Kitchen waste transfer tank

A technology for kitchen waste and transfer boxes, which is applied in the directions of garbage receptacle, transportation and packaging, can solve the problems of limited single feeding capacity, limited feeding capacity, and large size of the space occupied by the container, and achieves the limit capacity. Simple and reliable, increased pouring angle, reliable and strong power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

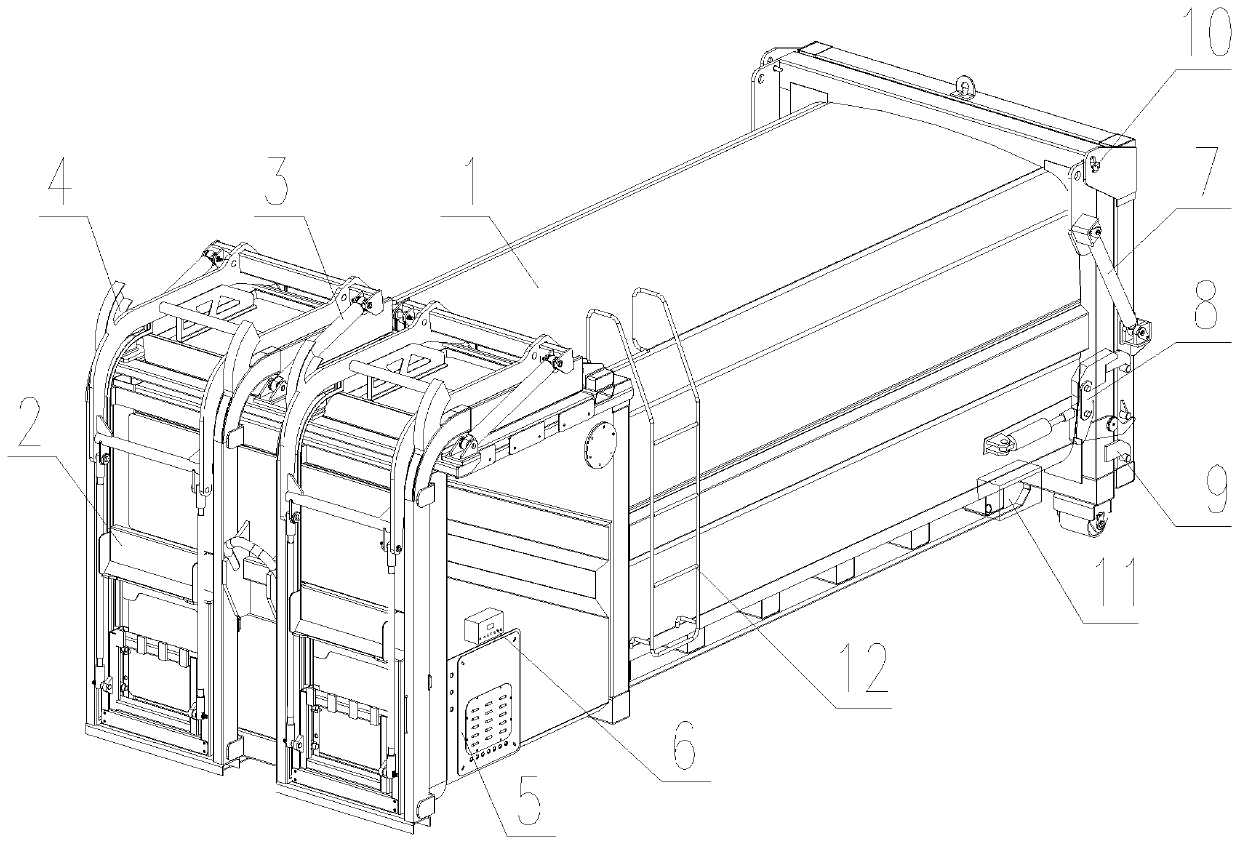

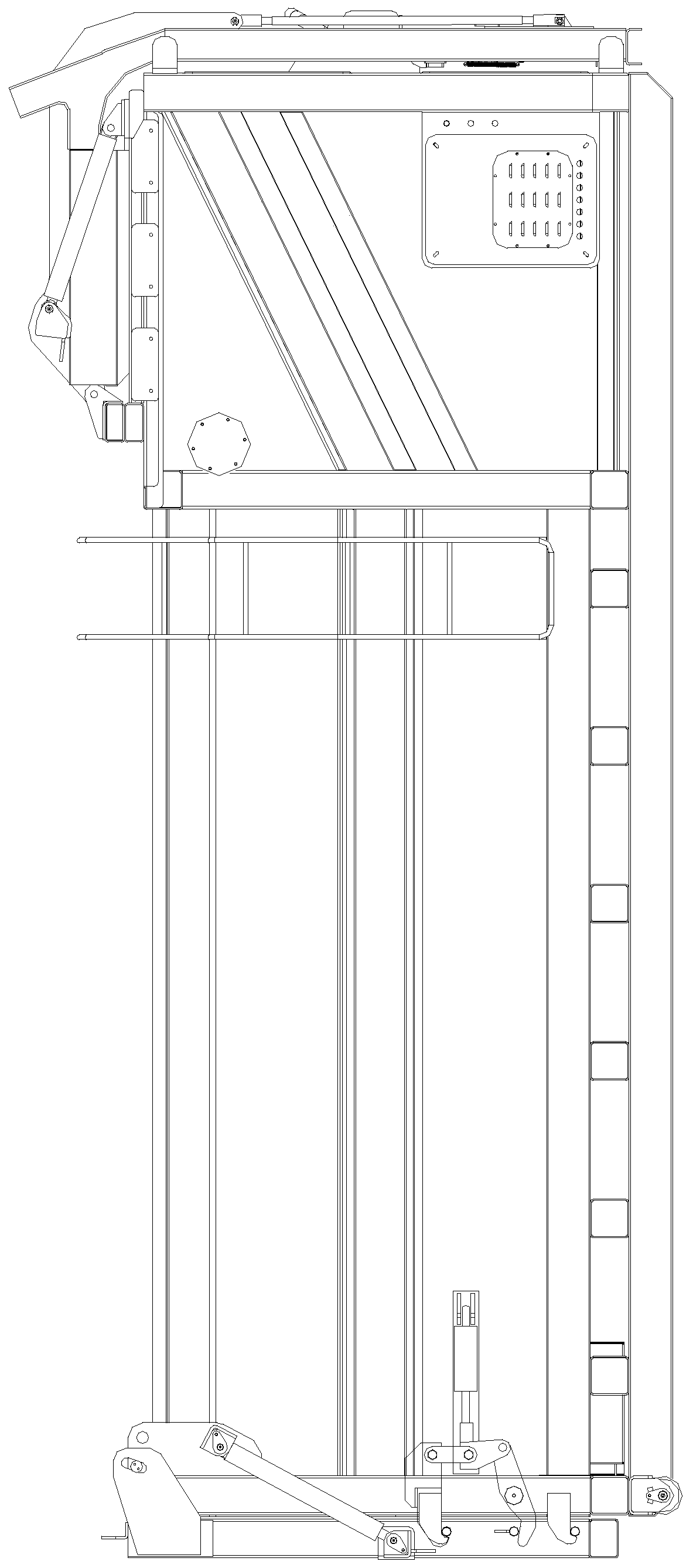

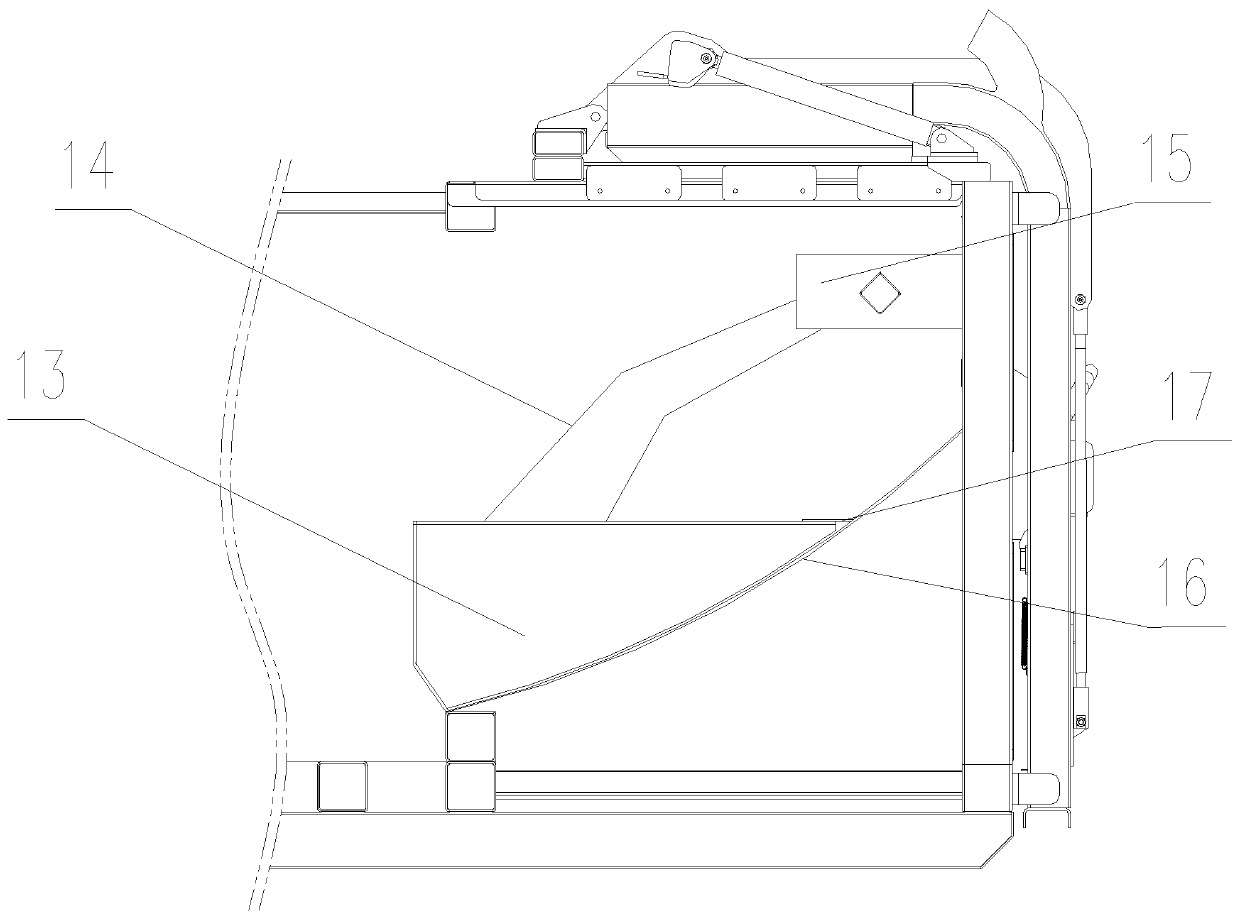

[0040] Such as Figure 1~5 As shown, it shows a specific embodiment of the present invention, a kind of food waste transfer box, comprising a square box 1, the front end of the square box hooks the box surface, and the rear end of the square box is equipped with a tailgate;

[0041] The hook box surface is equipped with a lifting device assembly for pouring garbage in the garbage can into the square box; Clamping mechanism; the lifting device assembly also includes a push hydraulic cylinder 3 that provides power for the hanging bucket lifting mechanism 2; the hanging bucket lifting mechanism 2 is fixedly installed on the guide rails on both sides by the rollers on both sides, and the guide rails on both sides Extending from the hook box surface to the garbage dump on the top surface of the square box body, the corner part of the guide rail is provided with an outer ear guide rail 4 that extends outward and is used to guide the rollers to the inside; the above also includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com