Rotary gas explosion sound source

A rotary and sound source technology, which is applied to ships, ship weapons, transportation and packaging, etc., can solve the problems of limited sound power and inability to simulate ship noise well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

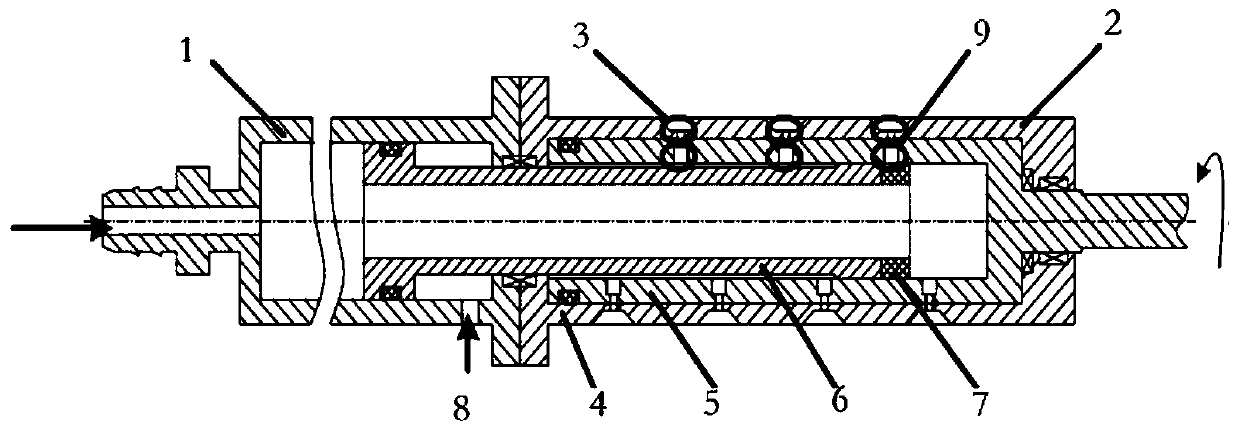

[0021] as attached figure 1 As shown, the present invention provides a rotary gas explosion sound source, and the sound source structurally includes a stator, a rotor 5 and a piston 6; wherein the stator is composed of a left end cover 1 and a right end cover 2, and the left end cover 1 and the right end cover 2 are butted There is a circumferential limiter in the formed cylinder. The rotor 5 is located inside the right end cover 2 and is axially limited by the limiter. The rotating shaft of the rotor 5 passes through the center hole on the end face of the right end cover 2 and is connected to the servo motor. .

[0022] The tail of the piston 6 has a spigot, and the front end is installed with a seal 7 and then sleeved in the inner cavity of the rotor. The tail of the piston 6 is located inside the left end cover, and the axial displacement of the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com