A method for shaping the mandrel to elongate the ta15 high cylinder

A mandrel and high cylinder technology, which is applied in the field of cylinder forging, can solve the problems of high cost, cumbersome forging process, and reduce production cost, and achieve high material utilization rate, increase material utilization rate, and reduce blanking weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for shaping a mandrel to elongate a TA15 high cylinder, comprising the following steps:

[0036] (1) Blanking blank: According to the size of the blank, the TA15 bar raw material is blanked and sawed to obtain a TA15 blank; the size of the blank is (Φ300×706mm);

[0037] The main chemical element content of the TA15 bar is as follows in terms of mass percentage: 0.099% Fe, 0.042% C, 0.004% N, 0.0007% H, 0.12% O, and the balance elements are Ti and unavoidable impurities , and the total amount of impurities ≤ 0.30, single impurity content ≤ 0.10;

[0038] (2) Heating and heat preservation: heat the sawed TA15 billet to 40±10°C below the phase transition point and heat preservation treatment. The heat preservation time is: the effective thickness of the bar × 6min / 10mm;

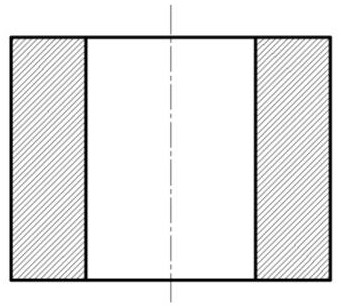

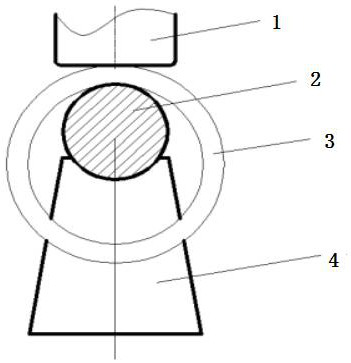

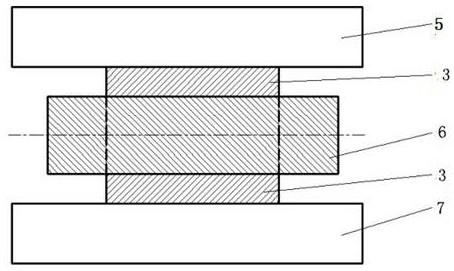

[0039](3) Punching and hole expansion: Punch and expand the TA15 blank that has been heat-preserved above to obtain a rectangular ring blank 1[Φ(366±10)×Φ(130±10)×(520±6)mm ]; The amount of de...

Embodiment 2

[0046] A method for shaping a mandrel to elongate a TA15 high cylinder, comprising the following steps:

[0047] (1) Blanking blank: According to the size of the blank, the TA15 bar raw material is blanked and sawed to obtain a TA15 blank; the size of the blank is (Φ300×706mm);

[0048] The main chemical element content of the TA15 bar is as follows in terms of mass percentage: 0.099% Fe, 0.042% C, 0.004% N, 0.0007% H, 0.12% O, and the balance elements are Ti and unavoidable impurities , and the total amount of impurities ≤ 0.30, single impurity content ≤ 0.10;

[0049] (2) Heating and heat preservation: heat the sawed TA15 billet to 40±10°C below the phase transition point and heat preservation treatment. The heat preservation time is: the effective thickness of the bar × 6min / 10mm;

[0050] (3) Punching and hole expansion: Punch and expand the TA15 blank that has been heat-preserved above to obtain a rectangular ring blank 1[Φ(366±10)×Φ(130±10)×(520±6)mm ]; The amount of d...

Embodiment 3

[0057] A method for shaping a mandrel to elongate a TA15 high cylinder, comprising the following steps:

[0058] (1) Blanking blank: According to the size of the blank, the TA15 bar raw material is blanked and sawed to obtain a TA15 blank; the size of the blank is (Φ300×706mm);

[0059] The main chemical element content of the TA15 bar is as follows by mass percentage: 0.057% of Fe, 0.0089% of C, 0.0054% of N, 0.0022% of H, 0.14% of O, and the remaining elements are Ti and unavoidable impurities , and the total amount of impurities ≤ 0.30, single impurity content ≤ 0.10;

[0060] (2) Heating and heat preservation: heat the sawed TA15 billet to 40±10°C below the phase transition point and heat preservation treatment. The heat preservation time is: the effective thickness of the bar × 6min / 10mm;

[0061] (3) Punching and hole expansion: Punch and expand the TA15 blank that has been heat-preserved above to obtain a rectangular ring blank 1[Φ(366±10)×Φ(130±10)×(520±6)mm ]; The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com