A method for preparing a low-density heat-resistant composite material rotary body

A composite material and low-density technology, which is applied in the direction of weight reduction, can solve the problems of prefabricated body folds, parts defects, and increase the cost of parts, so as to avoid poor efficiency, prevent wrinkles or deformation, and save cleaning time.

Active Publication Date: 2022-05-31

EAST CHINA UNIV OF SCI & TECH

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The preforms of resin-based heat-resistant materials are mostly stitched, three-dimensional braided, and needle-punched structures, which generally have low density and are sensitive to pressure. Using conventional RTM methods, the preforms often have wrinkles and deformations. If the defects of the parts exceed a certain area, the parts will be scrapped, which will greatly reduce the success rate of the parts and increase the cost of the parts.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0057] This low-density heat-resistant composite material of revolution includes a fiber preform and a thermosetting resin, and the fiber preform

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

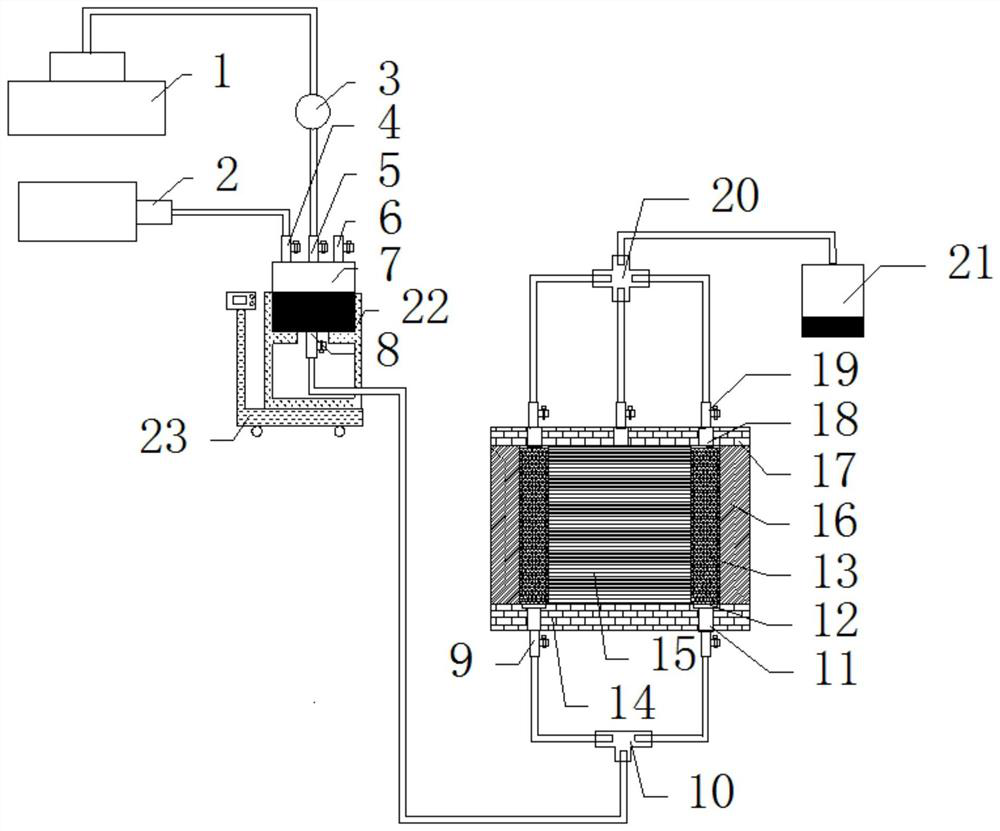

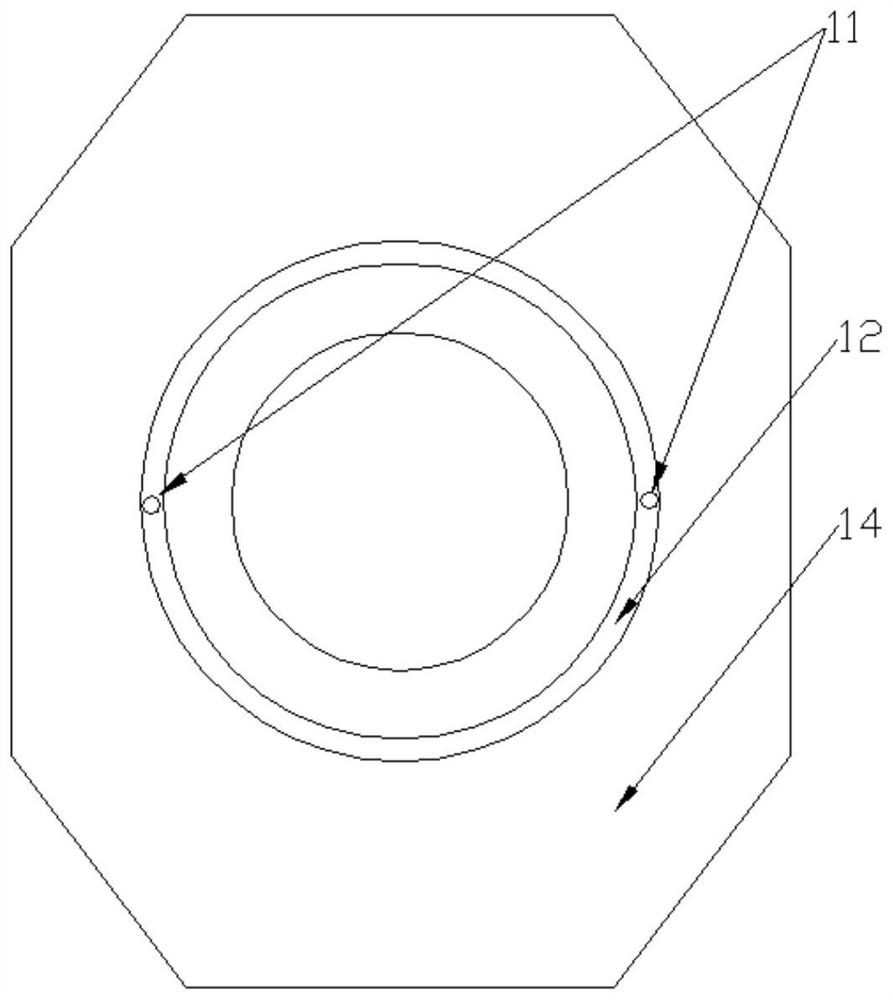

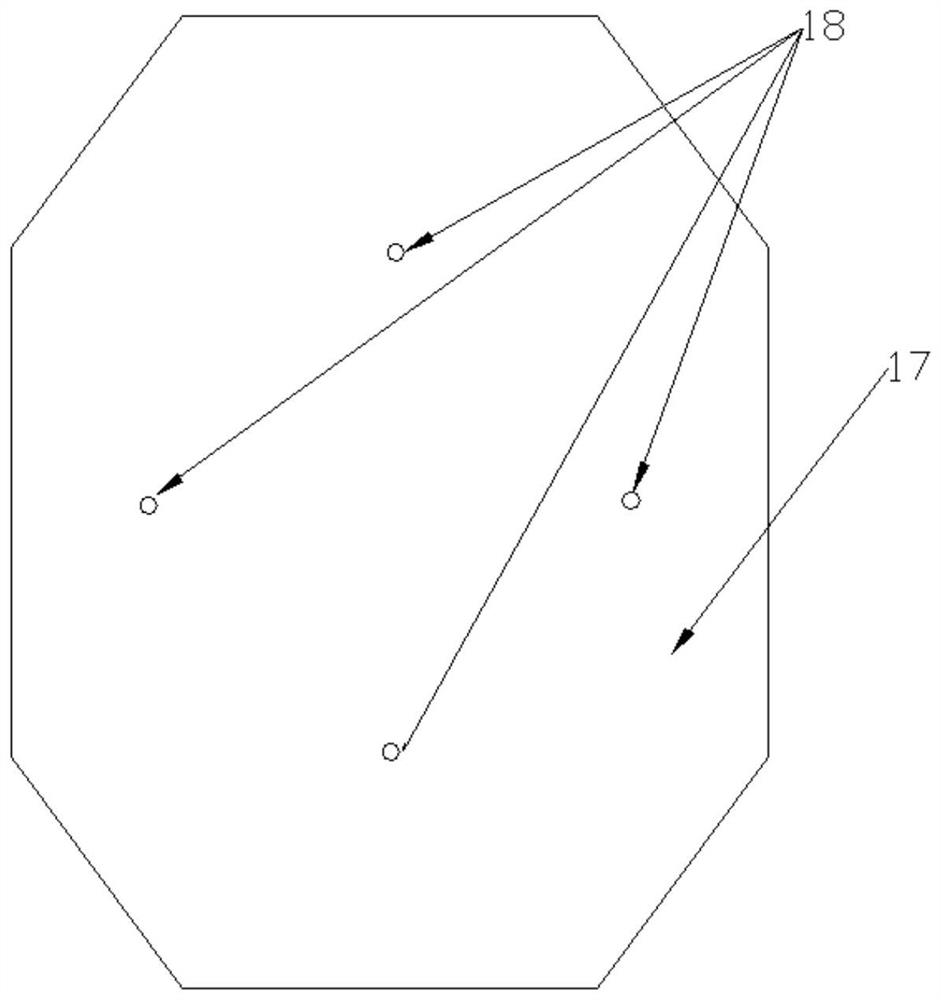

The invention relates to a method for preparing a low-density heat-resistant composite material revolving body. The method includes four steps: (1) mold clamping; (2) sol perfusion; (3) sol defoaming and (4) product molding. By coordinating the positional relationship between the glue storage device and the mould, the present invention realizes the optimized molding of low-density heat-resistant composite material revolving body parts; a high-precision low-pressure regulating valve (3) is installed on the air pressure pipeline to precisely control the foam discharge time The pressure in the mould; at the same time, the concept of gravity injection was introduced by using the principle of the connecting device, and an electronic platform scale (23) was arranged under the material tank (7) to fully monitor the injection speed; The relationship between the position and size of the glue port (11) and the glue outlet (18) realizes the full removal of gas, improves the internal quality of the low-density heat-resistant composite rotary body parts, improves the success rate of the rotary body parts, and reduces the Manufacturing cost of rotary parts.

Description

A kind of preparation method of low-density heat-proof composite material rotary body parts technical field The present invention relates to the low-density heat-proof composite material preparation field, especially relate to a kind of low-density heat-proof composite material Preparation method of rotary body parts. Background technique When the aircraft is flying at high speed in the atmosphere, a large amount of aerodynamic heat will be generated by squeezing and rubbing the air, so each All high-speed aircrafts face serious thermal barrier problems. If the external heat is not effectively managed and controlled, it will cause flight The device overheats or even burns out. Therefore, thermal protection materials are required to protect aircraft structures and internal equipment. As the most important ablation matrix material, resin-based thermal protection material has high specific strength and specific modulus, fatigue resistance, It has the characteristics...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C70/46B29C70/54

CPCB29C70/46B29C70/54B29C70/545Y02T50/40

Inventor 龙东辉曹宇张亚运王丹丹

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com