A kind of preparation method of carbon nanotube composite ceramic network modified water-based non-stick coating

A carbon nanotube composite, carbon nanotube technology, used in anti-corrosion coatings, coatings and other directions, can solve the problems affecting the physical and mechanical properties and anti-corrosion effect of anti-corrosion coatings, large acid pollution, easy to be damaged, etc. Good performance, good adhesion, easy to industrialize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

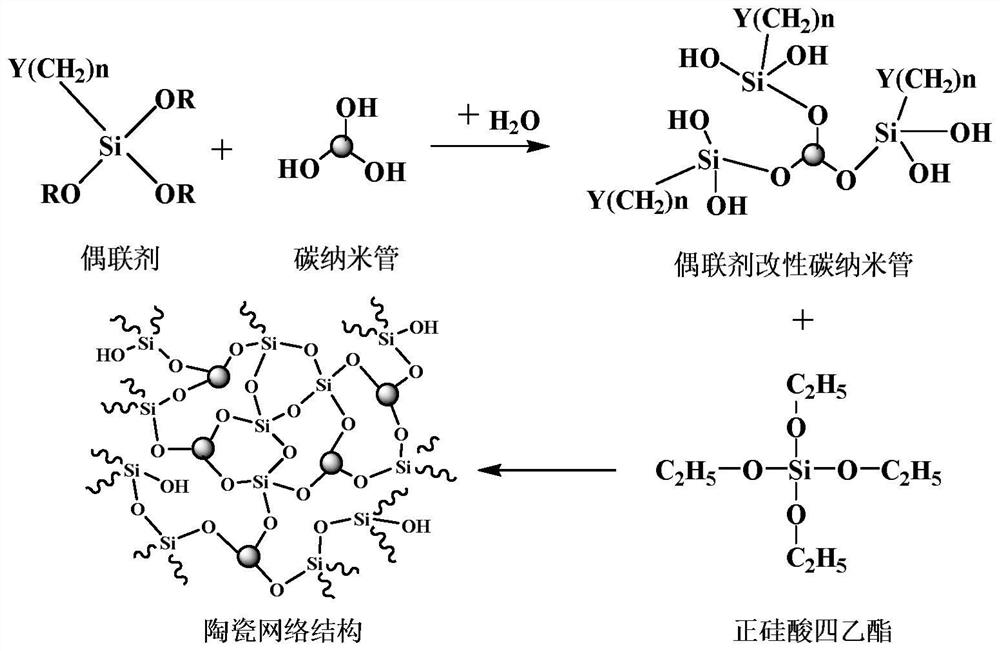

[0046] A method for preparing a carbon nanotube composite ceramic network modified water-based non-stick coating, comprising the following steps:

[0047] 1) Pre-dispersion of carbon nanotubes: disperse carbon nanotubes in water through a pre-dispersion process to form a carbon nanotube slurry with a concentration of 2-30 wt%. The pre-dispersion process is ultrasonic or grinding or adding a dispersant or a combination thereof.

[0048] 2) Modification of carbon nanotubes: divided into scheme 2.1) or scheme 2.2):

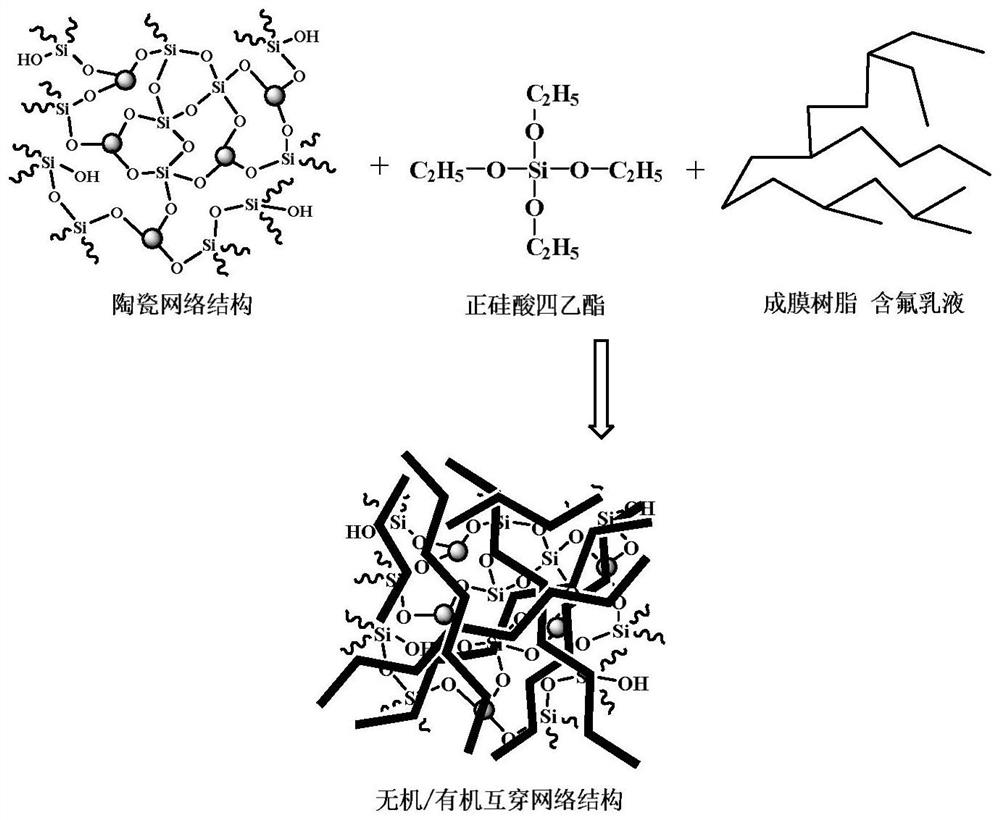

[0049] 2.1) Blend the carbon nanotube slurry prepared in step 1) with the silane coupling agent, stir and react at 200-300 rpm at room temperature for 2-4 hours, then add tetraethyl orthosilicate, adjust the pH to 1-4, and raise the temperature Stir and react at 40-80°C for 2-5 hours and then filter to obtain carbon nanotubes modified in situ by the ceramic network; the mass ratio of carbon nanotubes, silane coupling agent and tetraethyl orthosilicate is 20-4:1:1.1 ...

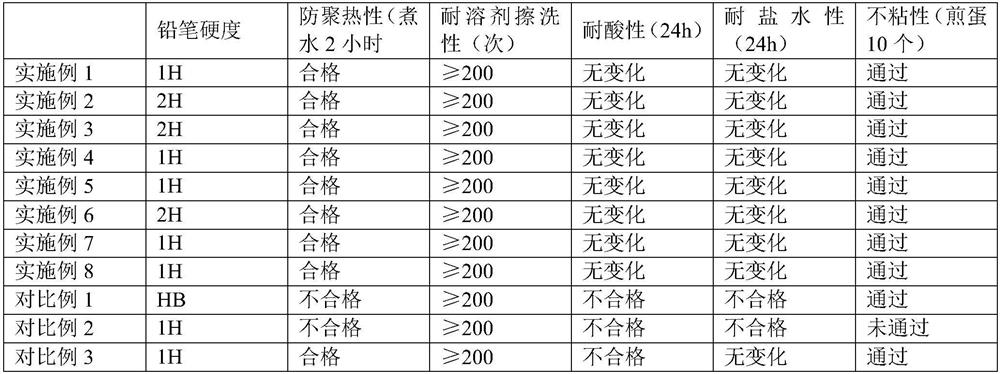

Embodiment 1

[0055] 1) Dispersing carbon nanotubes in water through an ultrasonic dispersion process to form a carbon nanotube slurry with a mass fraction of 2%;

[0056] 2) Blend the carbon nanotube slurry with γ-(2,3-glycidoxy)propyltrimethoxysilane, mechanically stir (200rpm) in the reaction flask for 2 hours at room temperature, and then add orthosilicate Ethyl ester, adjust the pH to 4, and filter at 80°C for 2 hours after stirring to obtain carbon nanotubes modified in situ by the ceramic network; carbon nanotubes, γ-(2,3-glycidyloxy)propyltrimethoxy The mass ratio of base silane and tetraethyl orthosilicate is 4: 1: 1.1;

[0057] 3) Premix the PTFE emulsion and tetraethyl orthosilicate, then add the carbon nanotubes modified in situ by the ceramic network, stir and react for 2 hours at 80°C, then add PES, carbon black, ceramic powder, dispersant, leveling agent, defoamer, thickener and water to obtain a composite modified water-based non-stick coating; the mass ratio of PTFE emulsi...

Embodiment 2

[0059] 1) Dispersing carbon nanotubes in water through a grinding and dispersing process to form a carbon nanotube slurry with a mass fraction of 30%;

[0060] 2) Blend the carbon nanotube slurry with β-(3,4 epoxycyclohexyl)-ethyltrimethoxysilane, mechanically stir (300rpm) in the reaction flask for 4 hours at room temperature, and then add orthosilicate Ethyl ester, adjust the pH to 1, filter at 40°C after stirring for 5 hours to obtain carbon nanotubes modified in situ with the ceramic network; carbon nanotubes, β-(3,4 epoxycyclohexyl)-ethyltrimethoxy The mass ratio of base silane and tetraethyl orthosilicate is 20: 1: 2.0;

[0061] 3) Premix PTFE emulsion, PFA emulsion and tetraethyl orthosilicate, then add carbon nanotubes modified in situ by ceramic network, stir and react for 5 hours at 40°C, then add PES, PAI, iron red, silicon carbide, Dispersants, leveling agents, defoamers, thickeners and water to obtain composite modified water-based non-stick coatings; PTFE emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com