Rail locomotive vehicle wheel-rail bearing integrated test device

A rail locomotive and test device technology, applied in the direction of railway vehicle testing, measuring devices, instruments, etc., can solve the problem of inability to effectively realize the radial load of bearings, the inability to effectively simulate the state of steering, and the inability to truly simulate the rail vehicle wheel rail-bearing - Issues such as axle interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

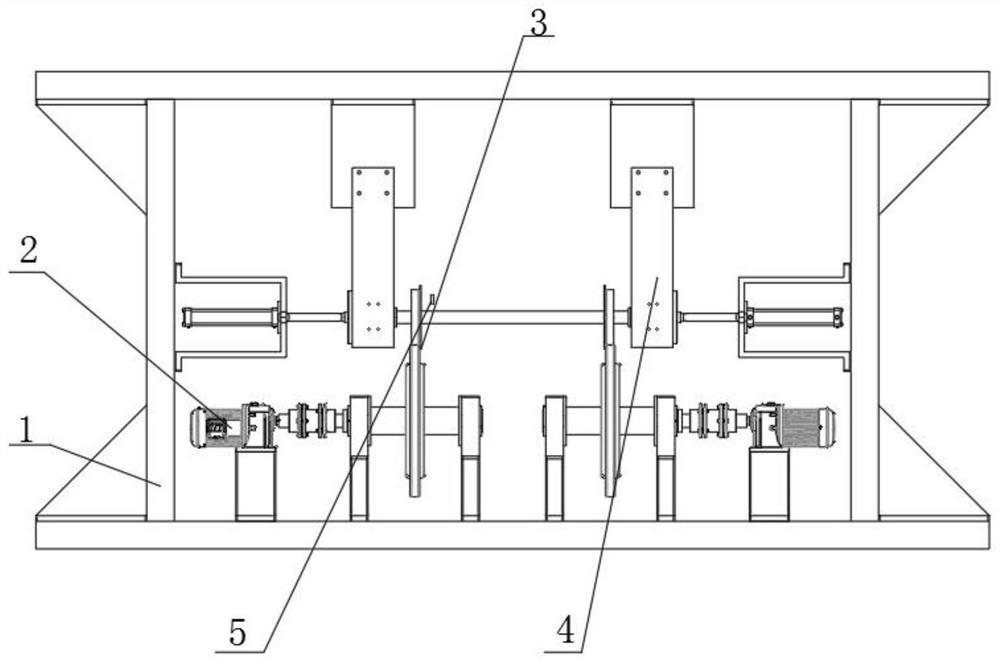

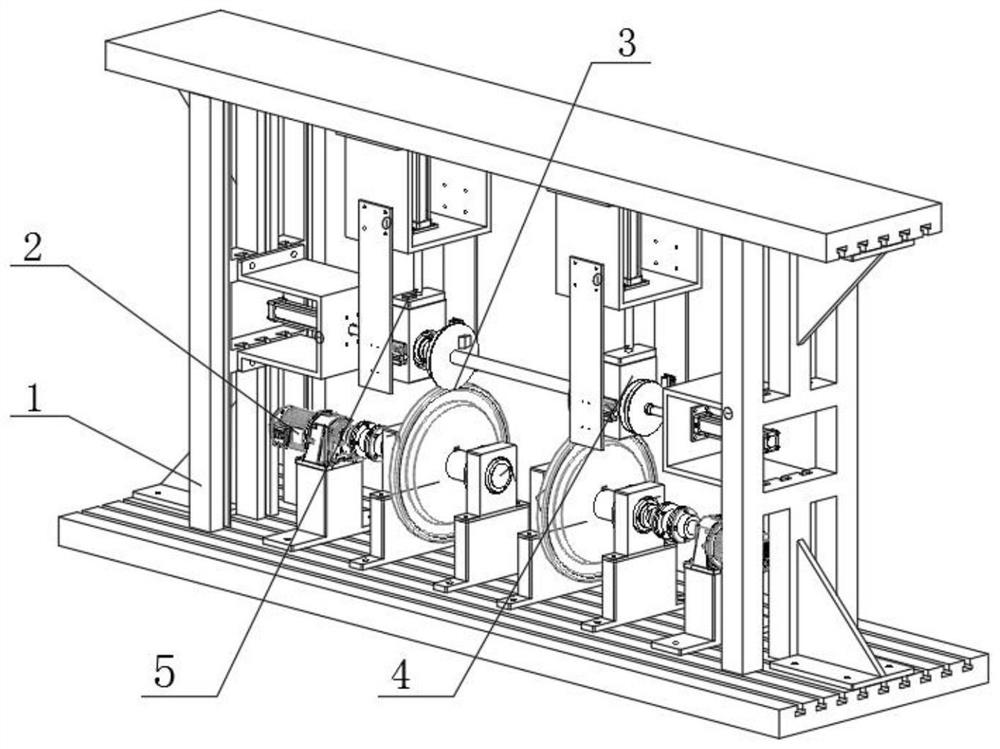

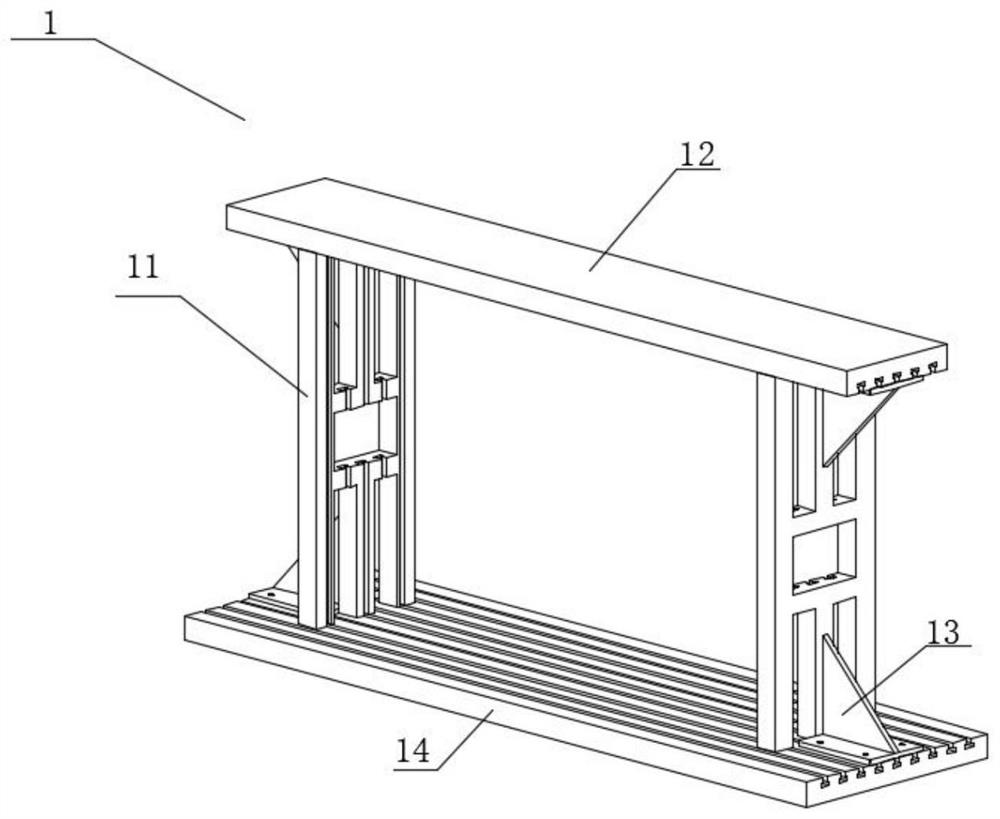

[0044] Combining Figure 1(a) and Figure 1(b), the rail vehicle wheel-rail bearing integrated test device consists of a mechanical support body 1, a drive system 2, a tested wheel-rail-bearing-axle 3, a loading system 4, and a testing system 5 composition. The mechanical support body 1 is a truss structure, which is used to fix and support other systems and components in the test device; the drive system 2 provides rotational power for the entire test device, and is used to drive the wheel-rail-bearing-axle 3 system to rotate, and adopts The bolt connection device is installed on the upper surface of the mechanical support body 1; the tested wheel rail-bearing-axle 3 is the tested object, which is located above the driving system 2 and is in frictional contact with the driving system 2. Based on the mutual friction between the two The test object 3 prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com