Wooden table leg automatic rotary drilling equipment

A technology of automatic rotating and punching equipment, applied in wood processing appliances, stationary drilling machines, bark area / debris / dust / waste removal and other directions, can solve the problems of inconvenient collection of debris, dangerous processing, time-consuming and laborious, etc. Achieve the effect of saving manpower, maintaining accuracy, and avoiding industrial accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

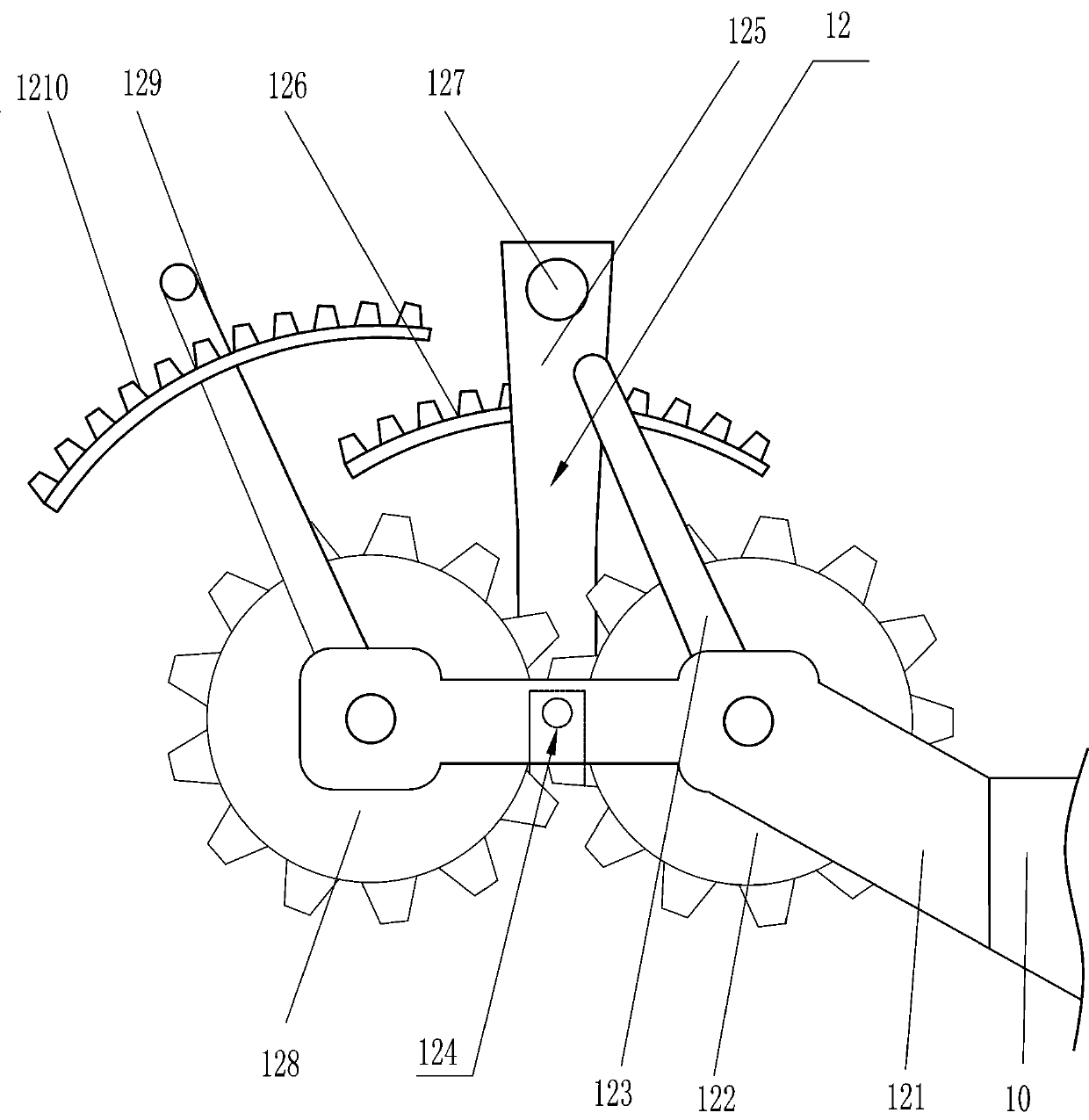

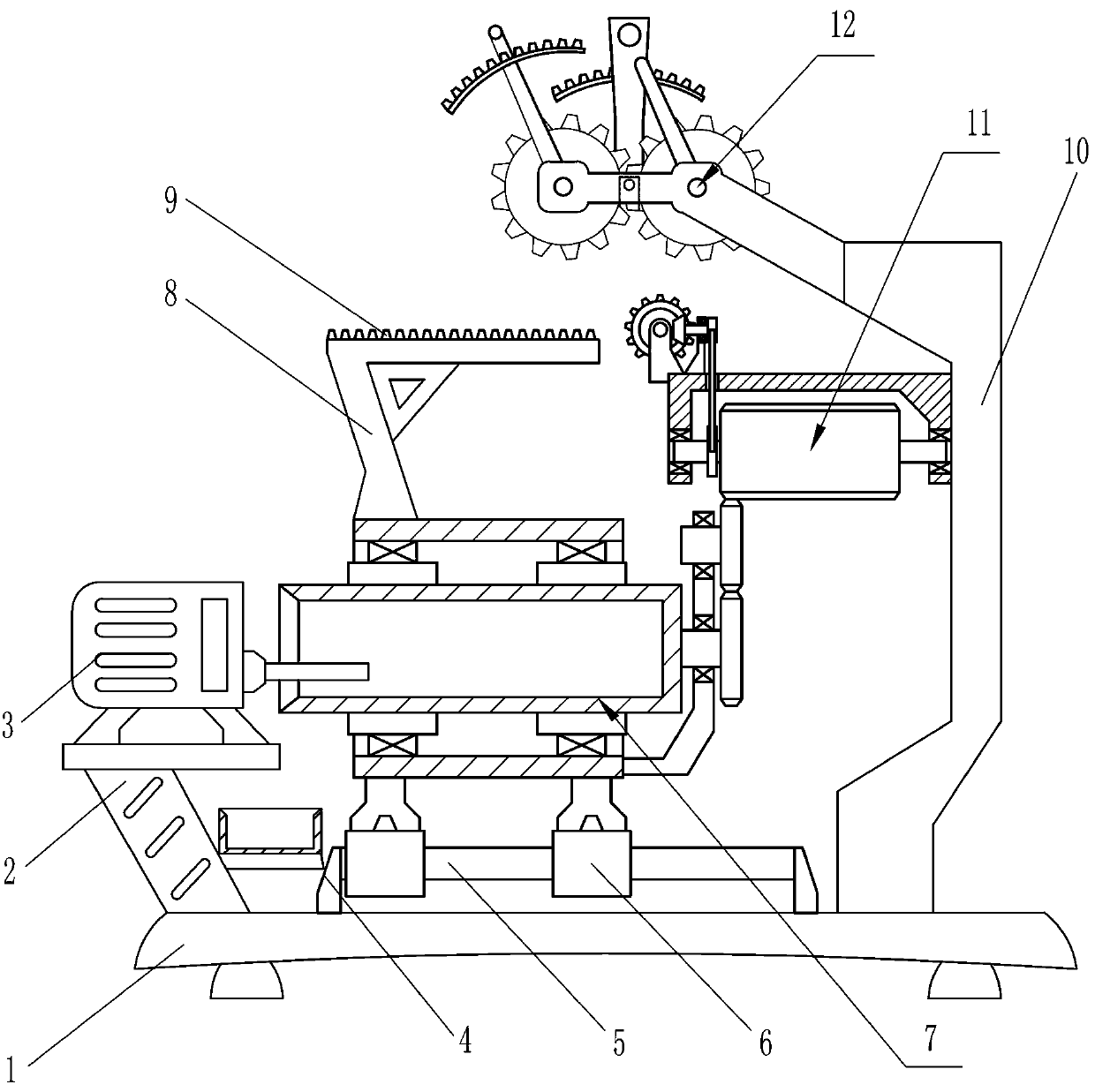

[0022] An automatic rotary punching device for wooden table legs, such as figure 1 As shown, it includes a mounting seat 1, a first support plate 2, a drilling machine 3, a support 4, a guide rail 5, a guide sleeve 6, a rolling device 7, a first bracket 8, a spur rack 9, a second bracket 10, The rotating device 11 and the power device 12 are specifically:

[0023] The left side of the upper part of the mounting seat 1 is provided with a first support plate 2, the upper part of the first support plate 2 is equipped with a drilling machine 3, the middle of the upper part of the mounting seat 1 is symmetrically provided with a support 4, and a guide rail 5 is provided between the support 4, and the guide rail There are two guide sleeves 6 in the sliding type on 5, the upper part of the guide sleeve 6 is provided with a rolling device 7, the upper part of the rolling device 7 is provided with a first bracket 8, the upper part of the first bracket 8 is provided with a straight rack...

Embodiment 2

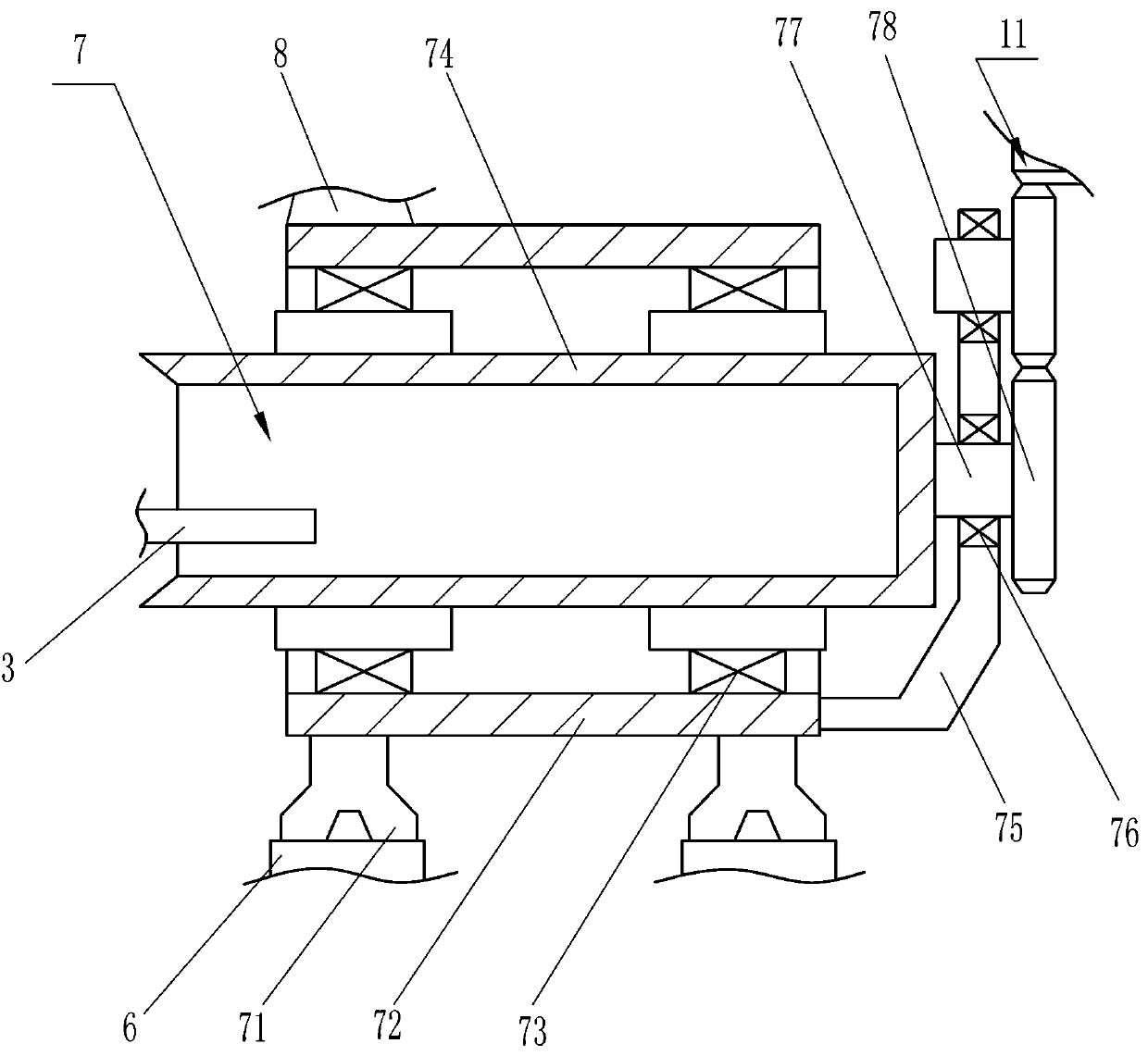

[0026] On the basis of Example 1, such as Figure 2-6 As shown, the rolling device 7 includes a support block 71, an outer frame body 72, a first bearing seat 73, a raw material placement box 74, a connecting frame 75, a second bearing seat 76, a first rotating rod 77 and a first gear 78, specifically for:

[0027] The upper part of the guide sleeve 6 is provided with a supporting block 71, the upper part of the supporting block 71 is provided with an outer frame body 72, the left side of the upper part of the outer frame body 72 is connected with the first bracket 8, and the inner side of the outer frame body 72 is symmetrically equipped with a first bearing seat 73, The first bearing seat 73 is provided with a raw material placement box 74, and the right side of the outer frame body 72 bottom is provided with a connecting frame 75, and two groups of second bearing blocks 76 are installed vertically on the upper part of the right side of the connecting frame 75, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com