Wet garbage solid-liquid separation device

A technology of solid-liquid separation and garbage, which is applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of inadequate dry and wet classification, low efficiency of wet garbage classification, and difficult screening, etc., and achieve garbage classification Easy, good punchability, and the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

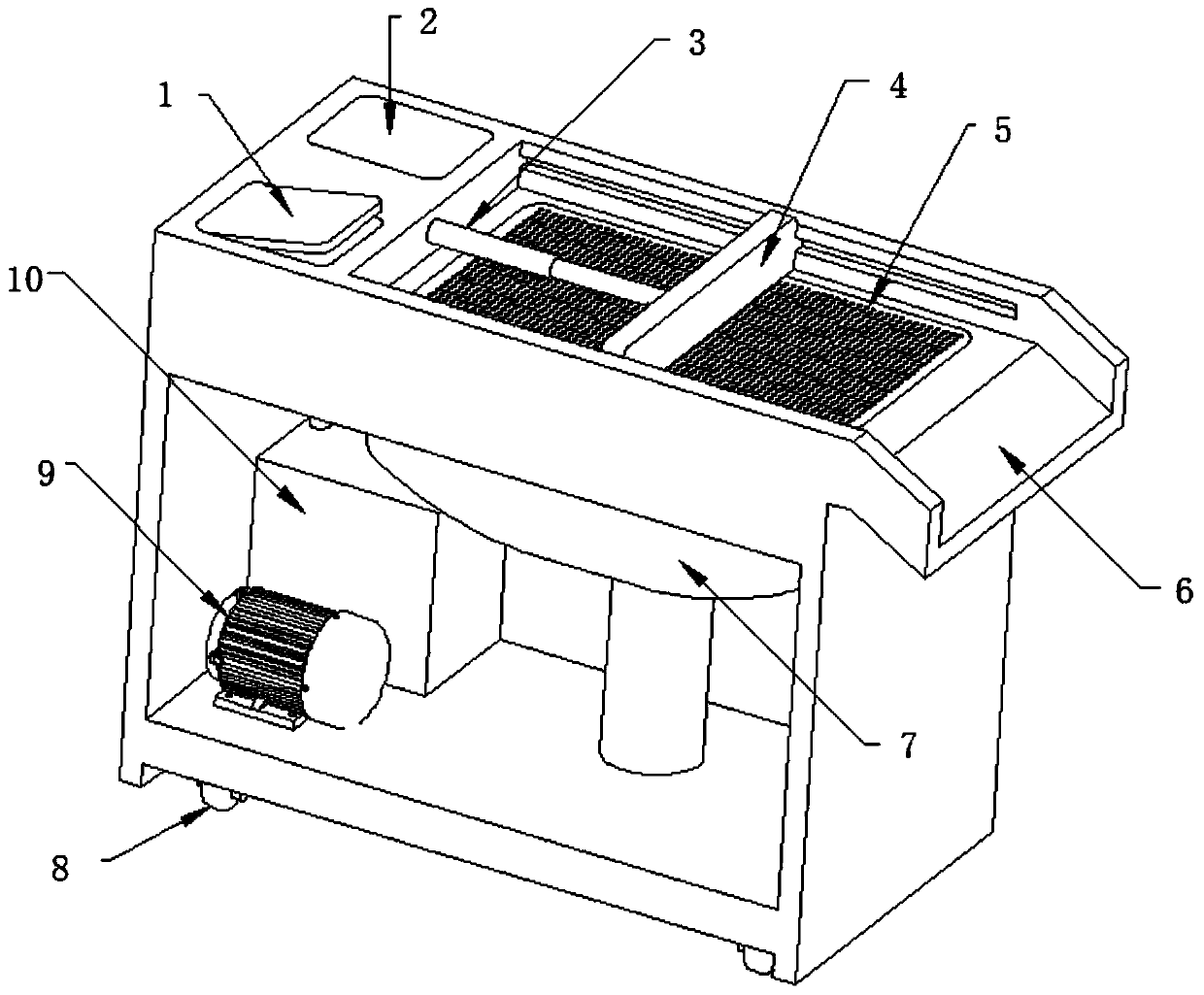

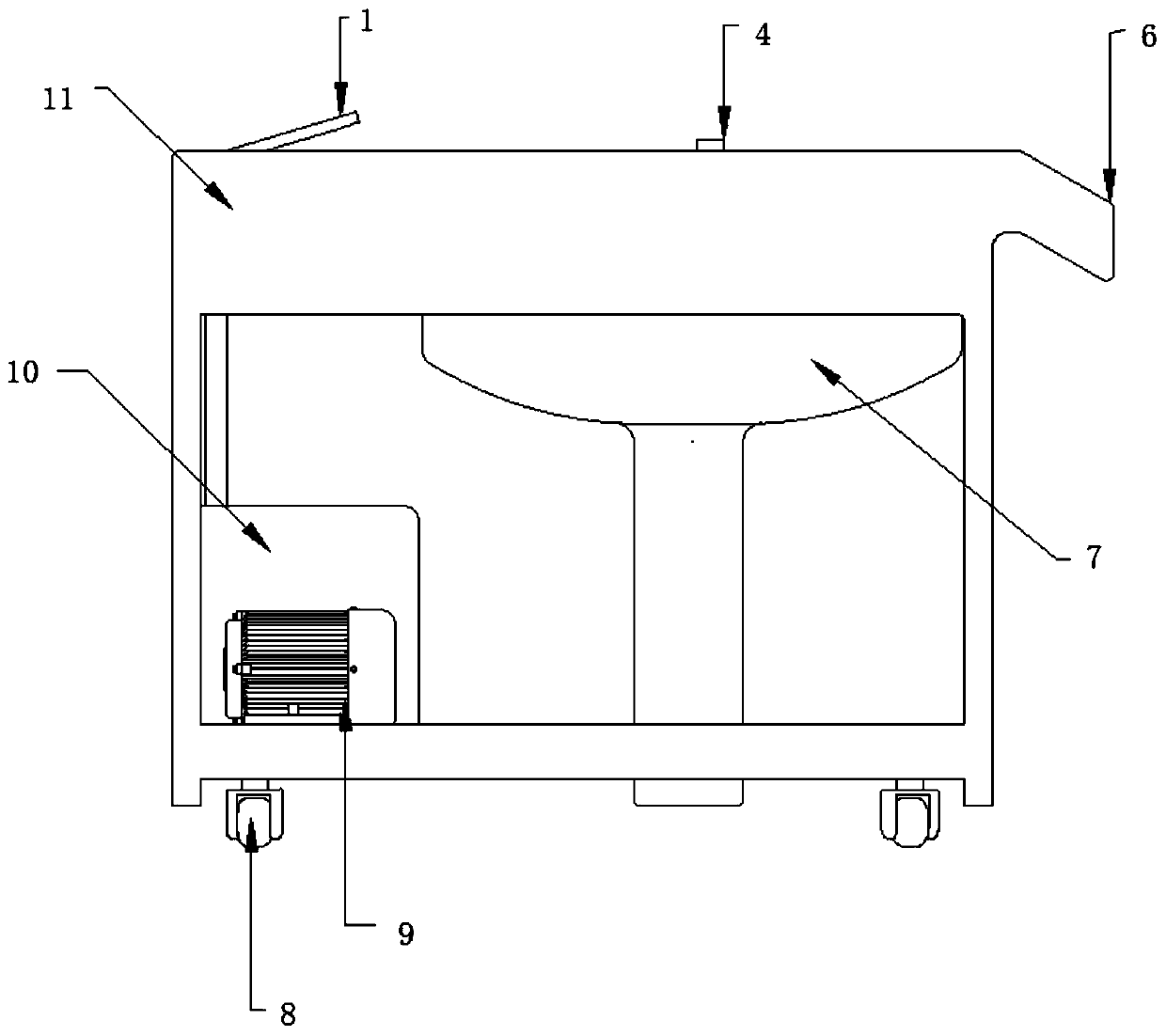

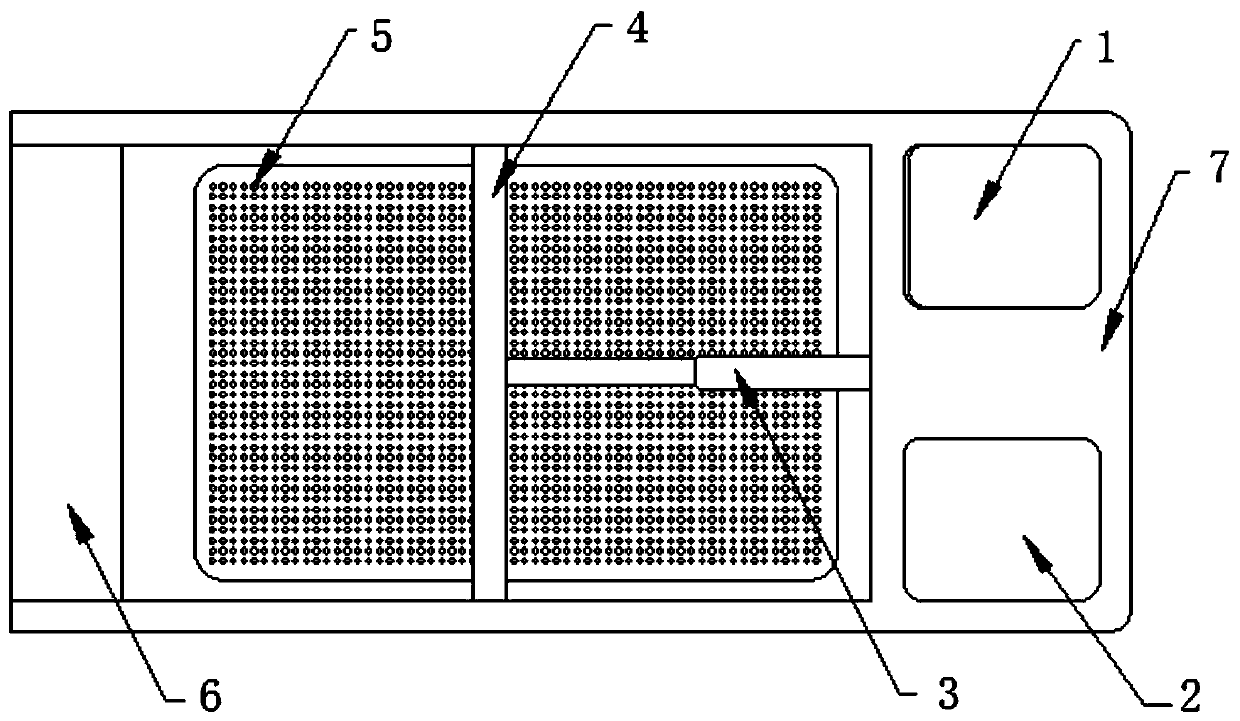

[0031] Such as Figure 1~3 As shown, a wet garbage solid-liquid separation device includes a box body 11 and a percolation mechanism and an electric push mechanism arranged on the box body 11. The percolation mechanism includes a filter plate 5 and a sink 7 under the filter plate 5. The pushing mechanism includes a push rod and a baffle 4 connected to each other. After the wet garbage is dumped on the filter plate 5, the liquid in the wet garbage falls into the sink 7, and the push rod pushes the baffle 4 to move horizontally to separate the solid and liquid. The garbage is pushed away from the filter plate 5.

[0032] The bottom of the sink 7 has a water pipe, and the bottom of the water pipe is an odor-proof floor drain.

[0033] The push rod is a three-section hydraulic push rod 3. After the solid-liquid separation of the wet waste is completed, the wet waste can be directly pushed into the designated position, which effectively improves the sorting efficiency and shares the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com