Adjustable board cutting device

An adjustable board feeding device technology, applied in metal processing and other directions, can solve the problems of incomplete cutting and separation of PCB boards, increased product defect rate, and blunt shearing head, so as to improve the competitiveness of enterprises and improve production efficiency And the effect of production yield and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

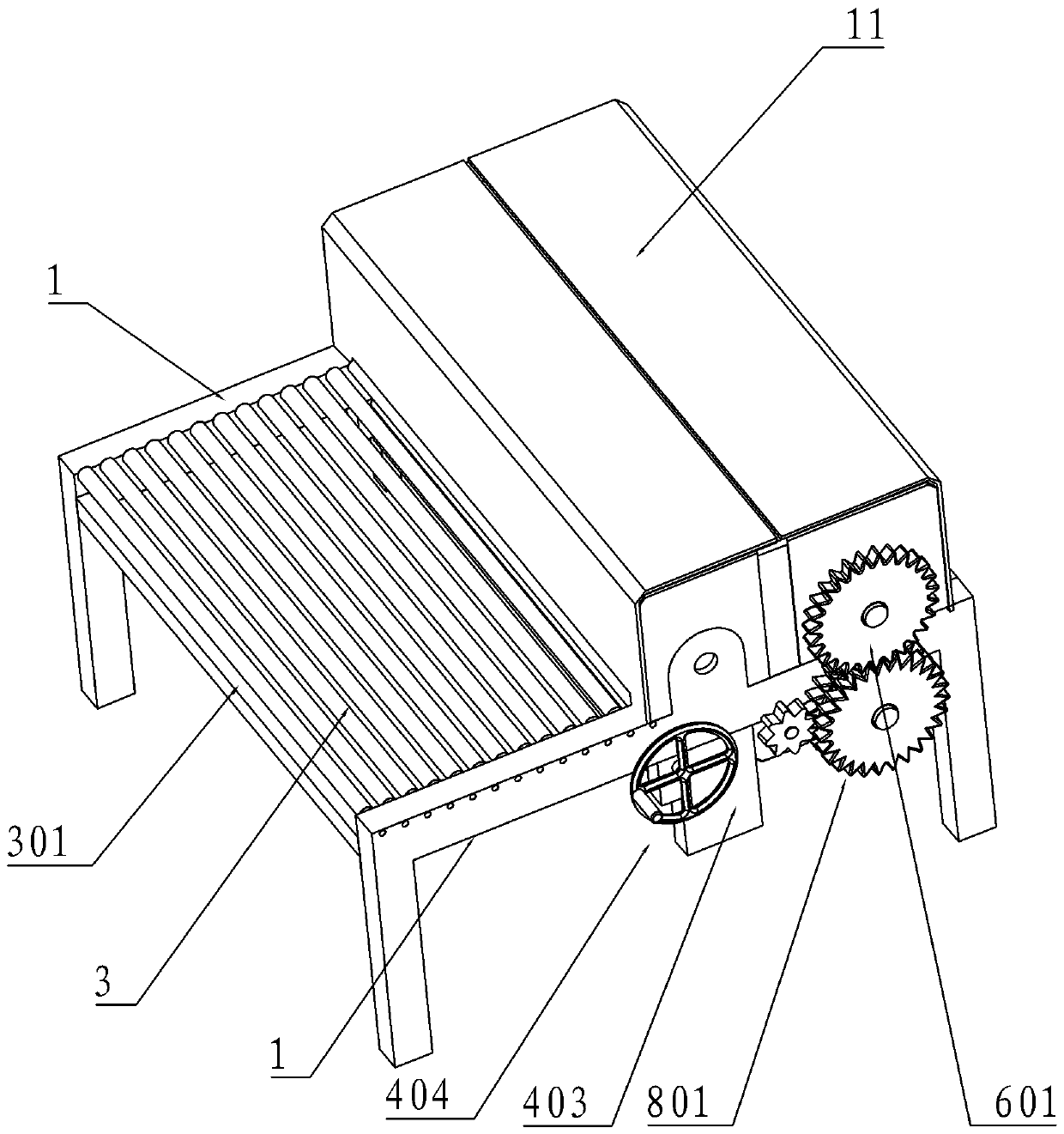

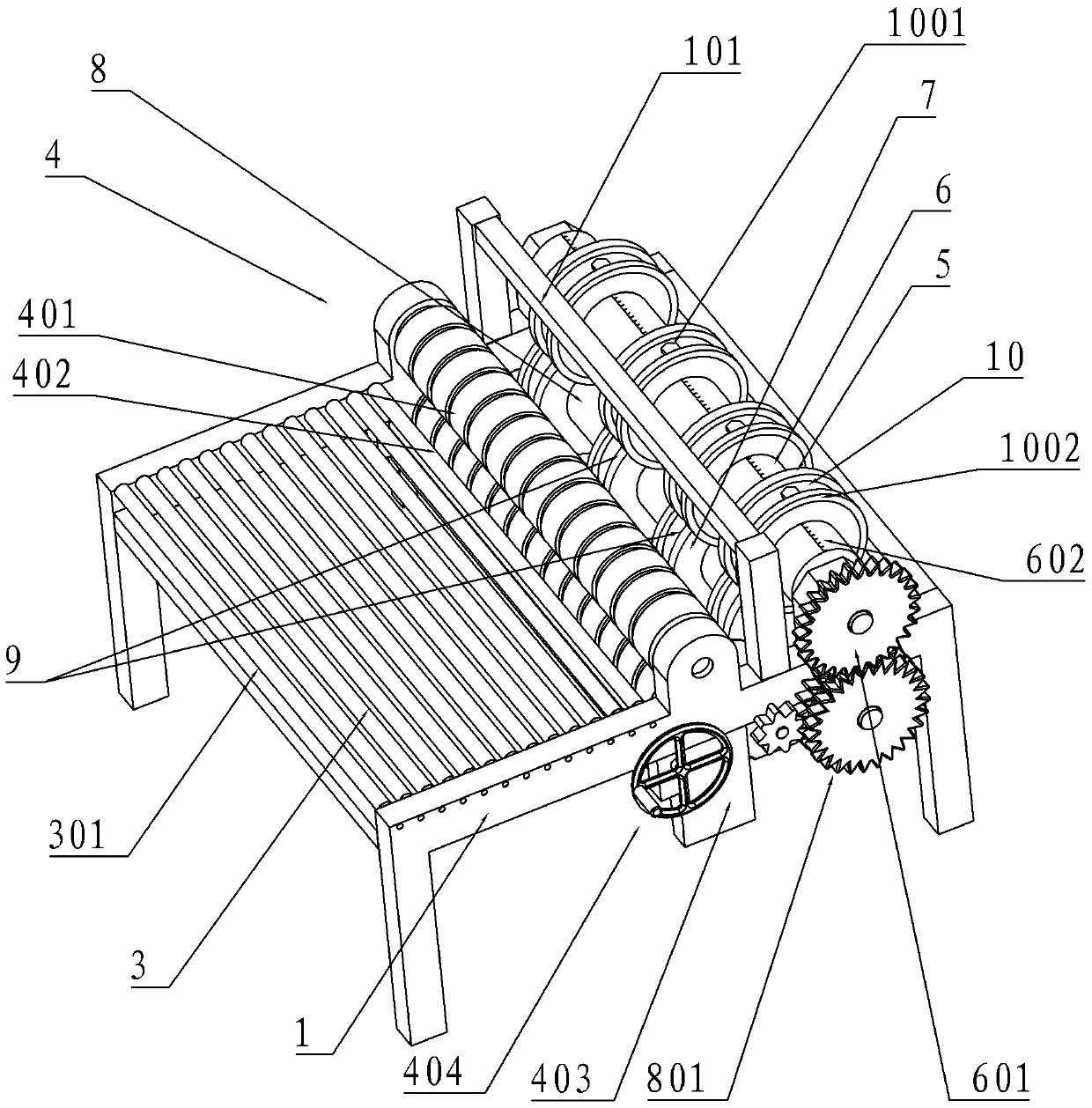

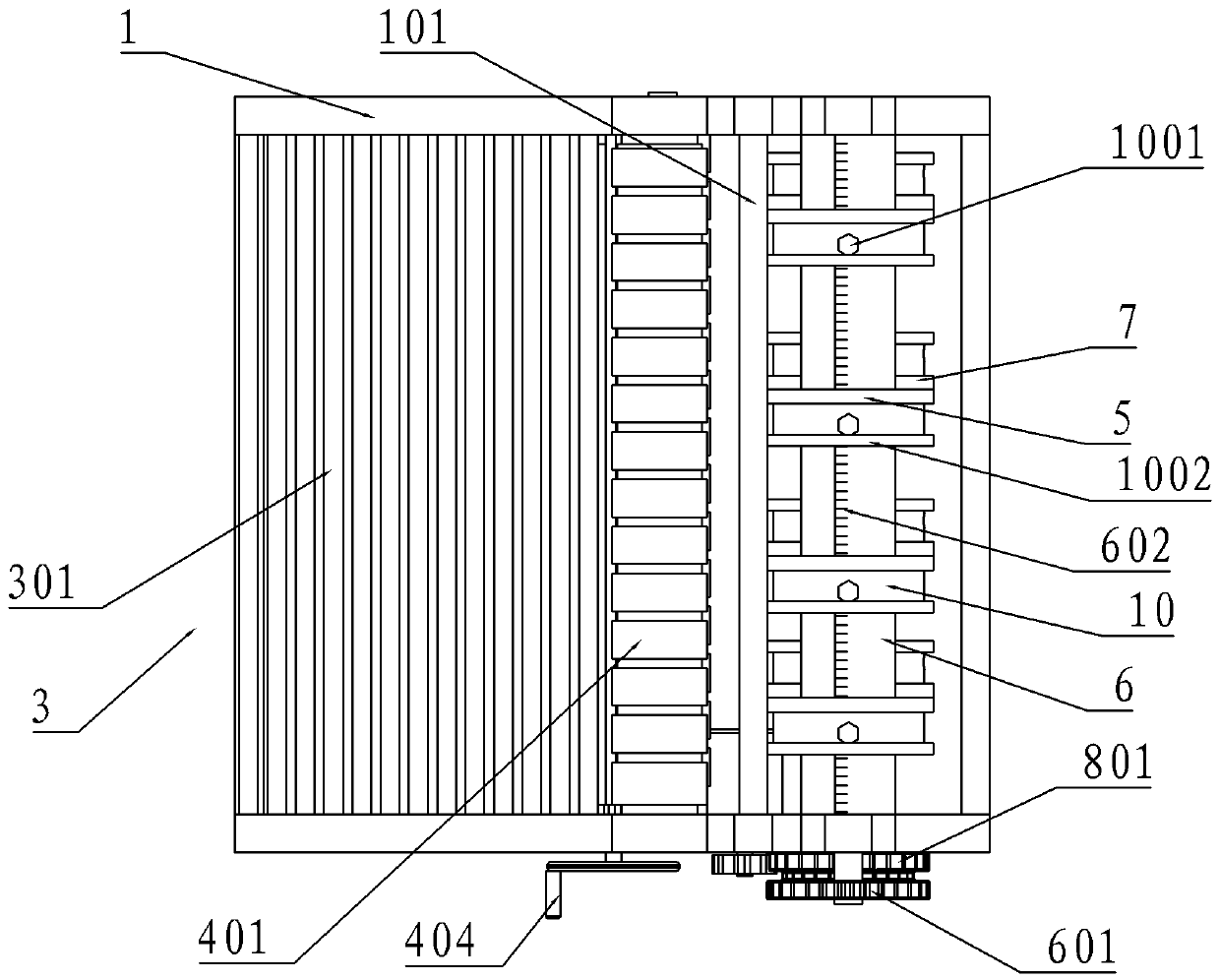

[0023] Such as Figure 1 to Figure 4 As shown, the adjustable plate cutting device includes a machine base 1 and a plate feeding device 3, a platen alignment device 4 and a rolling shear device that are sequentially arranged on the machine base 1 from the feed end to the discharge end. The rolling shear device consists of The sliding suit has an upper shaft 6 with multiple upper hobs 5 and the sliding suit has a lower shaft 8 with a plurality of lower hobs 7. Each upper hob 5 and the lower hob 7 are staggered, and the staggered joints are used to form It is used to cut the notch 9 of the PCB board. When cutting the PCB board, the PCB board is sequentially adjusted from the feeding end through the board feeding device 3 and the pressing plate alignment device 4, and then sent to the rolling shearing device for cutting; The upper hob 5 and the lower hob 7 that are interlaced with the lower rotating shaft 8 can cut PCB boards of different sizes by adjusting the position of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com