Drying and cleaning machine

A washing machine and chassis technology, applied in dryers, drying, garbage drying and other directions, can solve the problems affecting the efficiency and quality of the garbage screening process, achieve drying and cleaning, improve cleanliness and dryness, prolong The effect of the conveying path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

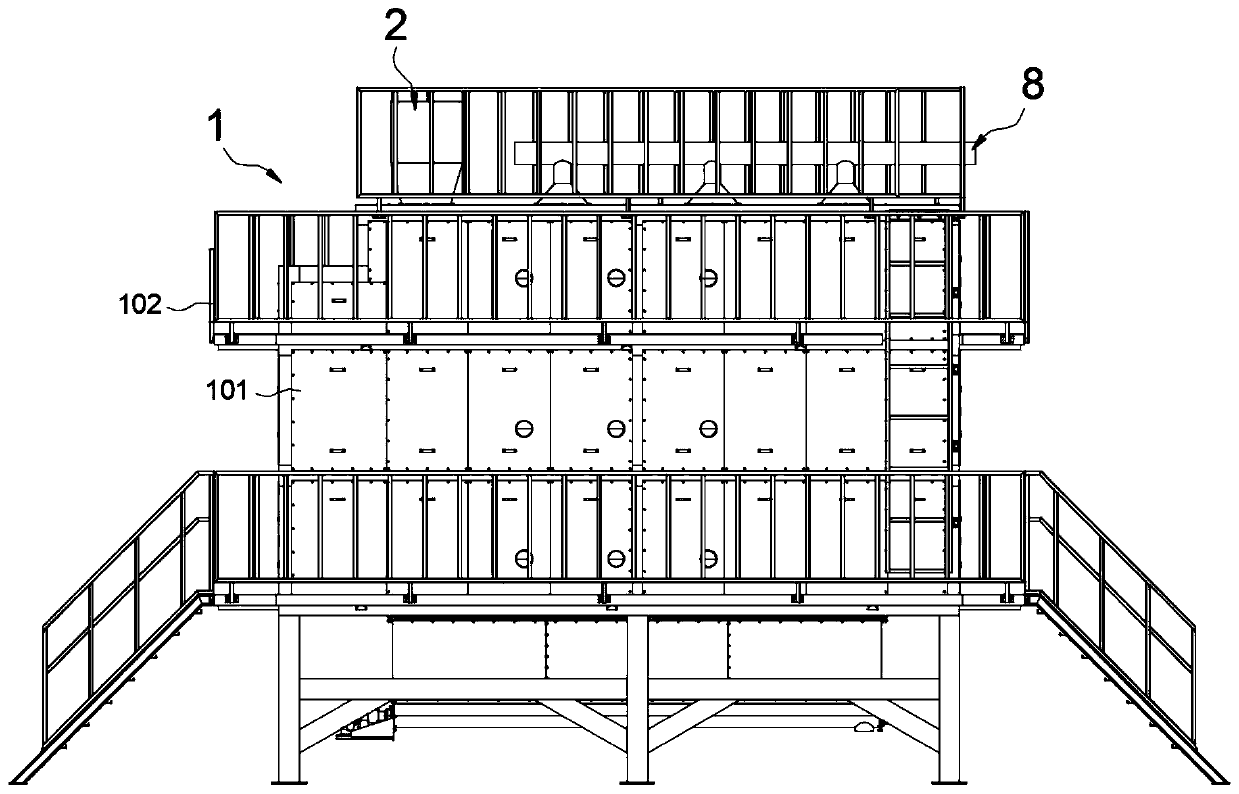

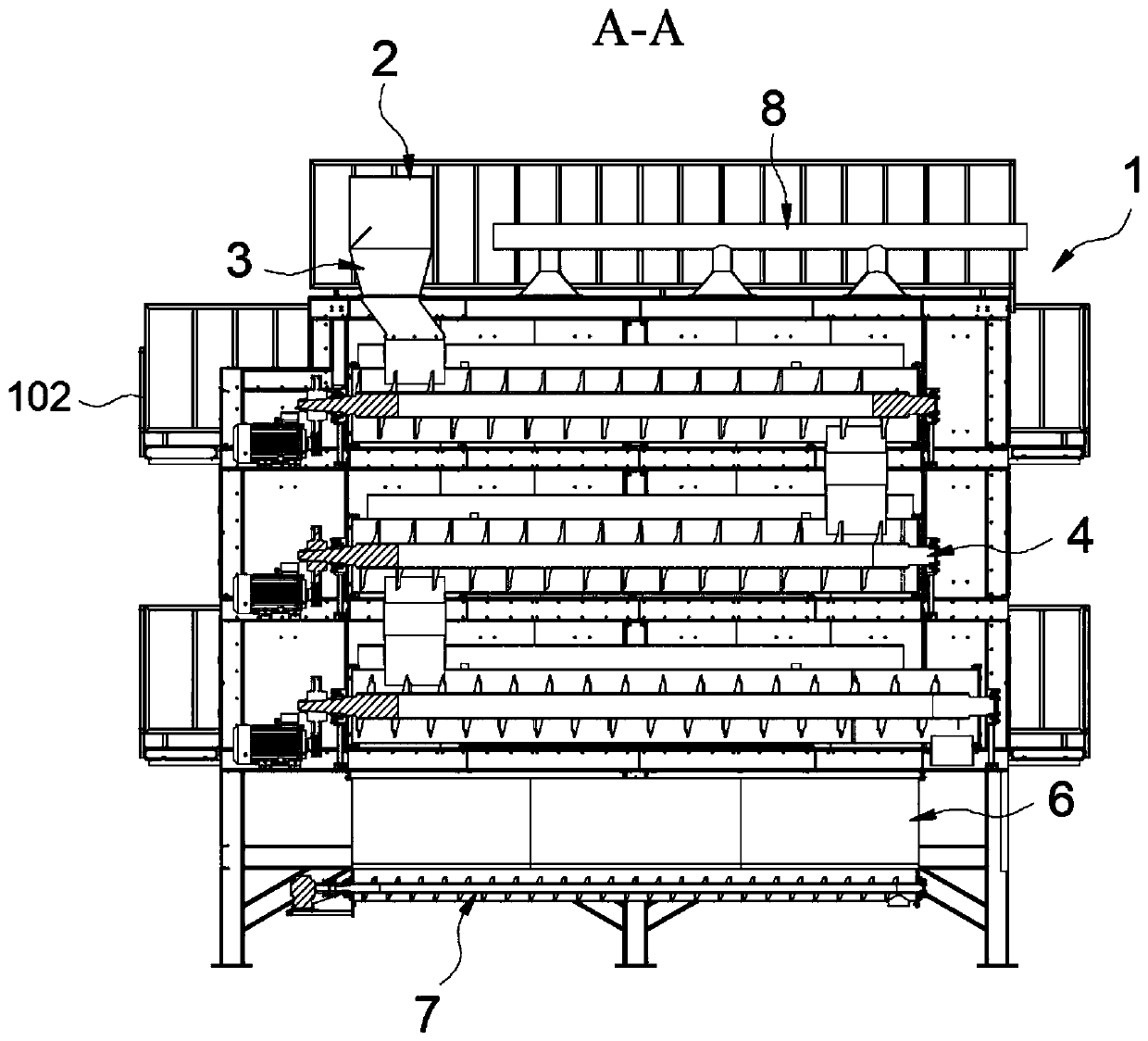

[0043] see Figure 1~3 The drying and cleaning machine in the preferred embodiment of the present invention includes a cabinet 1 in a box structure. A cavity structure is formed inside the cabinet 1 for accommodating various components for drying and cleaning garbage, and its outer periphery is correspondingly provided with The inspection platform 102 is used for inspection and maintenance of each position of the cabinet 1; at the same time, the cabinet 1 in the preferred embodiment is composed of several sealing plates 101 correspondingly assembled to facilitate the disassembly and maintenance of the cabinet 1.

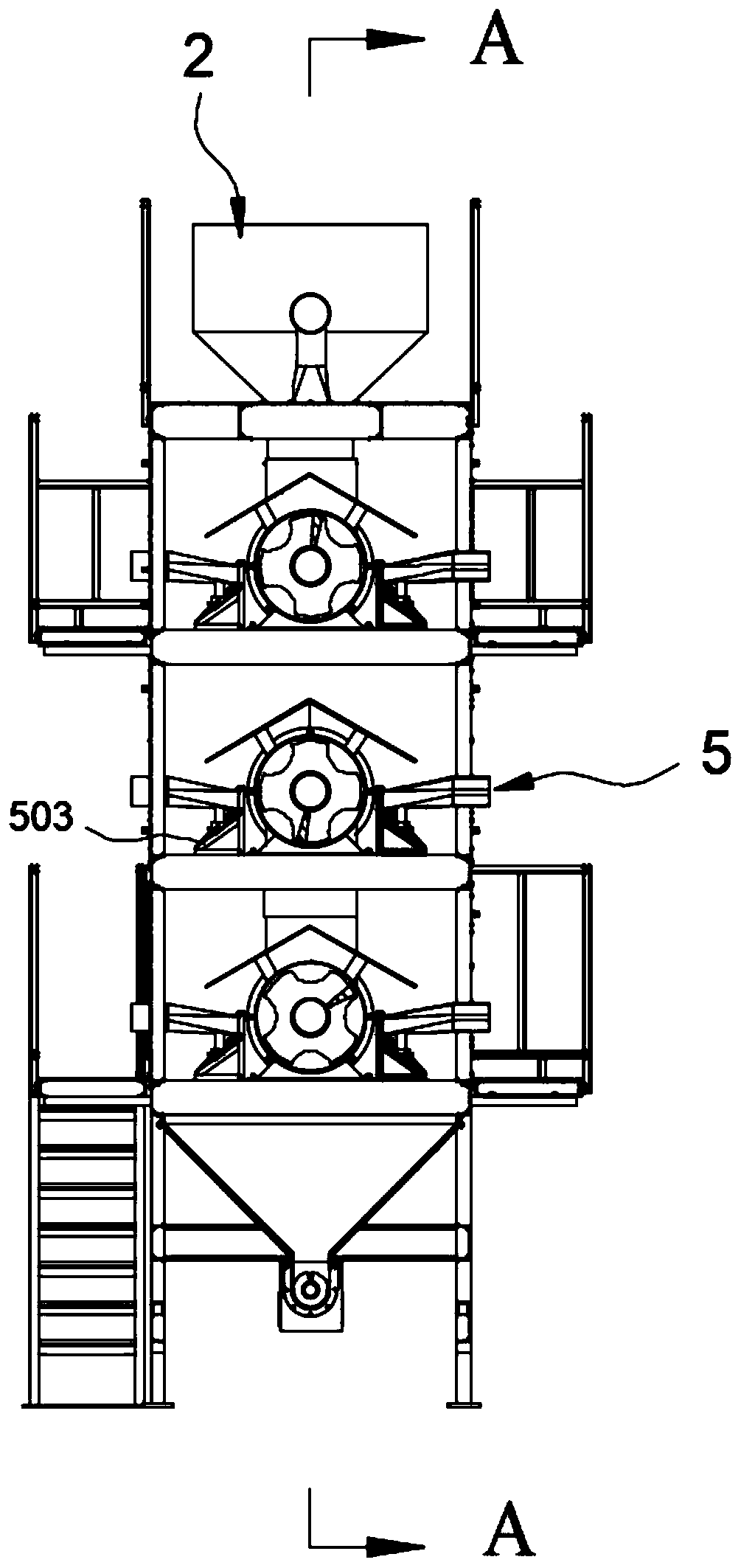

[0044] Specifically, the cabinet 1 in the preferred embodiment is provided with at least one screw conveyor unit 4 for feeding, drying and cleaning of garbage, and correspondingly, a feed hopper 2 is provided corresponding to the feeding port 402 of the screw conveyor unit 4 And guide barrel 3. Wherein, the feed hopper 2 is arranged on the top of the cabinet 1 or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com