Water absorbing plate of pressing mold

A technology for pressing molds and water-absorbing plates, which is applied in the direction of molds, manufacturing tools, mold auxiliary parts, etc., can solve the problems of cracking of fresh water drops, non-absorbing water, small volume of water storage chamber A, etc., and achieve uniform water pumping effect , Prevent cracking again, good water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

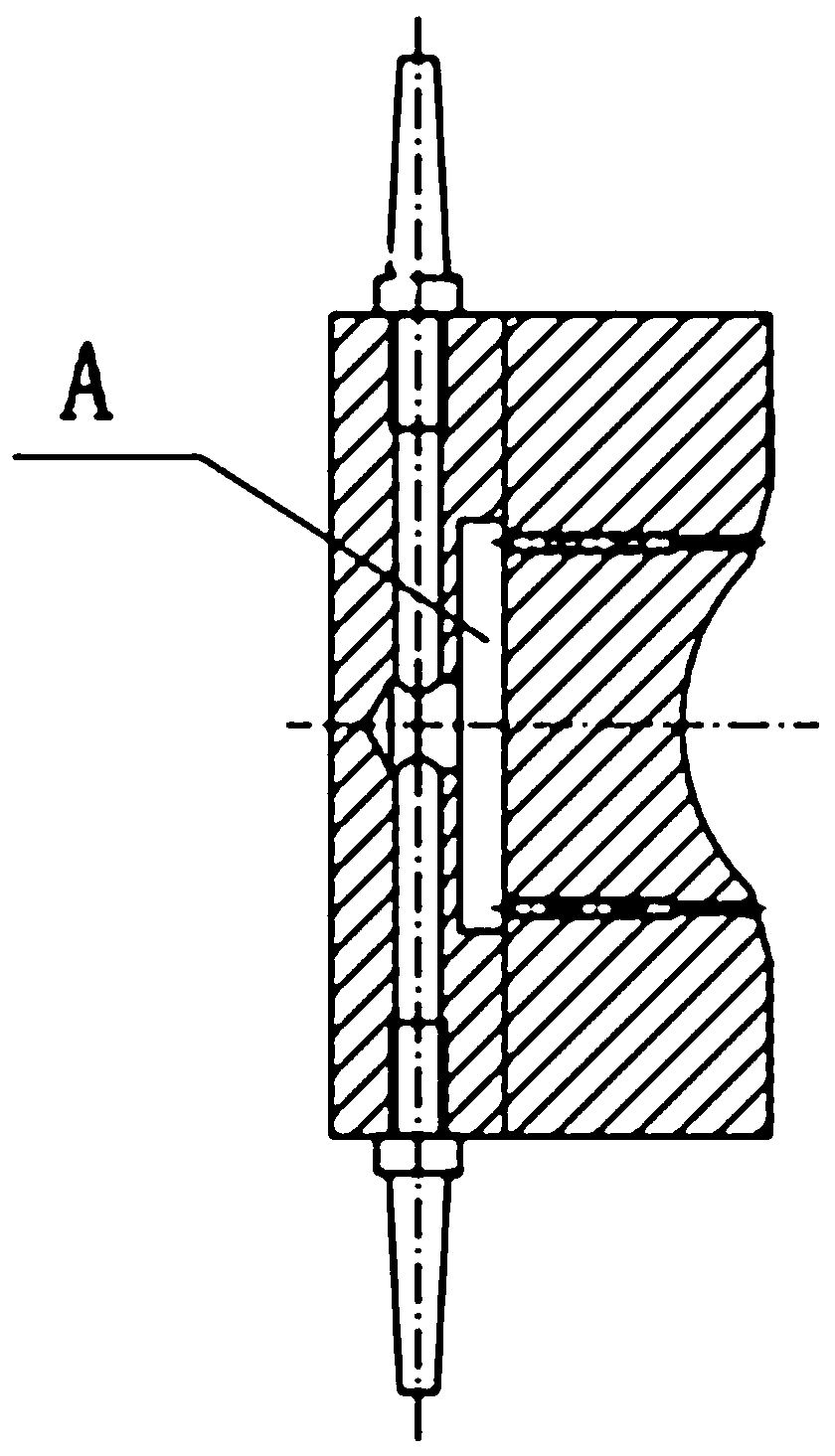

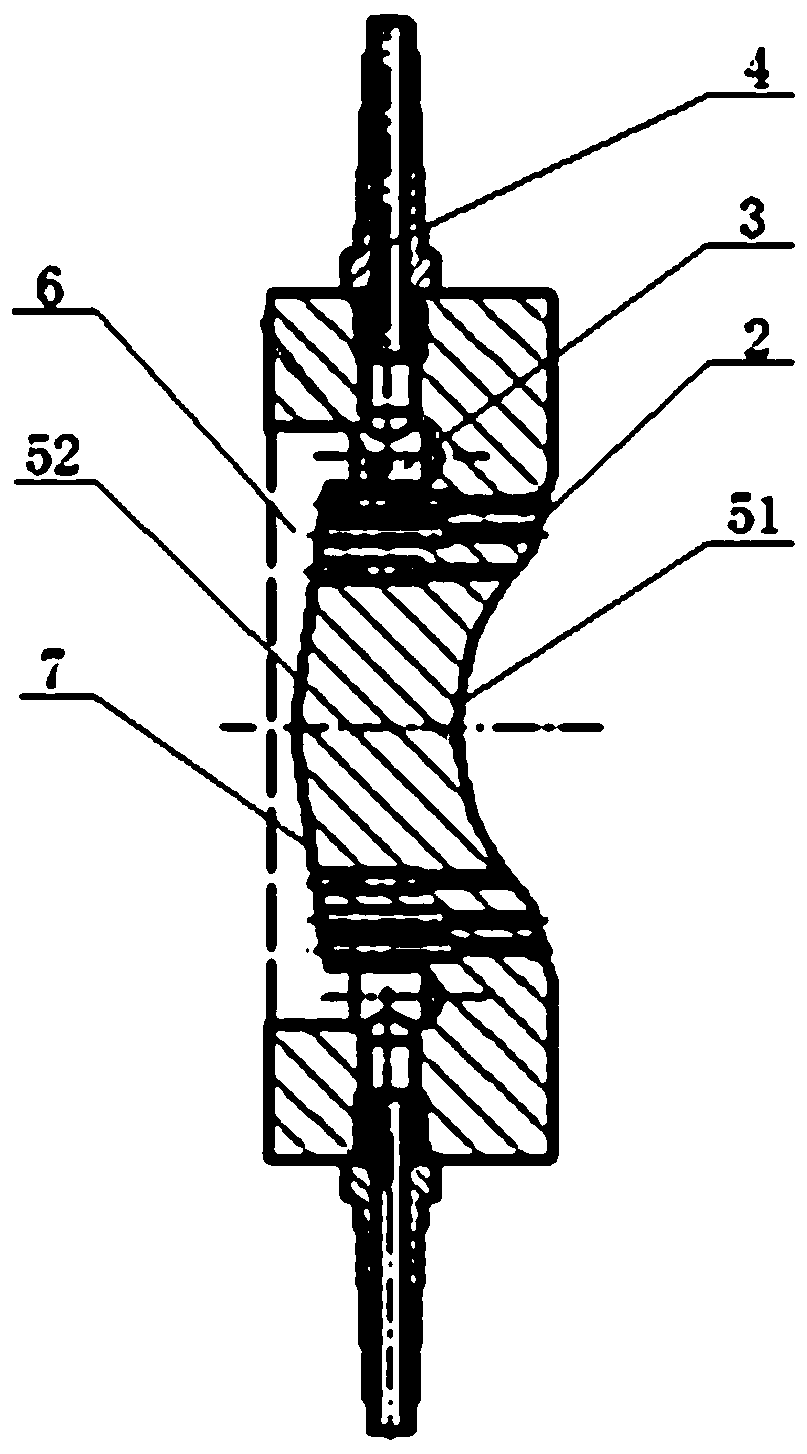

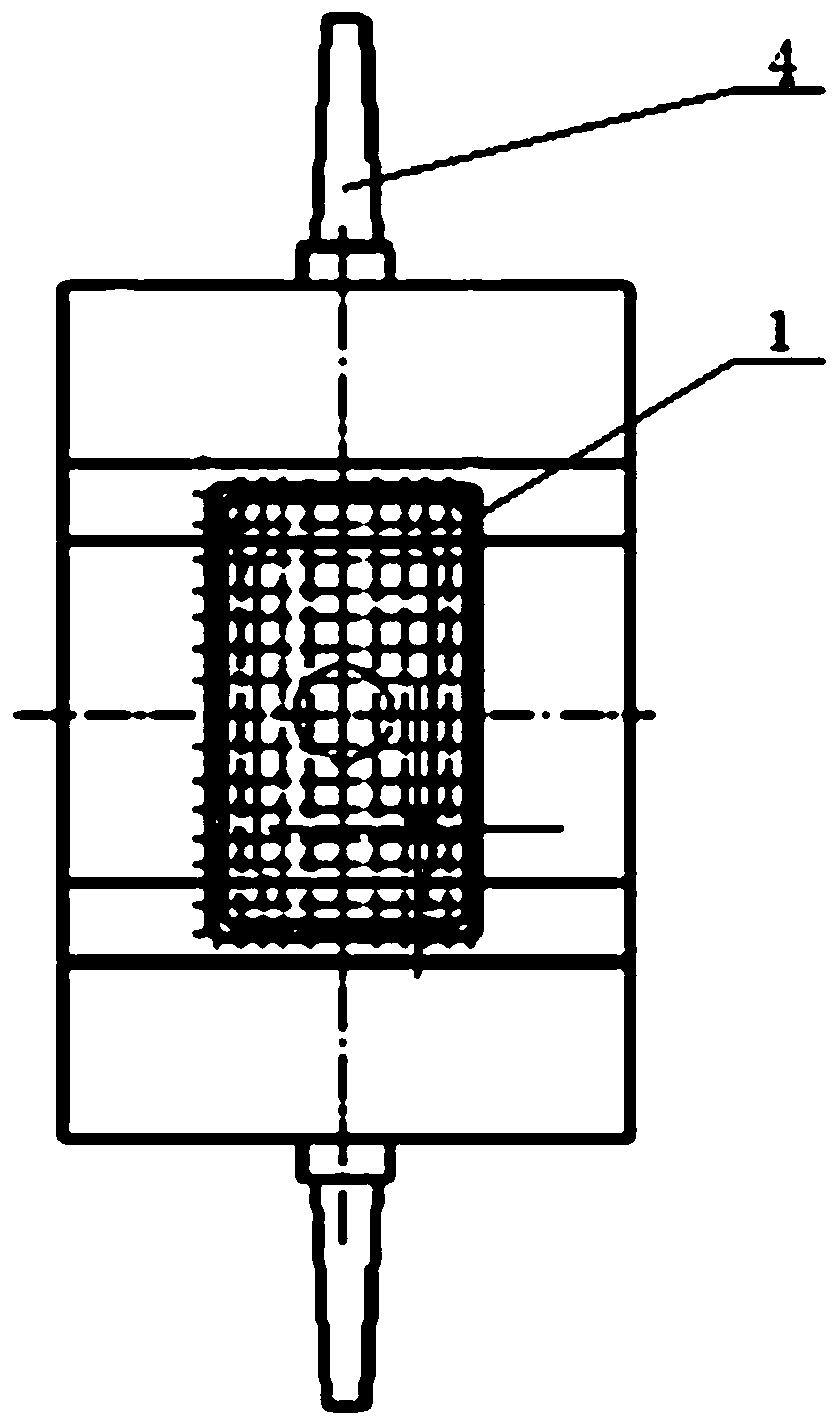

[0015] Such as Figure 2-4 As shown, the water-absorbing plate of the pressing mold introduced in this embodiment is provided with a water-absorbing groove 1 , a water-absorbing hole 2 , a water storage tank 3 and a water nozzle 4 .

[0016] The top and bottom of the water-absorbing plate are arc surfaces 5, the top is an inner arc surface 51, and the bottom is an outer arc surface 52. The circumference of the inner arc surface 51 is provided with a water absorption groove 1, which is pressed by a press and matched with the green body. The water absorption holes 2 are symmetrically arranged on both sides of the arc surface 5, and the number of each side is 3, which are connected to the inner arc surface. 51 and outer arc surface 52.

[0017] The water on the curved surface of the green body is directly sucked into the water storage tank, which not only can be directly sucked away, but also will not drip on the curved surface of the green body.

[0018] The outer end of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com