Swing bar type waste dumping and collecting device

A collection device and waste technology, which is applied in the field of domestic and construction waste collection equipment, can solve the problems of incompleteness, high work intensity, pollution, etc., and achieve the effects of long service life, high operating efficiency and good collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

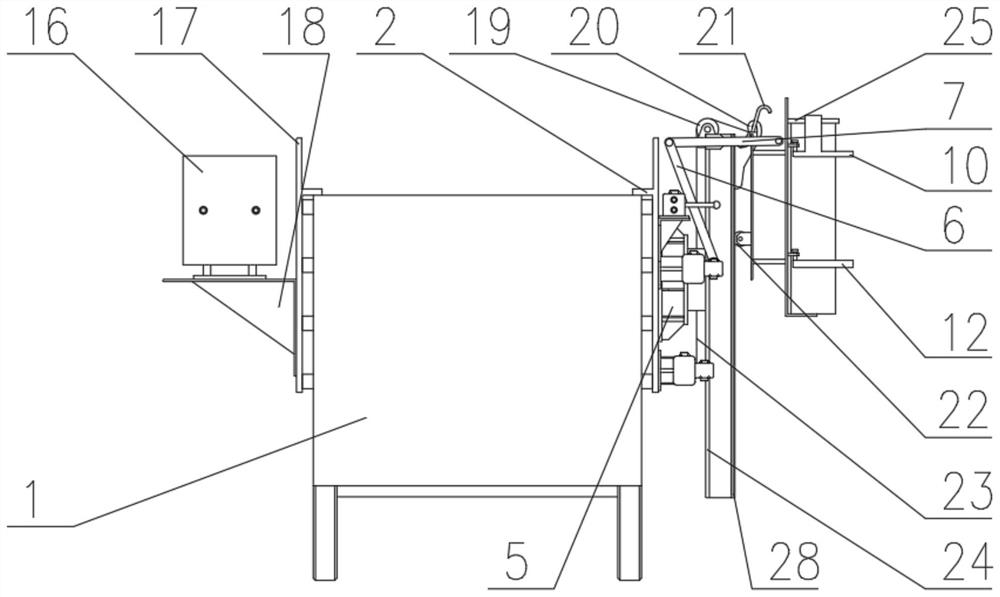

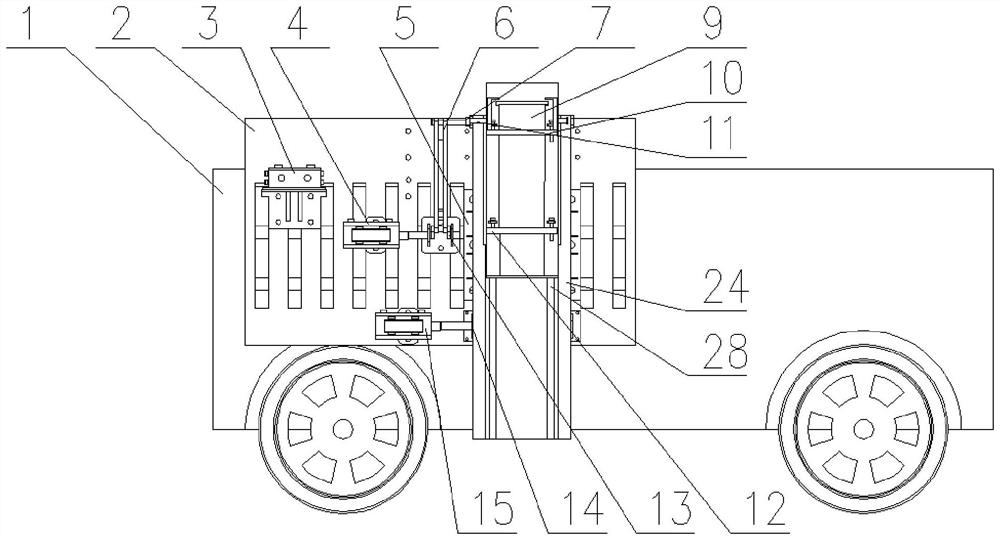

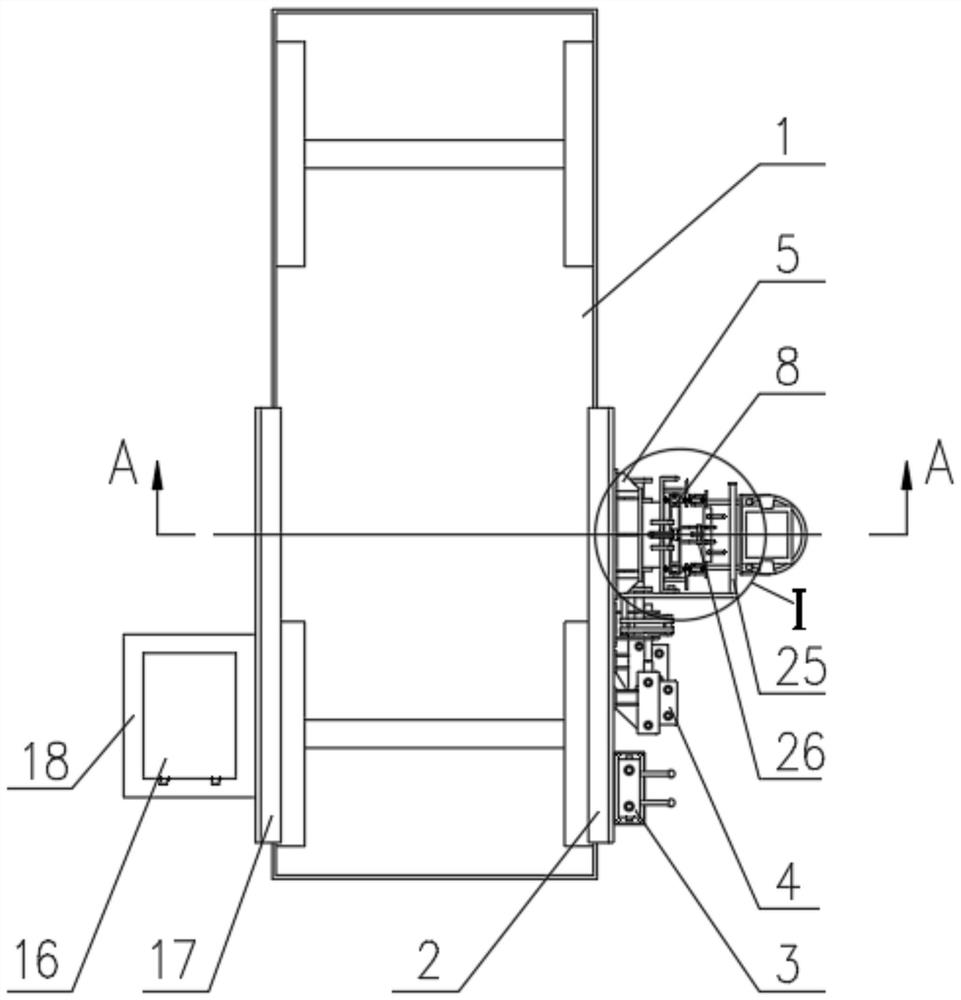

[0013] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. A swinging lever type waste dumping and collecting device, a right connecting plate 2 and a left connecting plate 17 are respectively installed on opposite sides of the waste bin 1, and a hydraulic pump 16 is installed on the left connecting plate 17 through a bracket 18 ; Install the electromagnetic reversing valve 3, the hydraulic motor A4, the hydraulic motor B15, the connecting frame 5, the hoist 14 and the crankshaft 13 respectively on the right connecting plate 2, and the hydraulic pump 16 is connected to the electromagnetic reversing valve 3 through the oil pipe. Communication, the electromagnetic reversing valve 3 is respectively connected with the hydraulic motor A4 and the hydraulic motor B15 through the oil pipe, the hydraulic motor B15 is connected with the winch 14, the hydraulic motor A4 is connected with the crankshaft 13, and one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com