Optical fiber production Japanese wire drawing furnace with automatic alarm function

An automatic alarm and wire drawing furnace technology, applied in manufacturing tools, glass manufacturing equipment, etc., can solve problems such as poor heat dissipation, waste of resources, unfavorable automatic control, etc., to improve shock absorption effect, ensure smooth operation, and improve heat dissipation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

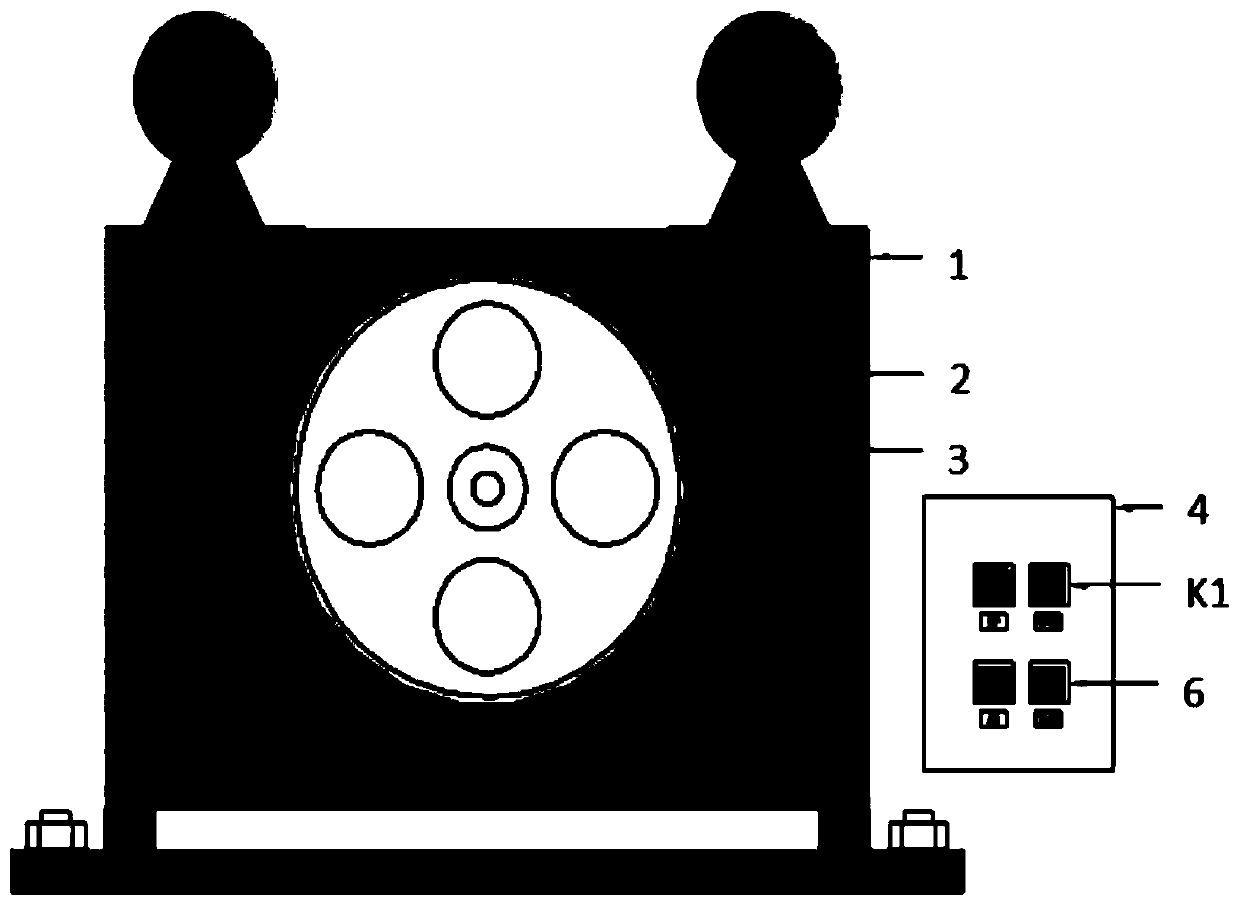

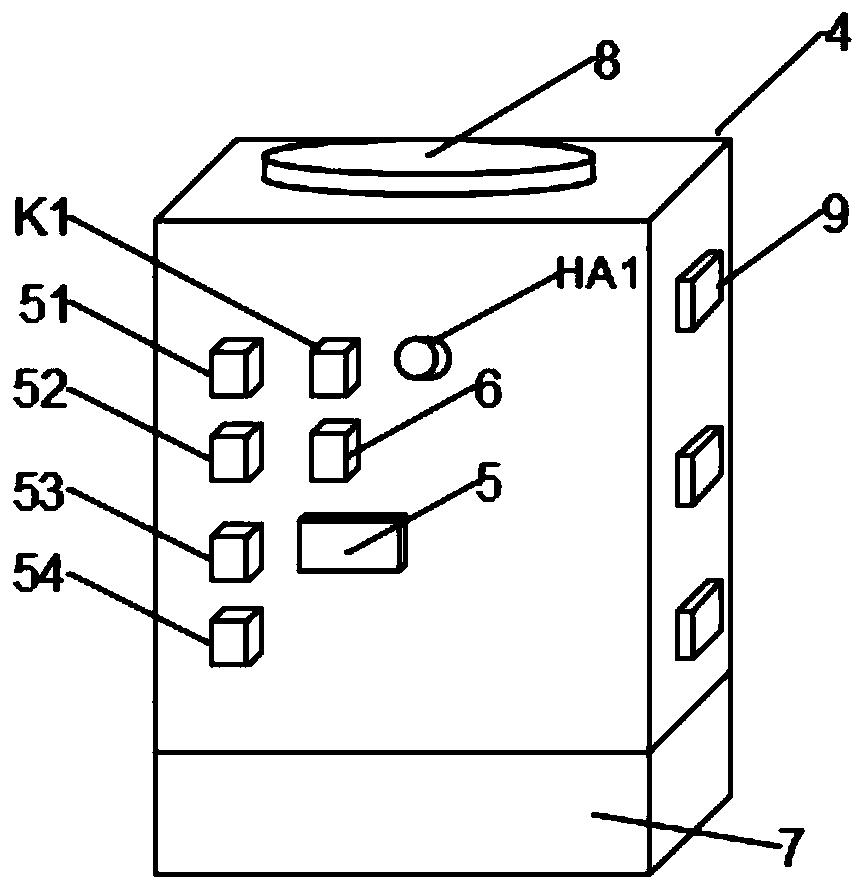

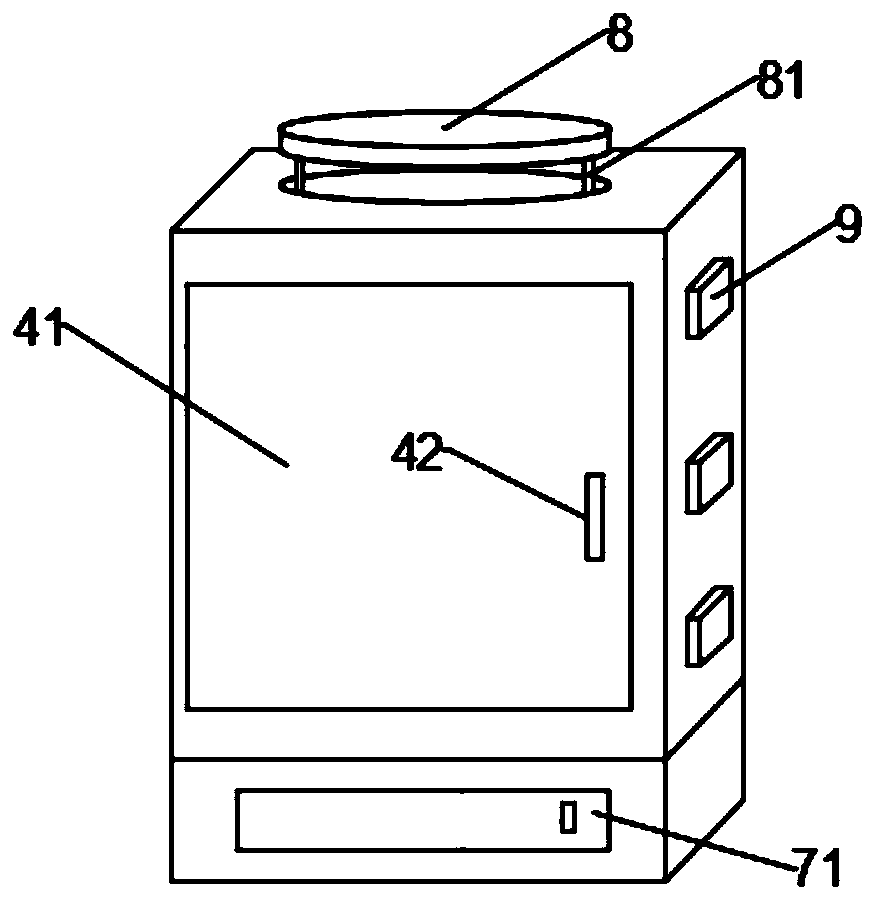

[0038] Such as Figure 1-8 As shown, a Japanese-style drawing furnace for optical fiber production with an automatic alarm function includes a main tower body support plate 1 and a main control cabinet 4, a traction disc device 2 is installed on the upper part of the main tower body support plate 1, and the side of the traction disc device 2 is auxiliary installed There is a pressure wheel device 3, and the traction disc device 2 is connected with the main control cabinet 4. The main control cabinet 4 is provided with a manual button K1 and an alarm indicator light HA1. The main control cabinet 4 is equipped with an isolation signal converter A01, a first middle Relay, second intermediate relay, digital output module OUT3 and power supply 12;

[0039]The first intermediate relay includes the first intermediate relay coil KA1 and the first intermediate relay normally open contact KA11, the second intermediate relay includes the second intermediate relay coil KA2 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com