A prefabricated friction metal double energy dissipation shock-absorbing steel frame beam-column joint

A beam-column joint and frame beam technology, applied in earthquake-proof, protective buildings/shelter, building type, etc., can solve the problems of difficult repair, large damage to the main structure, weak energy consumption capacity, etc. The effect of cumulative ductility and energy dissipation capacity, convenient seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

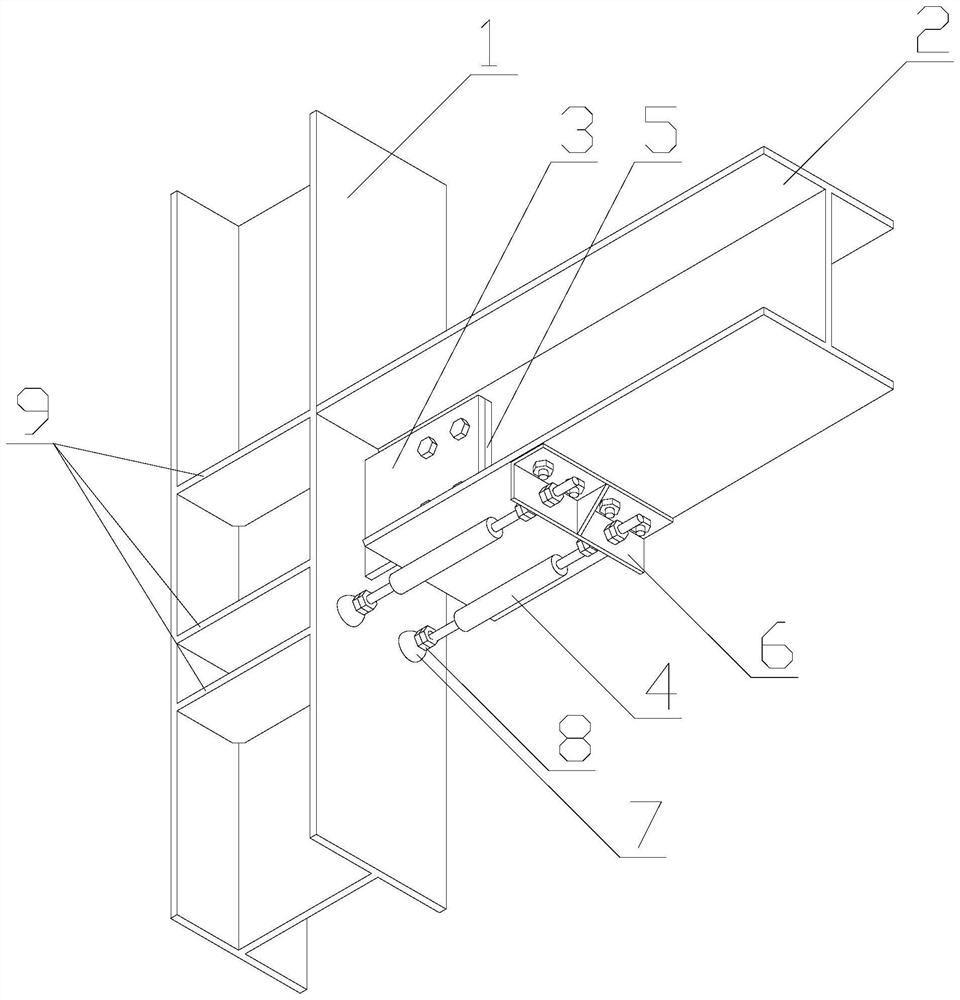

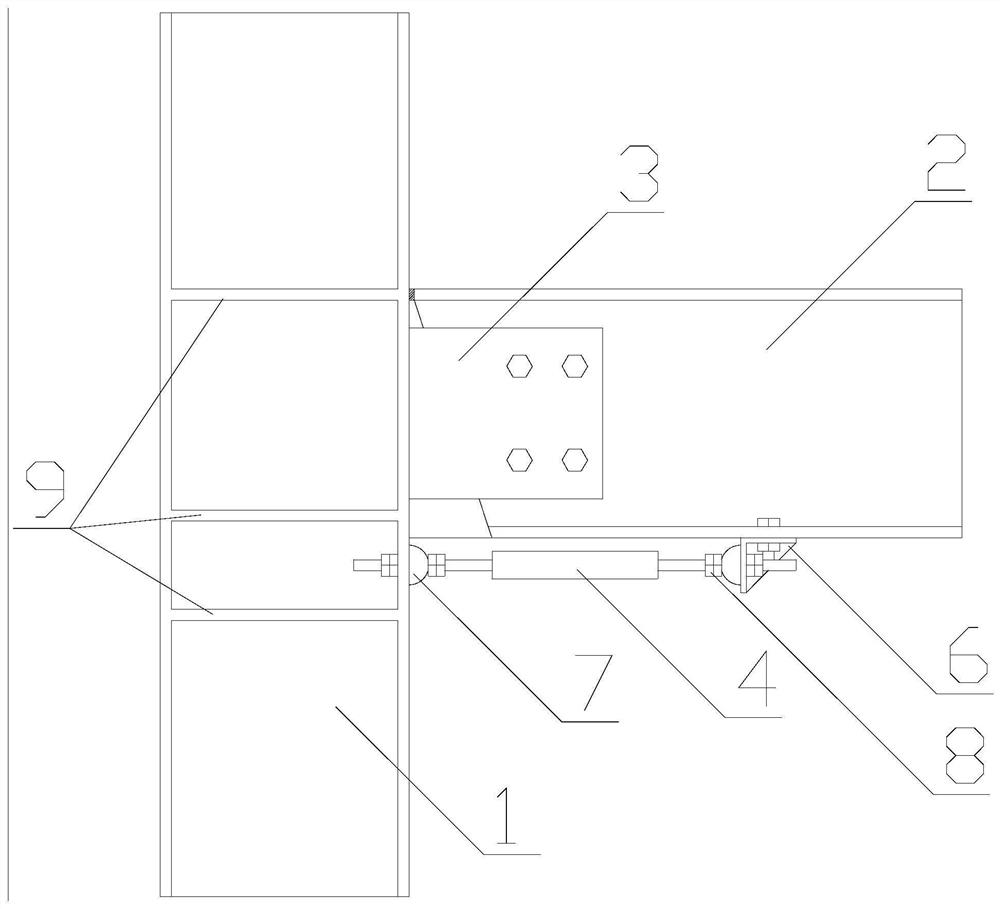

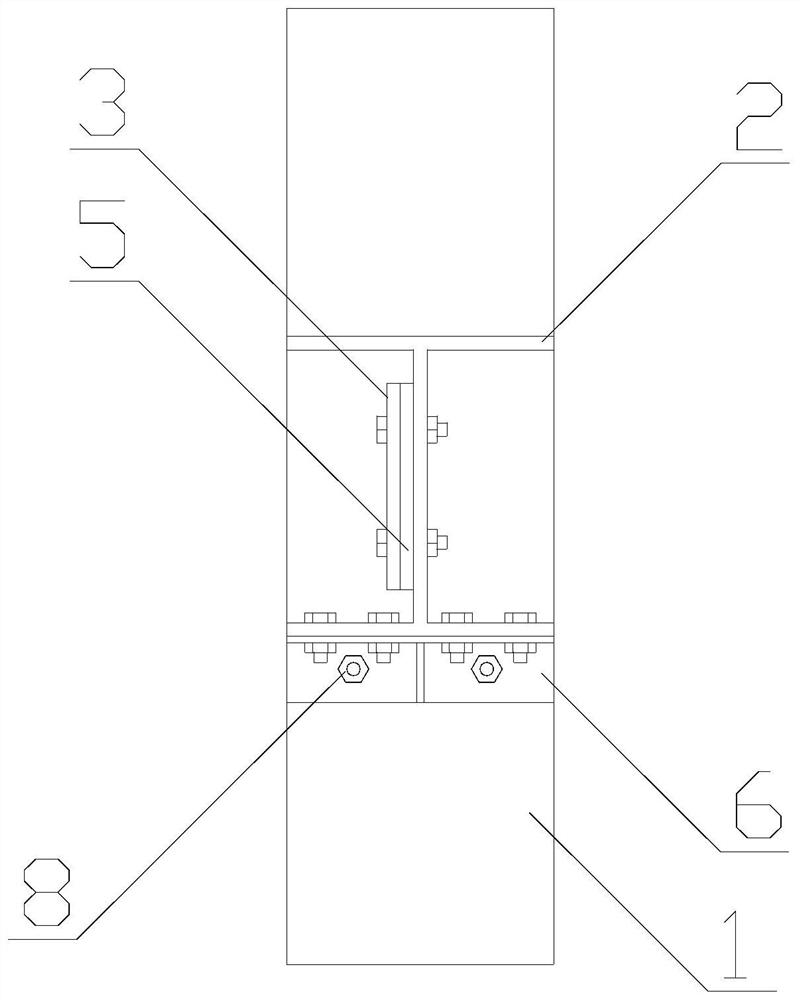

[0013] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0014] refer to Figure 1-Figure 4 , the assembled friction metal double energy-dissipating shock-absorbing steel frame beam-column node of the present invention includes a frame column 1 and a frame beam 2, the frame column 1 is continuous, the frame beam 2 is disconnected, and a beam-column connection plate 3 is also included , high-hardness friction plate 5 and metal energy-dissipating connection components. The cross-sections of frame column 1 and frame beam 2 are both H-shaped or rectangular tube or steel-concrete composite cross-section. Stiffeners 9 are provided, and the stiffeners 9 are symmetrically arranged left and right. The upper flange of the frame beam 2 is fixedly connected to the side flange of the frame column 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com