Three-spindle numerical control machine tool

A technology of CNC machine tools and spindle motors, applied in the field of machine tools, can solve problems such as inability to link, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

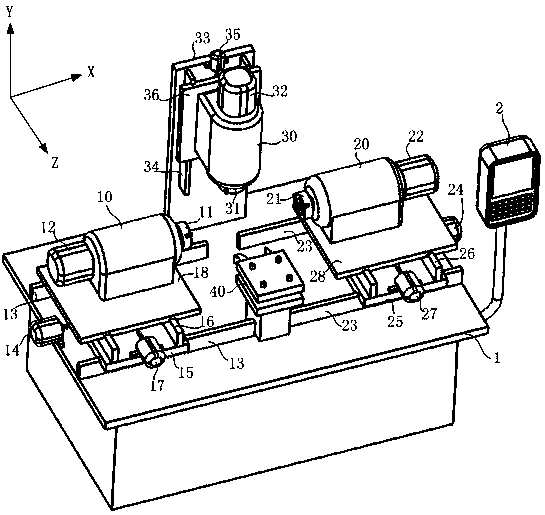

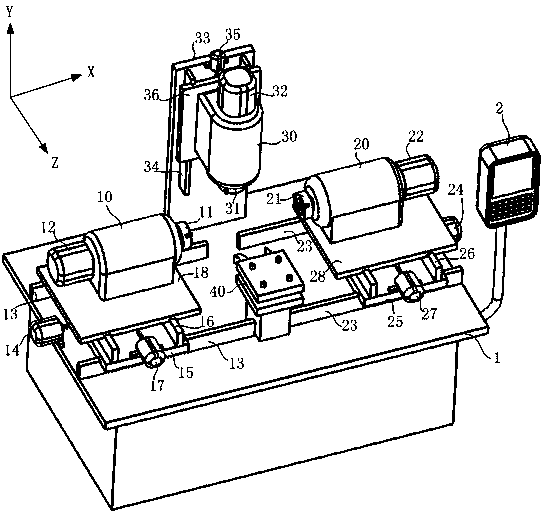

[0018] Embodiment 1, as shown in the figure, a three-spindle CNC machine tool includes a machine platform 1 and a numerical control system 2, and a first spindle box 10 capable of moving in the X and Z directions is installed on the left side of the machine platform 1 , the second headstock 20 capable of moving in the X and Z directions is installed on the right side of the machine platform 1, and the third headstock 30 capable of moving in the Y direction is installed on the rear side of the middle part of the machine platform 1 A tool rest 40 is fixed on the front side of the middle part of the machine table 1, and the first main shaft, the second main shaft and the third main shaft are respectively pivoted in the first main headstock 10, the second main headstock 20 and the third main headstock 30. Main shaft, the right end of the first main shaft extends out of the first headstock 10 and connects to the first holder 11, and the left end of the second main shaft extends out ...

Embodiment 2

[0036] Embodiment 2, other is the same as Embodiment 1, the difference is that the first spindle motor 12 is located on one side of the first spindle box 10, and the motor shaft of the first spindle motor 12 is fixedly connected to the driving synchronous pulley , the first main shaft is fixedly connected to the driven synchronous pulley, and a synchronous belt is set on the driving synchronous pulley and the driven synchronous pulley; the second main shaft motor 22 is located on one side of the second main shaft box 20, so The motor shaft of the second main shaft motor 22 is fixedly connected to the driving synchronous pulley, the first main shaft is fixed to the driven synchronous pulley, and a synchronous belt is sleeved on the driving synchronous pulley and the driven synchronous pulley; the third main shaft The motor 32 is located on one side of the third spindle box 30, the motor shaft of the third spindle motor 32 is fixed to the driving synchronous pulley, the first mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com