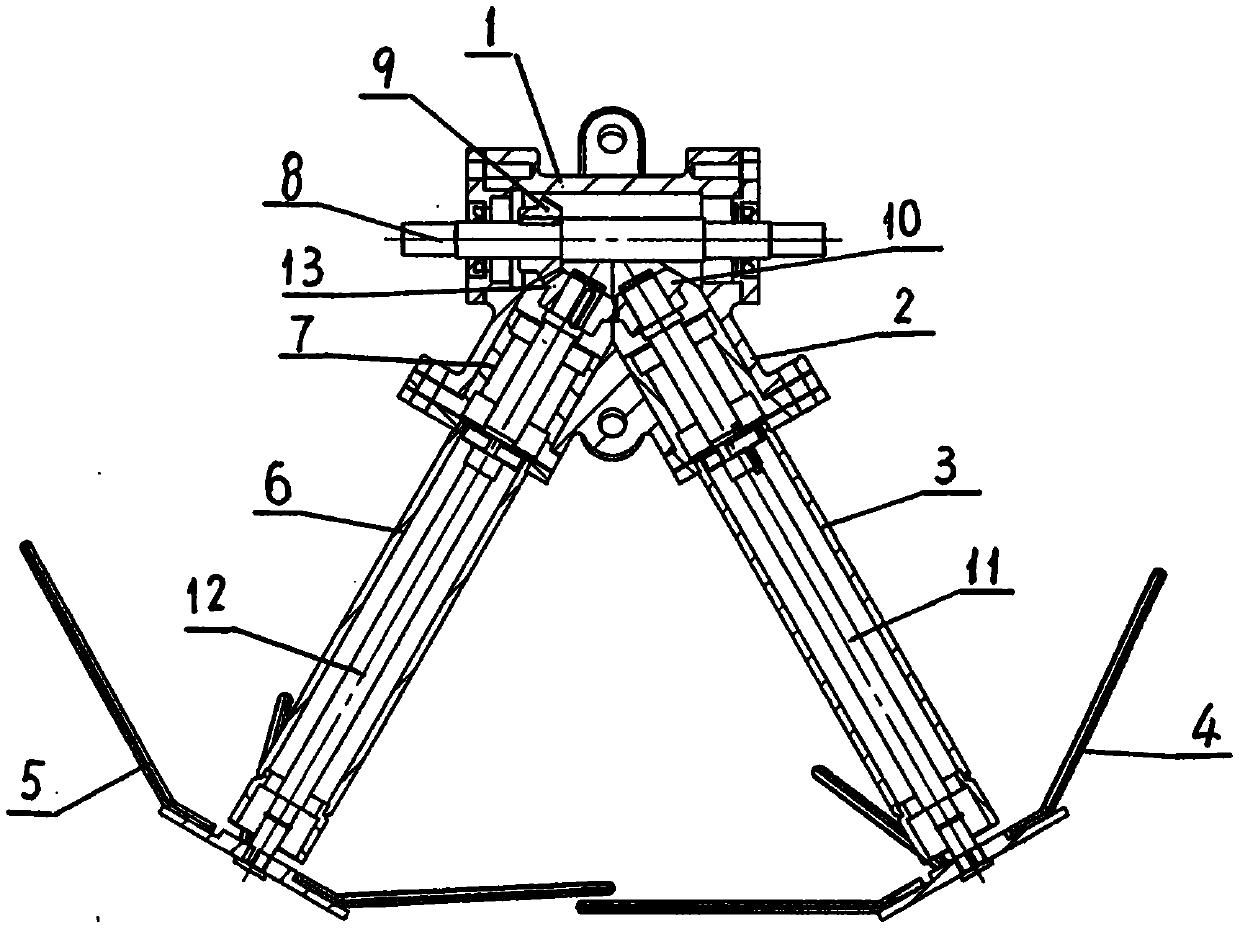

Inverted-V-shaped opposite type rice inter-seedling weeding assembly

A rice seedling and opposing technology, which is applied to cutters, agricultural machinery and implements, applications, etc., can solve the problems of affecting the growth and yield of rice, high manufacturing cost, low weeding efficiency, etc., so as to improve the quality and effect of weeding operations. Good, low rate of damage to seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An inverted V-shaped opposed weeding assembly between rice seedlings, a power input shaft 8 is rotatably installed on the mounting base 1, and the driving bevel gear 9 is fixed on the power input shaft 8; on the lower side of the mounting base 1 Install the left bearing seat 7 and the right bearing seat 2 in an inverted V-shaped symmetrical arrangement on the top, and install the left sleeve 6 and the right The sleeve 3, the left shaft 12 and the right shaft 11 are respectively rotatably mated and installed in the left bearing seat 7, the left sleeve 6, the right bearing seat 2, and the right sleeve 3. In the left shaft 12 and the right shaft 11 A left bevel gear 13 and a right bevel gear 10 are respectively fixed on the upper end, and the left bevel gear 13 meshes with the driving bevel gear 9 and the right bevel gear 10 respectively; on the lower ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com