Graded crushing device for corn processing

A pulverizing device and corn processing technology, applied in grain processing and other directions, can solve the problems of low pulverizing efficiency and need to improve pulverizing effect, and achieve the effect of improving pulverizing efficiency, improving grinding effect and improving pulverizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

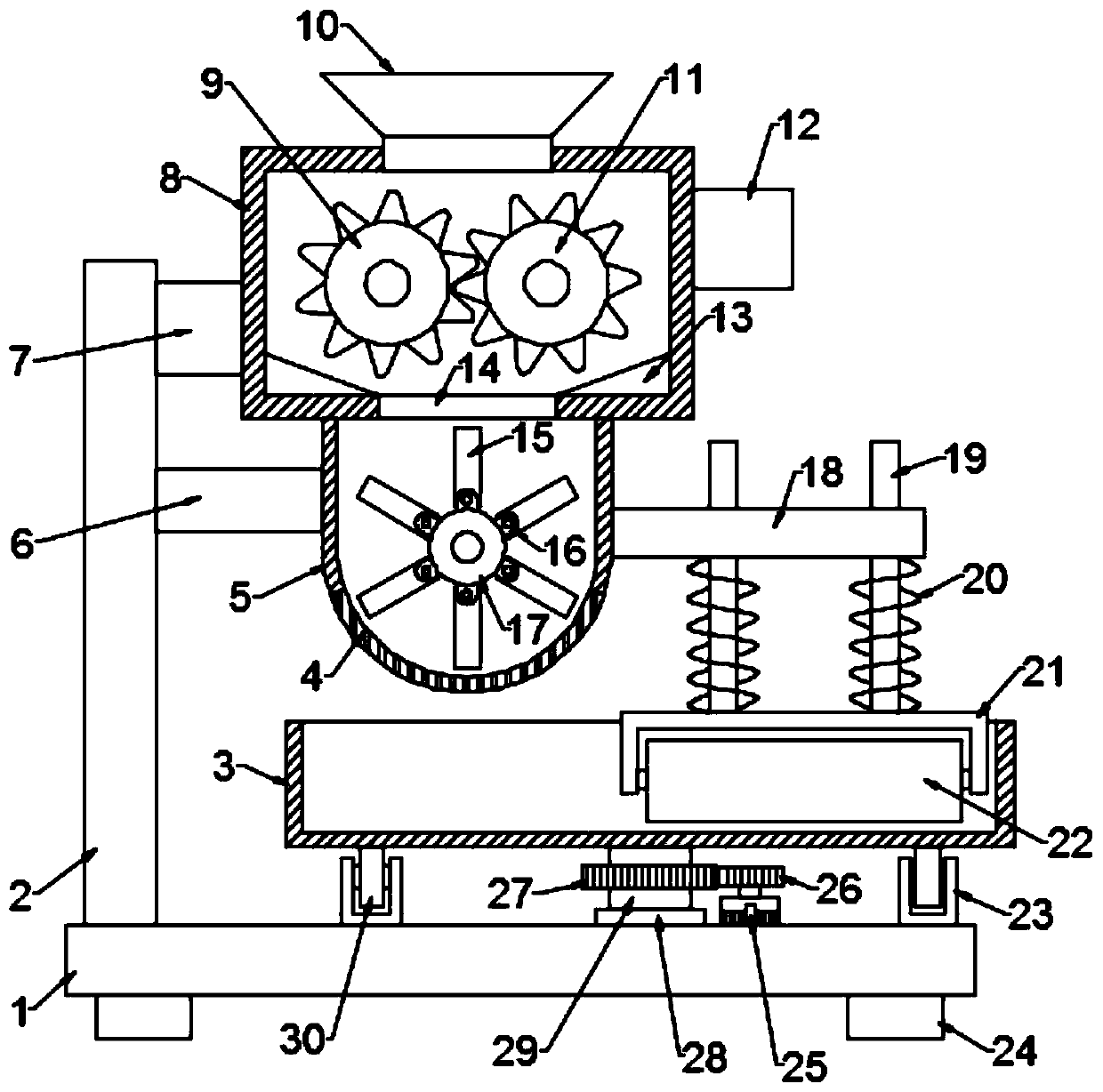

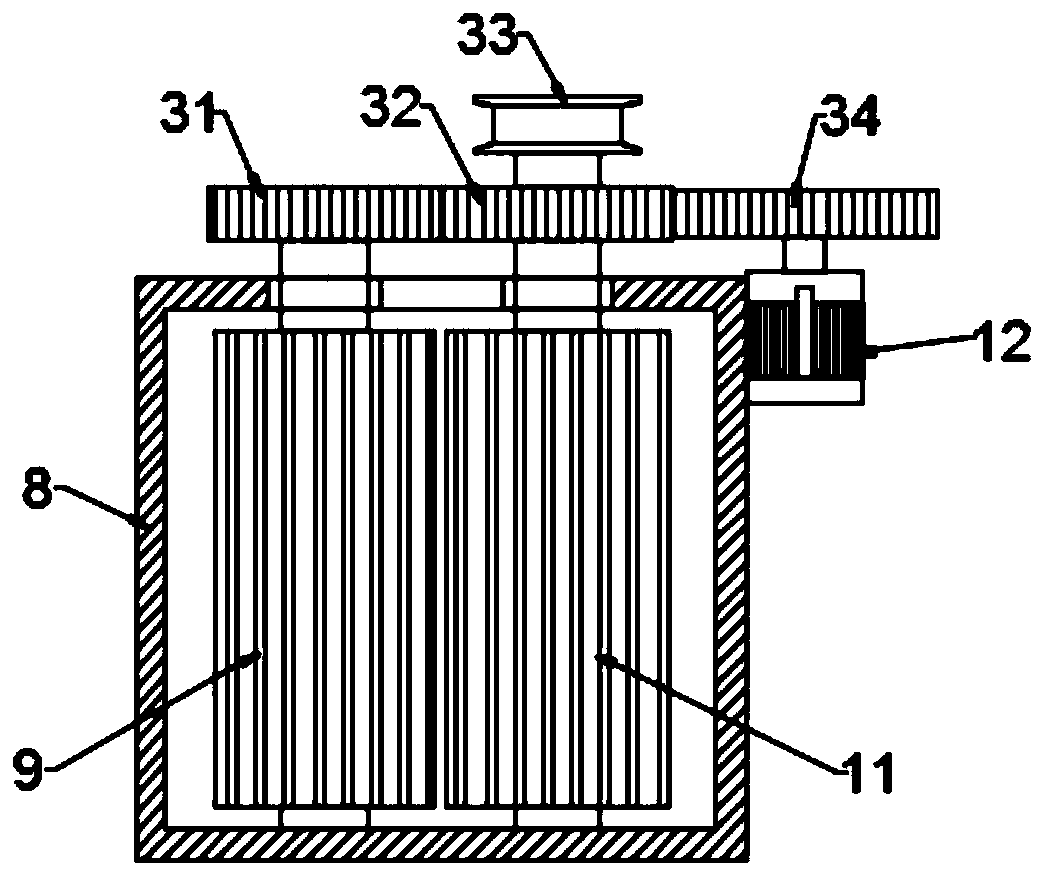

[0031] see Figure 1-3 , in the embodiment of the present invention, a kind of corn processing is used graded crushing device, comprises base plate 1, and the bottom of base plate 1 is provided with leg 24; There is a lower crushing box 5, and a column 2 is fixed on the bottom plate 1. The column 2 is provided with a first bracket 6 and a second bracket 7 for fixing the lower crushing box 5 and the upper crushing box 8 respectively, and the top wall of the upper crushing box 8 A feeding hopper 10 is installed on the top, a discharge port 14 is opened on the bottom wall of the upper crushing box 8, a discharge hole 4 is opened on the bottom wall of the lower crushing box 5, and a matching first crushing machine is arranged in the upper crushing box 8. The roller 9 and the second crushing roller 11, the first crushing roller 9 and the second crushing roller 11 are connected with the rotating shaft connected with the side wall bearing of the upper crushing box 8;

[0032] The up...

Embodiment 2

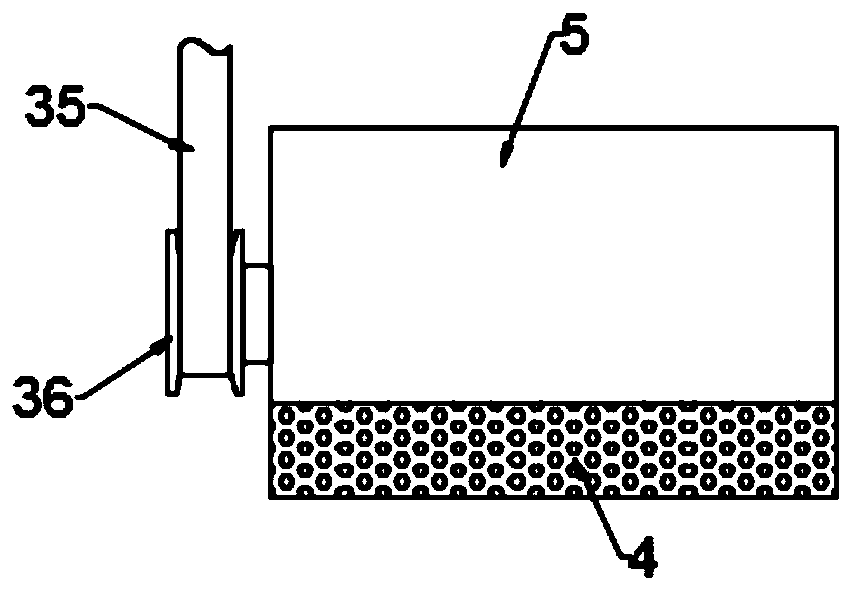

[0045] see Figure 4-5 , in the embodiment of the present invention, a corn processing graded crushing device is different from embodiment 1 in that the inner bottom of the grinding tank 3 is provided with an extruding slope 37, and the grinding roller 22 is close to one end of the side wall of the grinding tank 3 There is a cut angle 38 that cooperates with the extrusion slope 37; through the cooperation of the extrusion slope 37 and the cut angle 38, the material in the grinding tank 3 can be prevented from being ground at the corner of the side wall of the grinding tank 3, and the grinding process is improved. Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com