Camellia seed oil powder rich in squalene and DHA

A technology of camellia oleifera seed oil and squalene, which is applied in the direction of fat oil/fat production, fat oil/fat refining, and fat production, can solve the problems of waste of natural active substances, loss of active ingredients, loss of oil-soluble substances, etc., and reduce production Effects of energy consumption, nutritional balance, and ease of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] A preparation method of Camellia oleifera seed oil solid powder rich in squalene and DHA, comprising the steps of:

[0032] 1. Obtaining crude oil

[0033] Camellia oleifera seeds are pressed at low temperature to obtain squeezed oil, and the squeezed oil is filtered to obtain crude oil of camellia oleifera seeds with an impurity content of less than 0.2 wt%.

[0034] 2. Refining

[0035] (1) Degumming: Degumming: Slowly add 10 parts by weight of warm water (water temperature is 35±5°C) to 100 parts by weight of tea seed crude oil, stir while adding warm water, keep stirring for 10 to 15 minutes, and then let it stand for 3 to 5 minutes After 4 hours, settling and separating, removing the impurities and water in the lower layer to obtain primary degummed oil; slowly add 5 parts by weight of warm water to 100 parts by weight of primary degummed oil, stir while adding warm water, continue stirring for 10 to 15 minutes, and then let it stand After 3 to 4 hours, settle an...

Embodiment 1

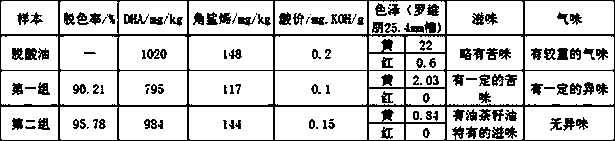

[0041] Camellia seed oil degumming

[0042] Crude oil was obtained by low-temperature pressing of Camellia oleifera seeds picked in the same year, and the tested crude oil was divided into two groups. The first group of crude oil is degummed by the traditional method: slowly add 15 parts by weight of warm water at a temperature of 35°C to 100 parts by weight of crude oil, stir while adding water, keep stirring for 12 minutes, then stand for 3.5 hours, and use sedimentation after standing After the separation method removes the impurities and water in the lower layer, the degummed oil is obtained. The second group of crude oil uses the degumming process of the present invention, and its process parameters are: slowly add 10 parts by weight of warm water at a temperature of 35°C to 100 parts by weight of tea seed crude oil, stir while adding warm water, continue to stir for 12 minutes, and then statically Settled and separated for 3.5 hours, removed the lower layer of impuritie...

Embodiment 2

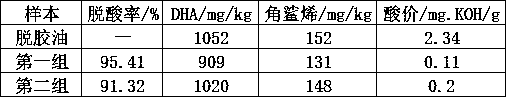

[0046] Camellia seed oil deacidification

[0047] Use the second group of degummed tea seed oil in Example 1 as the deacidification material, and the first group of degummed oil is deacidified by the traditional method. The process parameters are: use 100 parts by weight of degummed oil, heat the degummed oil to 45 ° C, add 3 parts by weight of sodium hydroxide solution with a concentration of 12%, stirred for 30 minutes to neutralize the free acid in camellia oleifera oil; then 15 parts by weight of water at 80°C were added to the mixture, stirred and washed and left to stand for 4 hours, separated by sedimentation Remove water and soapstock to obtain deacidified oil. The second group of degummed oils adopts an excess alkali deacidification process (technique of the present invention): with 100 parts by weight of degummed oils, heated to 45 ° C, adding 2 parts by weight of a concentration of 10% sodium hydroxide solution, stirred for 30 minutes ; Then add 15 parts by weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com