A method for manufacturing environmentally friendly wood-based panels from cotton stalks

An environmentally friendly wood-based panel and cotton stalk technology, which is applied in the field of panel manufacturing, can solve the problems of trialdehyde glue pollution, difficulty, and difficulty in wood-based panel technology, and achieve the effects of simple production process, low cost, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

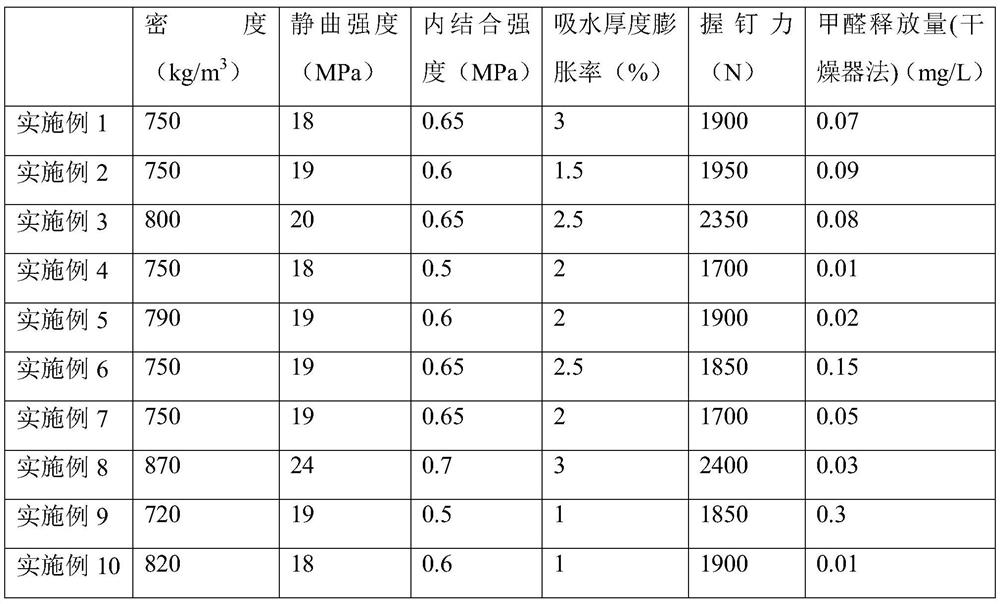

Examples

Embodiment 1

[0027] 5000g of cotton stalks with bolls and roots removed, the cotton stalks were separated by hand, branches, leaves, cortex and pith were removed to obtain 3000g of cotton stalk lignocellulosic components, which were processed into shavings and scraps by using a ring planer. Dried in a blast oven to a final moisture content of 3wt% for later use.

[0028] The branches, leaves, cortex and pith of cotton stalks separated by hand are 2000g raw materials, put into a pulverizer and crushed to below 80 mesh, take 1000g of crushed powder, add a mixed solvent composed of 600g of water, 4800g of ethanol, and 600g of phenol, and then add it to a 10L high-pressure In the stainless steel reactor, the temperature was raised from 25°C to 120°C at a rate of 5°C per minute, kept stirring at a speed of 400r / min, and the pressure inside the reactor was controlled at 0.8MPa, and kept for 20 minutes. After the reaction is completed, quickly pass cooling water to reduce the temperature in the r...

Embodiment 2

[0031] Remove 10,000 kg of cotton stalks with bolls and roots, use a cotton stalk skin core separator and a pulverizer to separate the cotton stalk core from the cotton stalk skin, remove branches, leaves, cortex and pith by winnowing, and obtain the lignocellulosic component of cotton stalks 7000Kg, after it is processed into shavings and scraps by a ring flaker, it is dried to a final water content of 4wt% by a drum dryer for subsequent use.

[0032] The 3000Kg of cotton stalk leaves, cortex and pith core obtained by winnowing are pulverized by a pulverizer to below 80 mesh, 1000Kg of crushed powder is taken, and a mixed solvent composed of 3000Kg of ethanol and 3000Kg of phenol is added to a 10000L high-pressure stainless steel reaction kettle to 5°C raise the temperature from 25°C to 120°C per minute, keep stirring at a speed of 400r / min, control the pressure in the reactor to 0.8MPa, and keep the pressure for 20 minutes. After the reaction is completed, quickly cool the bri...

Embodiment 3

[0036] Remove 10,000Kg of cotton stalks with bolls and roots, and use a cotton stalk skin-core separator to separate the cotton stalk core from the cotton stalk skin, remove branches, leaves, cortex, and pith by winnowing, and obtain 7,000Kg of cotton stalk lignocellulosic components. Crushed to less than 5 cm, put into an air-explosion tank, feed high-pressure steam, maintain the steam pressure at 1.5 MPa for 10 minutes, release the pressure to obtain steam-explosion cotton stalks, and dry to a final water content of 5 wt%.

[0037] Add 3000Kg of the remaining cotton stalk branches, leaves, cortex and pith to a pulverizer and crush it to below 80 mesh, take 1000Kg of crushed powder, add a mixed solvent composed of 3000Kg of ethanol and 3000Kg of phenol, and add it to a 10000L high-pressure reactor, and heat it at 5°C Raise the temperature to 120°C per minute, keep stirring at a speed of 400r / min, control the pressure in the reactor to 0.8MPa, and keep the pressure for 20 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com