Maintenance wallboard and wall system thereof

A wall panel and panel body technology, applied in the direction of covering/lining, building, building structure, etc., can solve the problems of generating dense smoke, melting quickly, maintaining wall panel collapse, etc., to reduce weight, increase overall thickness, reduce The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

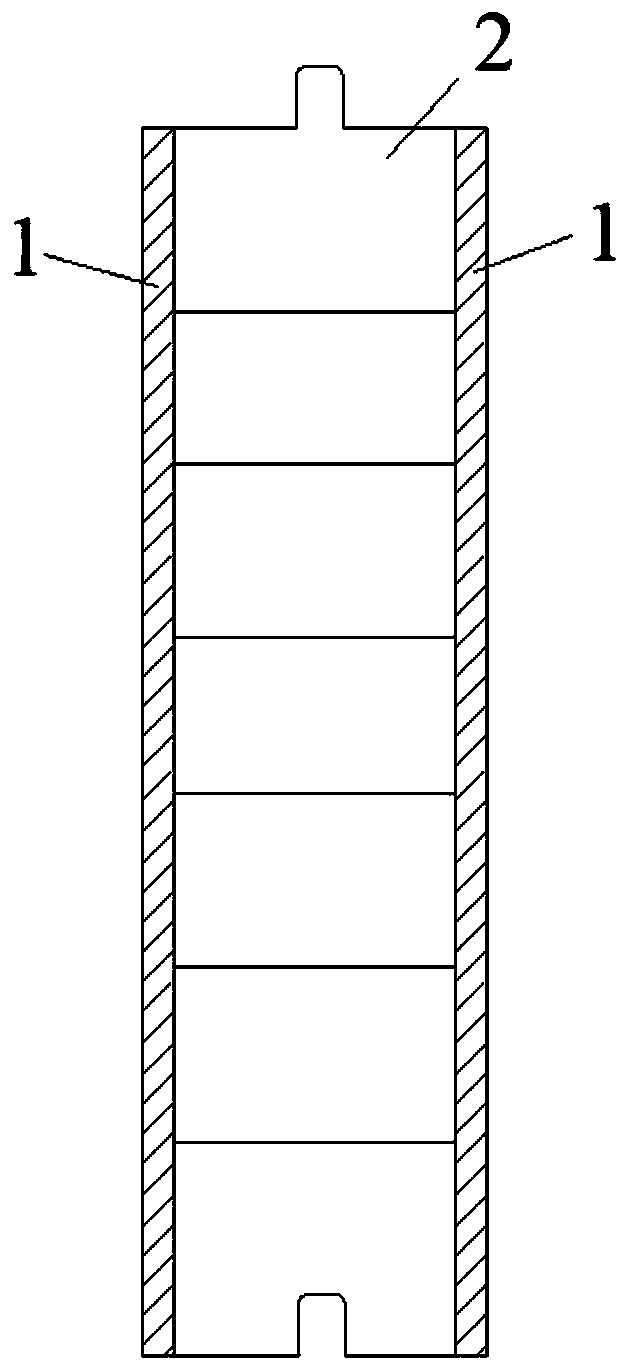

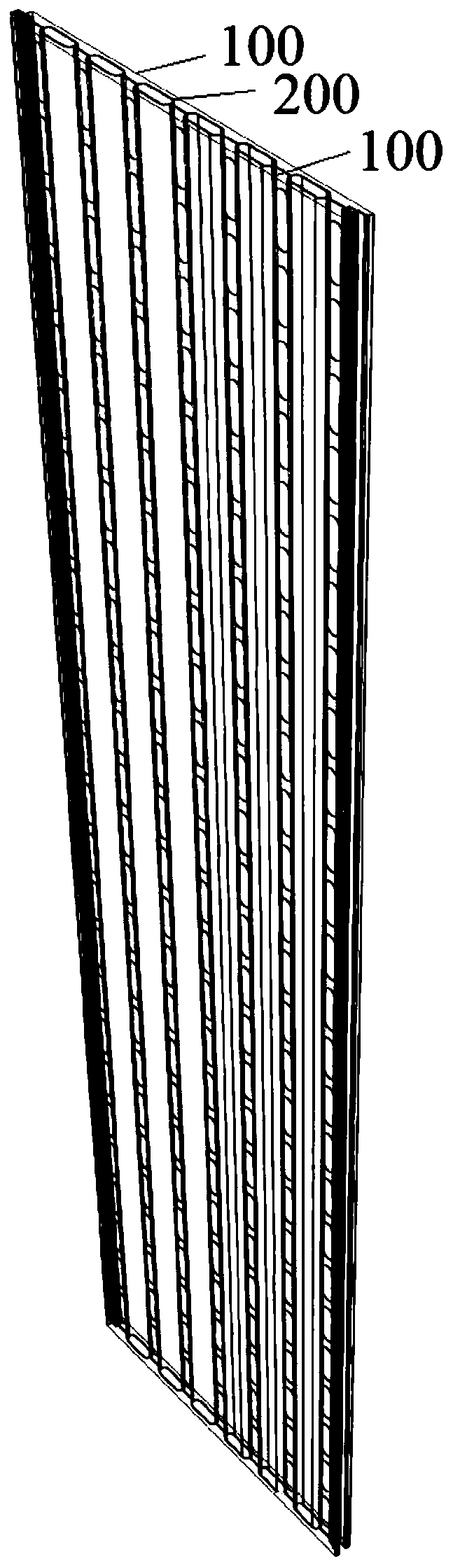

[0068] image 3 and Figure 4 It is a structural schematic diagram of the maintenance wall panel provided in the embodiment of the present application. The maintenance wall panel includes an inner rib structure 200 and inorganic material filling panels 100 arranged on both sides of the inner rib structure 200 . In the embodiment of the present application, the inorganic material filled board 100 is a glass magnesium board, and the internal rib structure 200 has undergone a special structural design.

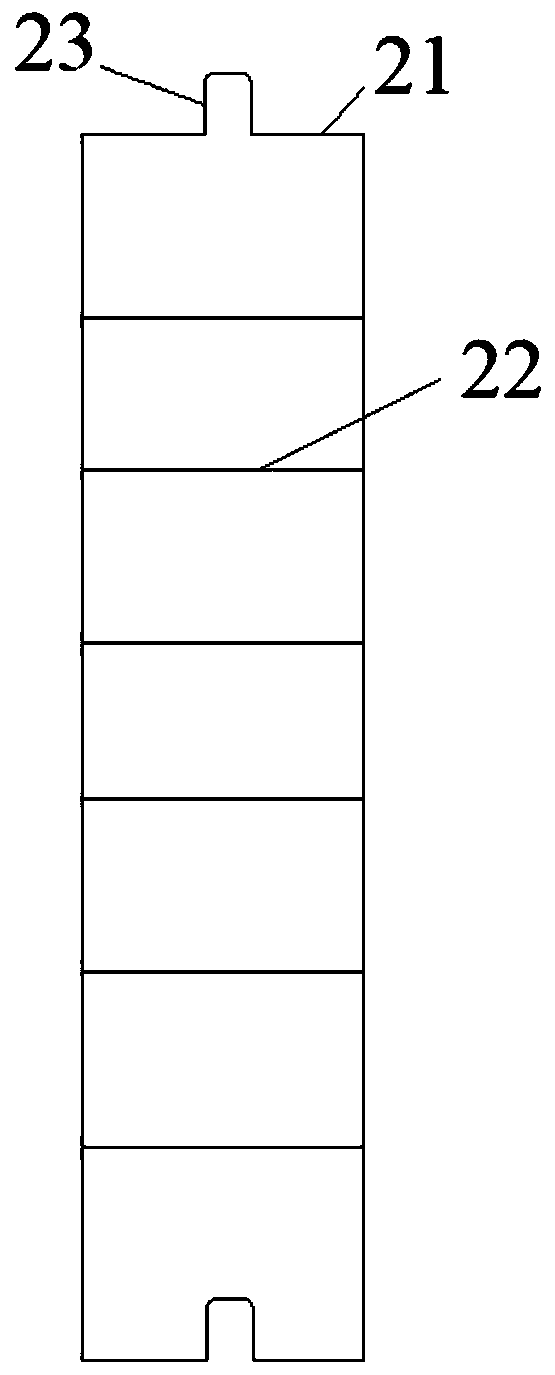

[0069] Such as Figure 5 ~ Figure 7 As shown, the inner rib structure 200 includes multiple sets of through plates 10 and multiple sets of connecting plates 20. Both the through plates 10 and the connecting plates 20 are rectangular strip structures. The through plates 10 and the connecting plates 20 are arranged at intervals and arranged in sequence to form a whole rectangular inner ribs.

[0070] In the embodiment of the present application, both the through plate 10 and the...

Embodiment 2

[0087] Figure 10 It is the front view of the maintenance wall panel provided in the embodiment of the present application. The maintenance wall panel provided in the embodiment of the application is generally the same as the embodiment 1, and the only difference is that the assembled connectors at both ends of the maintenance wall panel are female groove connections pieces.

[0088] When the above-mentioned maintenance wallboards are in use, the female groove connectors at the ends of the two maintenance wallboards are fixed by a special fixed connector, and the fixed connectors are fixed to the heavy steel structure building. Suitable for building walls of heavy steel structure.

Embodiment 3

[0090] Figure 11 It is a schematic structural diagram of the maintenance wallboard provided in the embodiment of the present application. The maintenance wallboard provided in the embodiment of the application is generally the same as the embodiment, and the only difference is:

[0091] A glass fiber mesh 300 is arranged inside the inorganic material filled board 100 , and the glass fiber mesh 300 may be one layer or multiple layers, and is evenly arranged in the inorganic material filled board 100 .

[0092] The arrangement of the glass fiber mesh 300 can further enhance the strength of the entire maintenance wallboard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com