Embedded oven

An embedded and oven technology, applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve problems such as scalding users, box rust, temperature rise, etc., to prolong service life, avoid hot hands, and ensure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

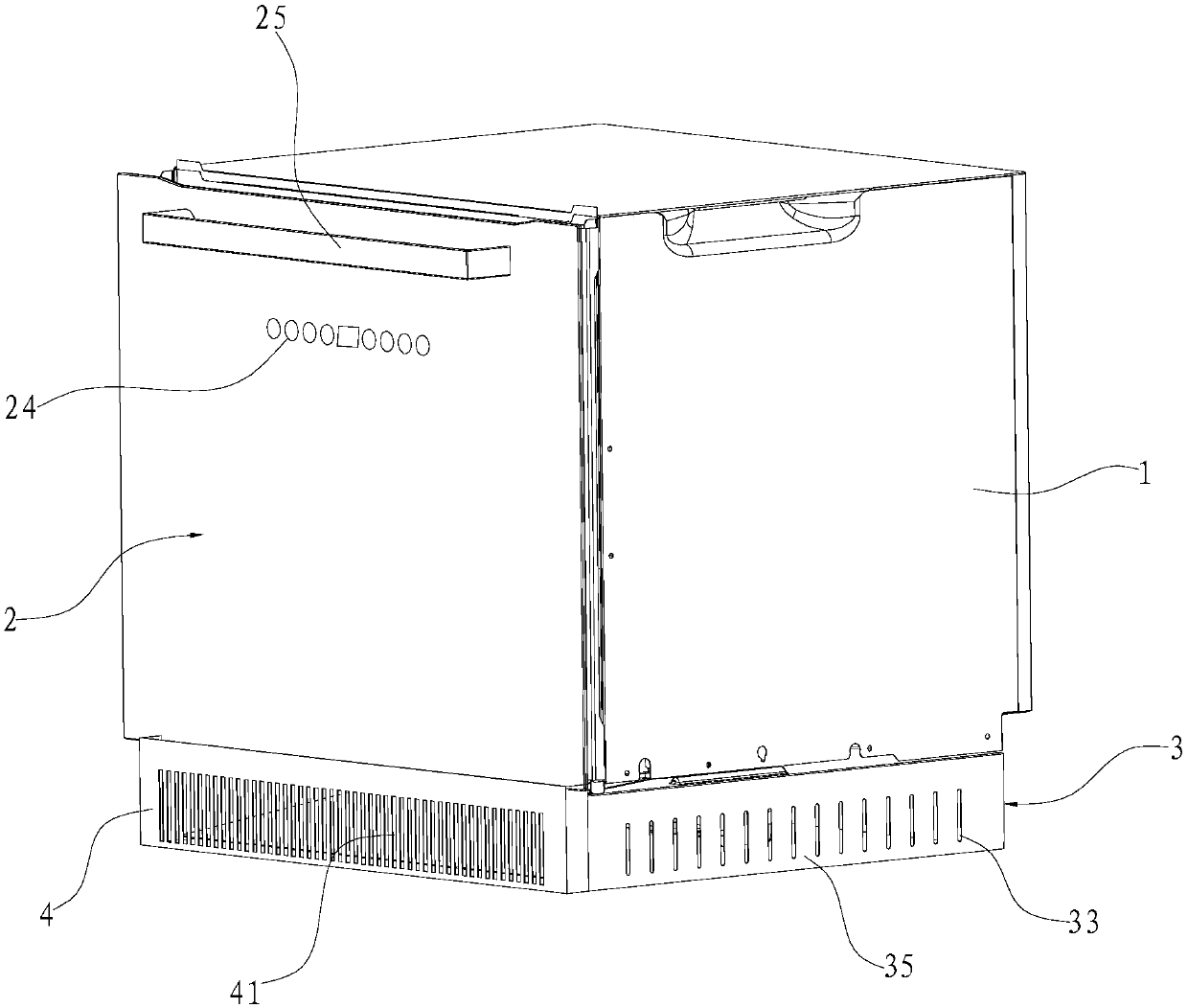

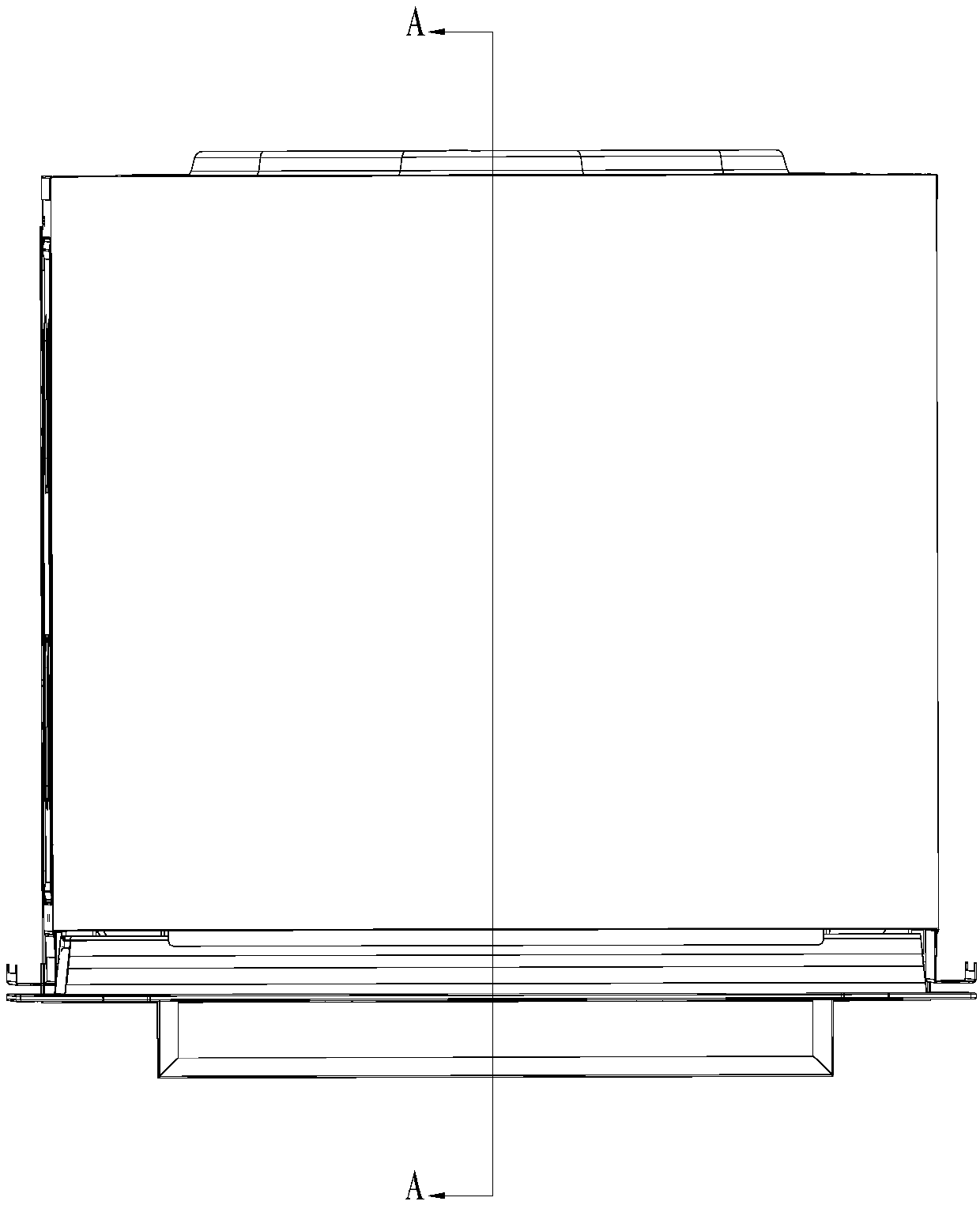

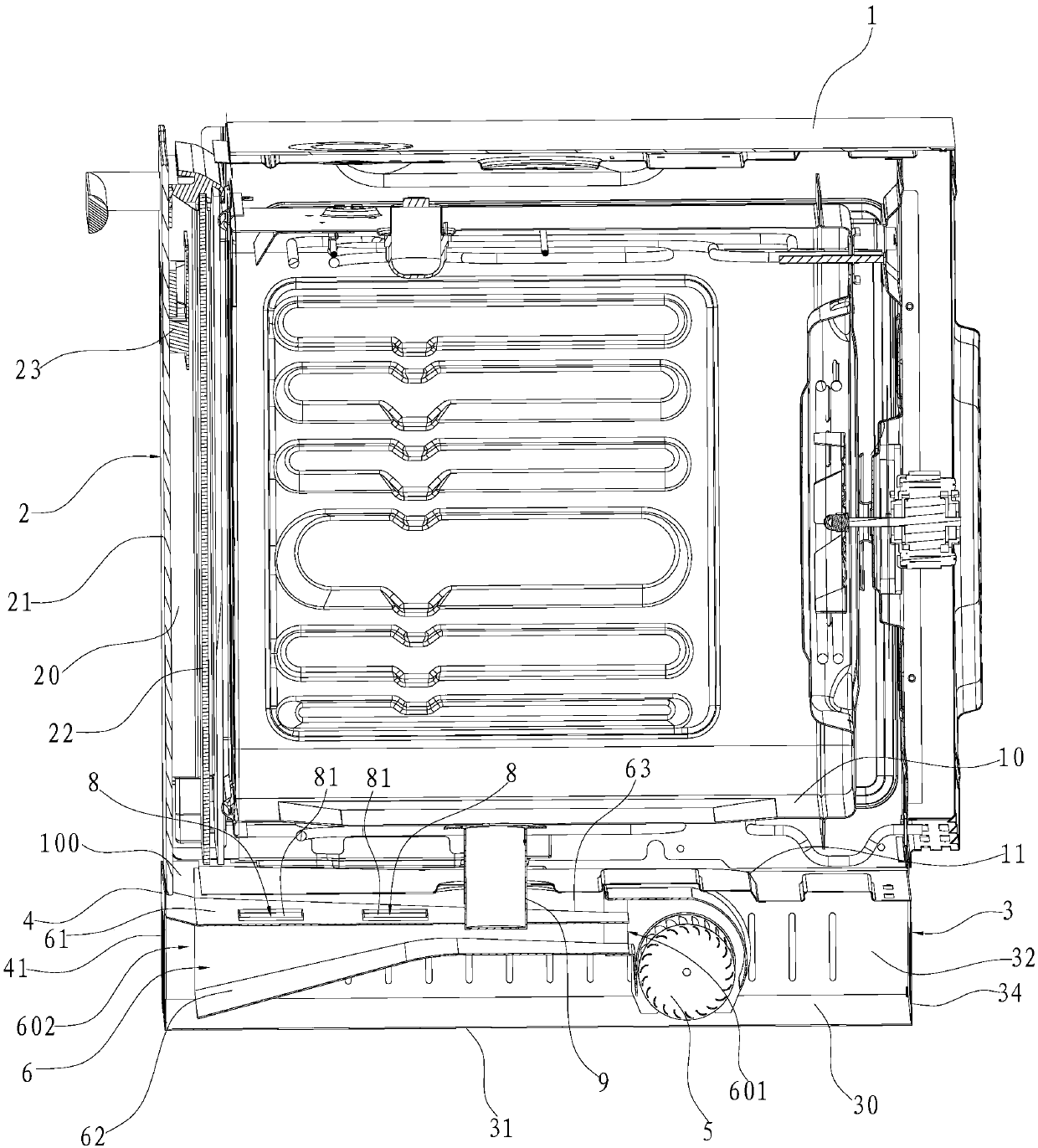

[0031] Such as Figure 1~6 As shown, a built-in oven includes a door body 2 and a box body 1, and the box body 1 is provided with an inner container 10 and a ventilation pipe 9, and the above-mentioned door body 2 includes an outer glass 21 and a door behind the outer glass 21. The middle glass 22 has a ventilation gap 20 between the outer glass 21 and the middle glass 22 . The bottom of the bottom plate 11 of the above-mentioned box body 1 is provided with a base 3 that matches it. The base 3 includes a lower base plate 31, a left side plate 32, a right side plate 33 and a back side plate 34. The lower base plate 31 is parallel to the above-mentioned base plate 11 and Located below the bottom plate 11, the above-mentioned left side plate 32, right side plate 33 and back side plate 34 are enclosed between the bottom plate 11 and the lower bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com