Comprehensive test method and device for gas control valve and storage medium

A technology for controlling valves and comprehensive testing, which is used in fluid tightness testing, mechanical valve testing, and machine/structural component testing. Improve production test efficiency and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

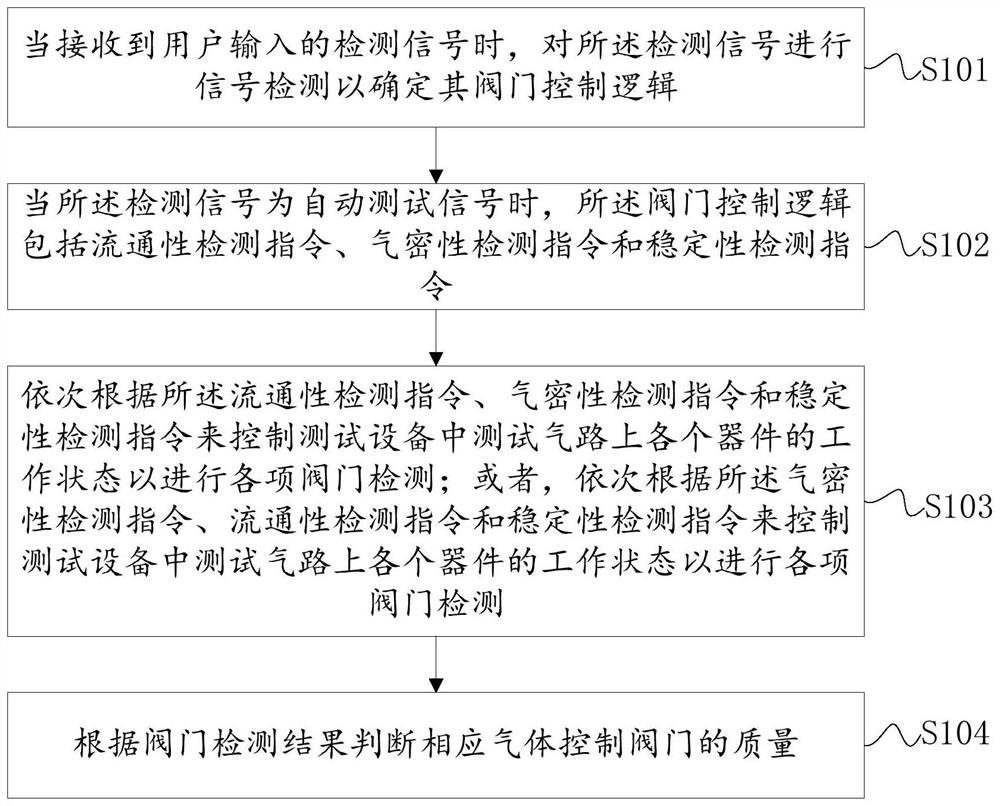

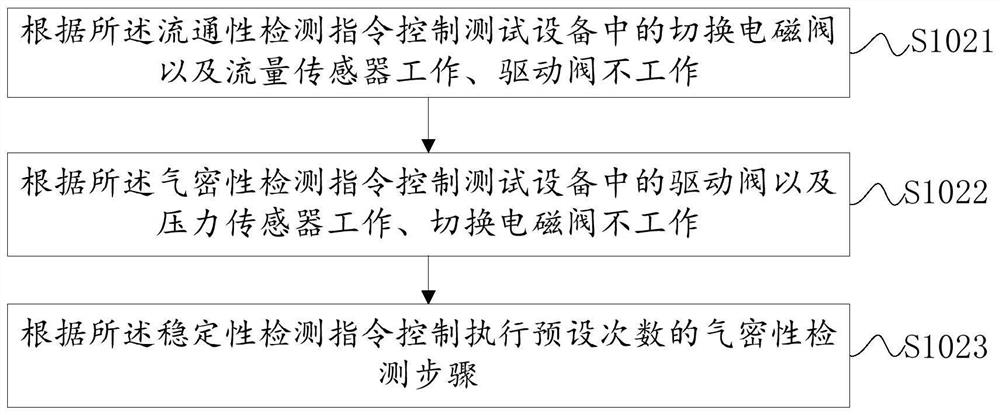

[0053] see figure 1 , figure 1 It is a schematic flowchart of a comprehensive testing method for a gas control valve disclosed in an embodiment of the present invention. Wherein, the execution subject of the method described in the embodiment of the present invention is an execution subject composed of software or / and hardware, and the execution subject can receive relevant information through wired or / and wireless means, and can send certain instructions. Of course, it may also have certain processing functions and storage functions. The execution subject can control multiple devices, such as a remote physical server or cloud server and related software, or a local host or server and related software that perform related operations on devices placed somewhere. In some scenarios, multiple storage devices can also be controlled, and the storage device and the device can be placed in the same place or in a different place. Such as figure 1 As shown, the comprehensive test me...

Embodiment 2

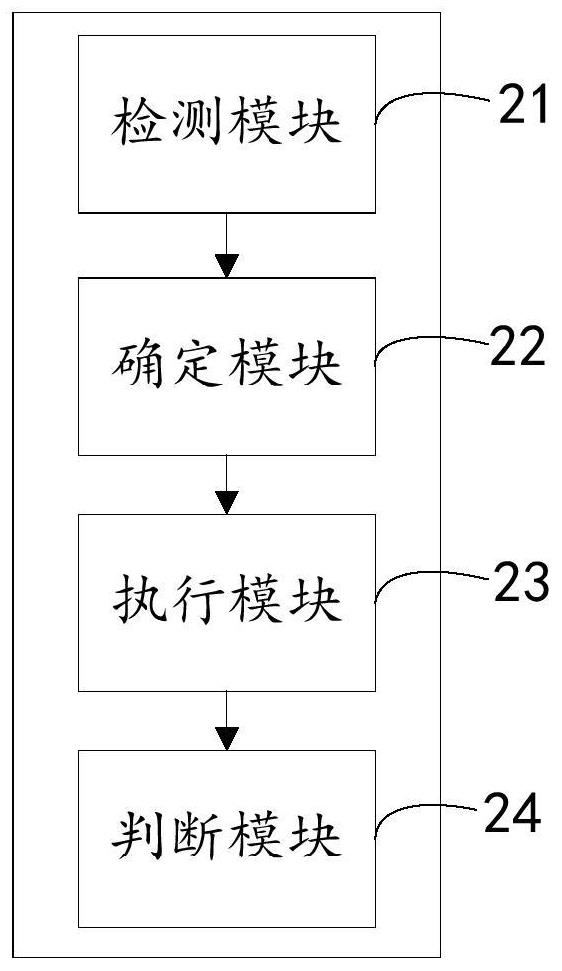

[0074] see image 3 , image 3 It is a structural schematic diagram of a comprehensive testing device for a gas control valve disclosed in an embodiment of the present invention. Such as image 3 As shown, the comprehensive test setup for the gas control valve may include:

[0075] Detection module 21: when receiving a detection signal input by the user, perform signal detection on the detection signal to determine its valve control logic;

[0076] Determination module 22: when the detection signal is an automatic test signal, the valve control logic includes a flowability detection instruction, an air tightness detection instruction and a stability detection instruction;

[0077] Executing module 23: sequentially control the working status of each device on the test gas circuit in the test equipment according to the flowability detection instruction, air tightness detection instruction and stability detection instruction to perform various valve detection; or, sequentially...

Embodiment 3

[0081] Such as Figure 4-Figure 10 As shown, a comprehensive quality testing device for a gas control valve provided by an embodiment of the present invention includes:

[0082] A frame 1, the frame 1 is provided with a workbench 2;

[0083] The first air source assembly 3, the first air source assembly 3 is used to inflate the detection device 4;

[0084] Detecting device 4, described detecting device 4 is arranged on the workbench 2, and described detecting device 4 comprises detecting body 41, pressure sensor 43, switching solenoid valve 44 and flow sensor 45; Described detecting body 41 is provided with test channel, in An air control valve installation position and a switching solenoid valve 44 are sequentially arranged on the test channel, and the air control valve installation position is used to install the air control valve 42 to be tested;

[0085] The air control valve 42 to be tested and the switching solenoid valve 44 are both used to control the on-off of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com