Anti-radiation automatic flaw-inspecting machine

A flaw detector and radiation protection technology, applied in the field of radiation protection automatic flaw detectors, can solve the problems of carcinogenicity, endangering people's physical and mental health, etc., and achieve the effects of preventing radiation exposure, reducing personnel costs, and preventing personnel from being exposed to radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

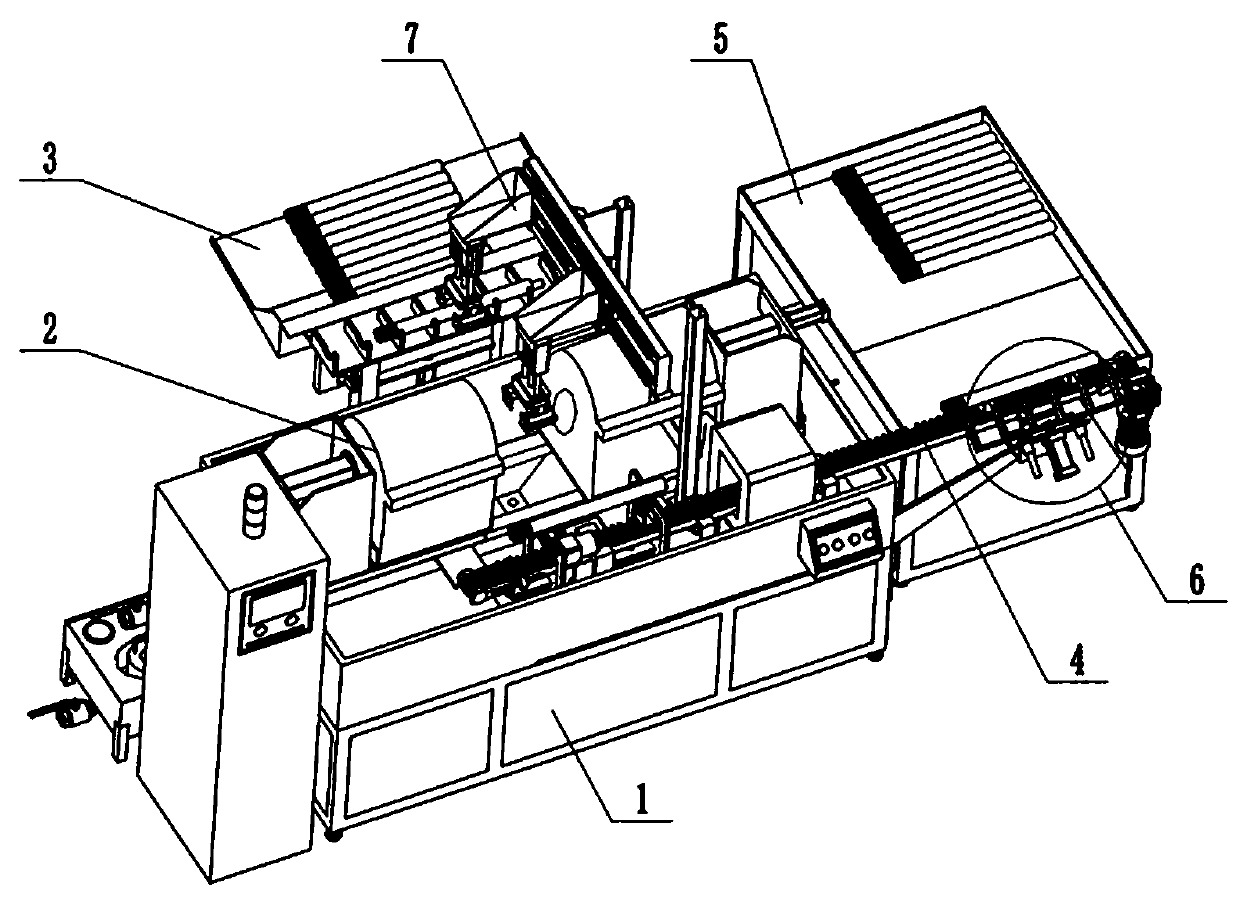

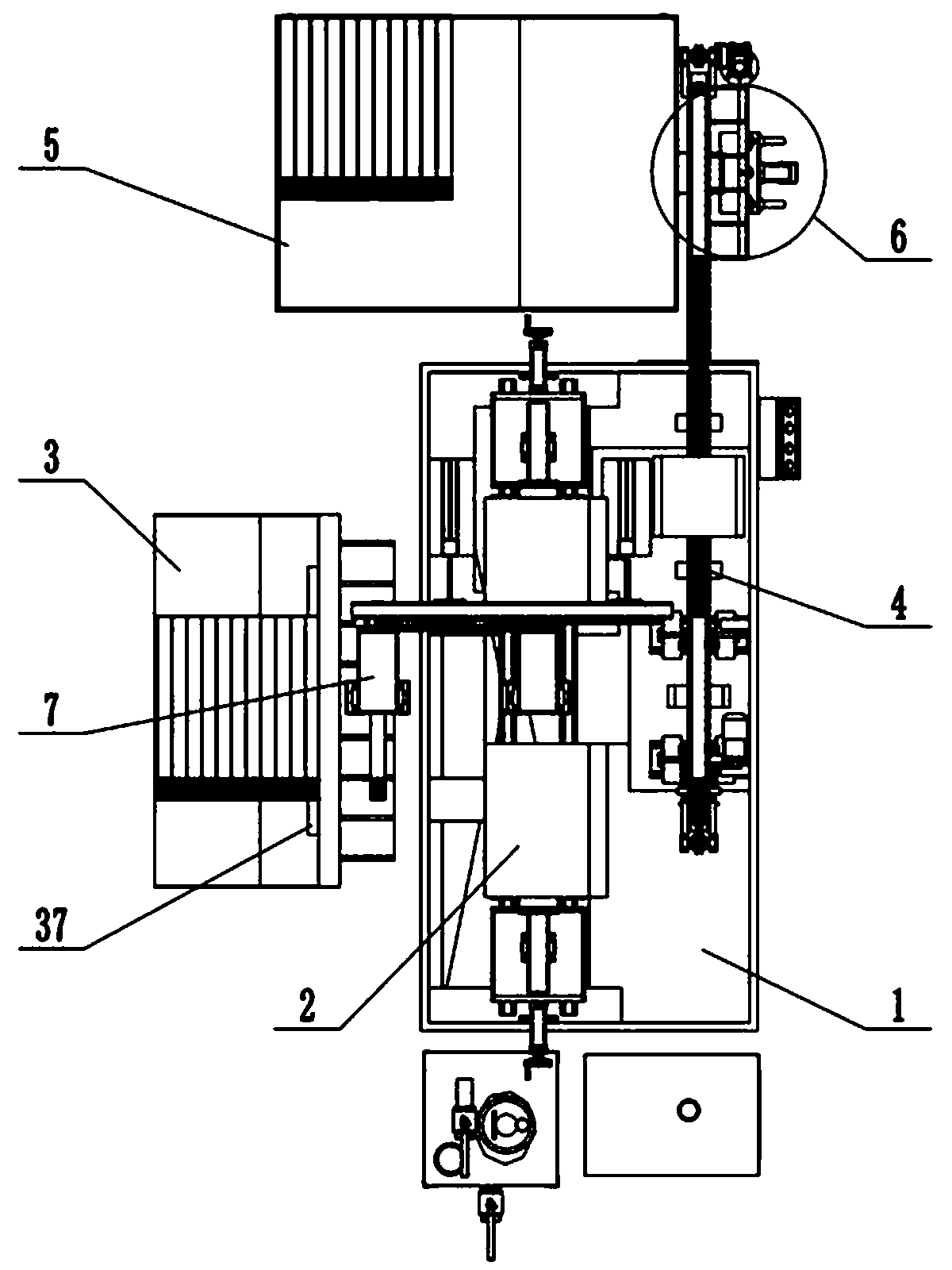

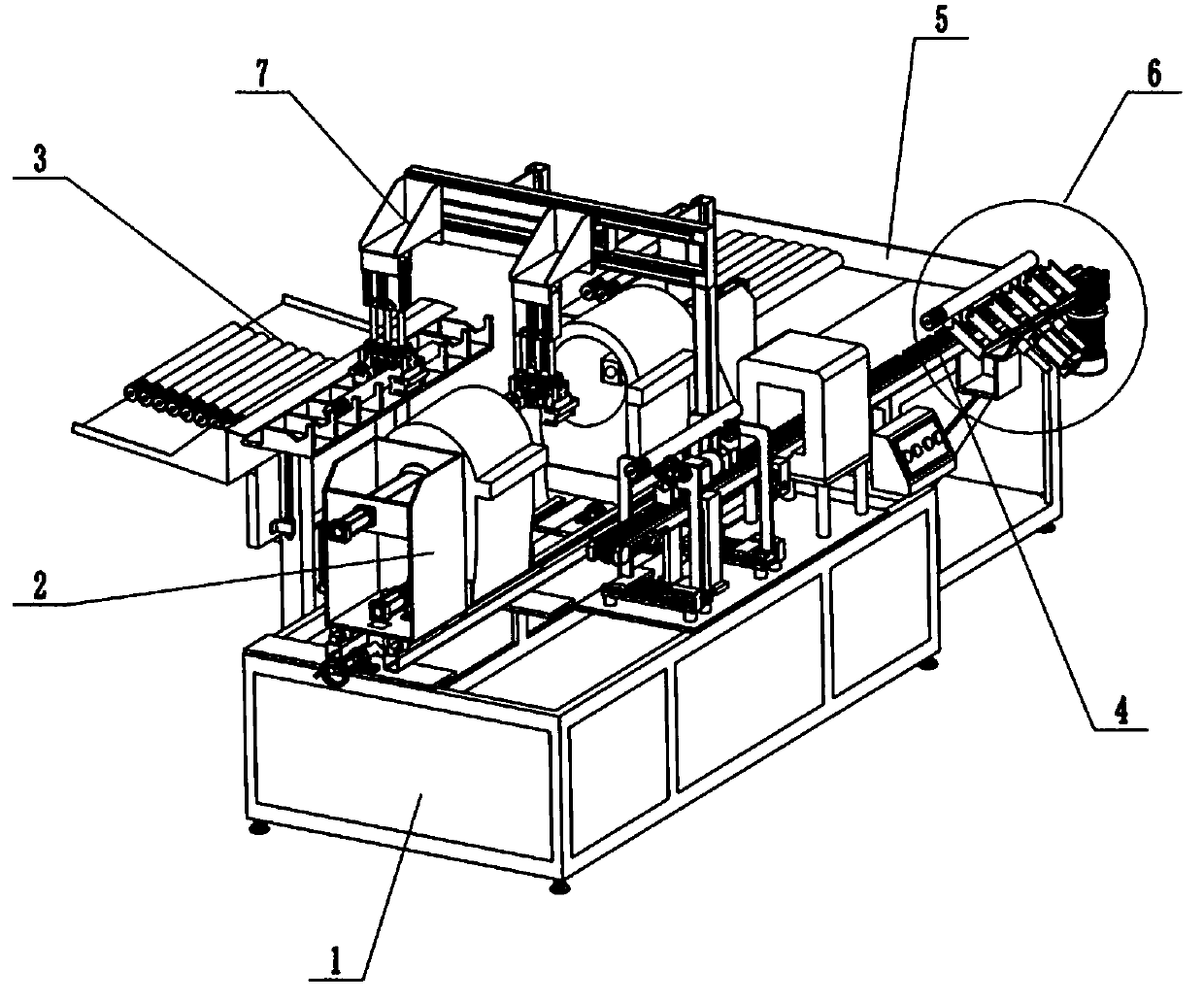

[0031] refer to figure 1 , figure 2 and image 3 , a radiation-proof automatic flaw detection machine, comprising a detection platform 1, a flaw detection device 2, a feeding platform 3, a conveying device 4, a discharging platform 5, a discharging device 6 and a manipulator clamping device 7; the feeding platform 3 and The unloading platform 5 is respectively located on both sides of the detection platform 1; the flaw detection device 2 is arranged above the detection platform 1; the transmission device 4 is arranged between the flaw detection device 2 and the unloading platform 5; the manipulator clamping device 7 is arranged between the feeding platform 3 , the flaw detection device 2 and the conveying device 4 ;

[0032] refer to Image 6 , the flaw detection device 2 includes a guide rail 21, a first flaw detection chamber 22, a second flaw detection chamber 23, a clamping cylinder 24, a flaw detection chamber pushing cylinder 25, a clamping device 26, an adjustment s...

Embodiment 2

[0049] The specific difference between embodiment 2 and embodiment 1 is:

[0050] Further, one end of the conveyor belt 41 located at the detection platform 1 is also provided with a first deck 44 and a second deck 45; the first deck 44 and the second deck 45 are symmetrically arranged on both sides of the conveyor belt 41, Its upper end is provided with runner 48, and its lower end slides and inserts on the card seat guide rail 46 that is arranged on the detection platform 1, and is provided with card seat between the bottom end of first card seat 44 and second card seat 45 Cylinder 47.

[0051] Either wheel 48 at the upper end of the first deck 44 and the second deck 45 is provided with a wheel 48 driving motor.

[0052] The specific implementation process:

[0053] After the flaw detection is completed, the pipe is first moved to the runner 48 by the gripping device 7 of the manipulator, and the motor is driven by the runner to realize the rotation of the runner 48 and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com