Coating clamp

A fixture and locking block technology, which is applied in the field of lifting fixtures, can solve problems such as difficult load and uniform coating, and achieve the effects of widening the size limit of coating products, ensuring stable performance, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

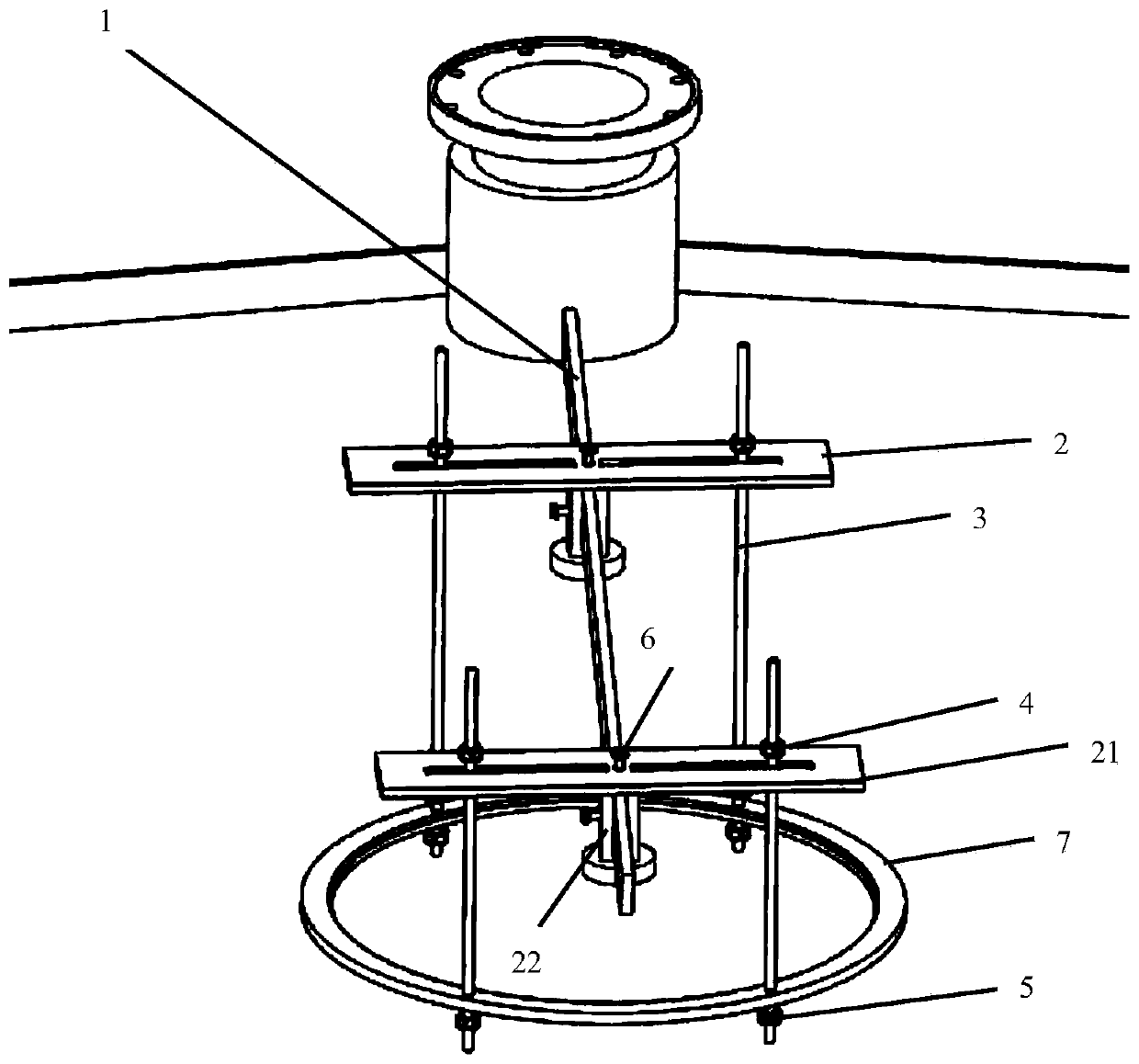

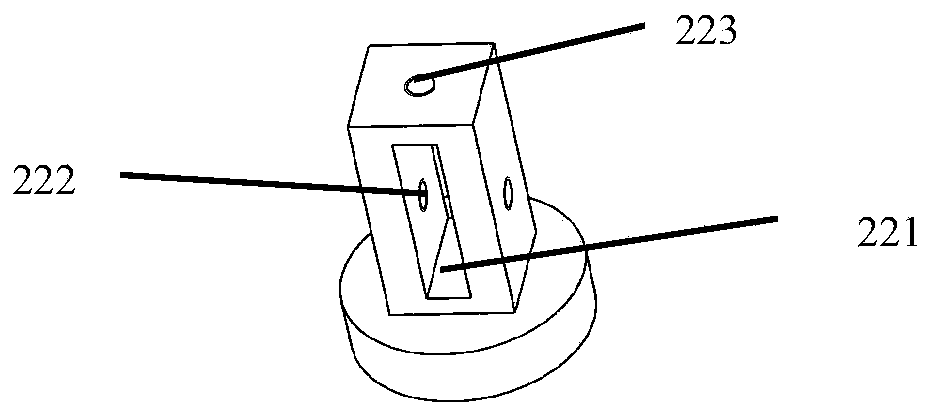

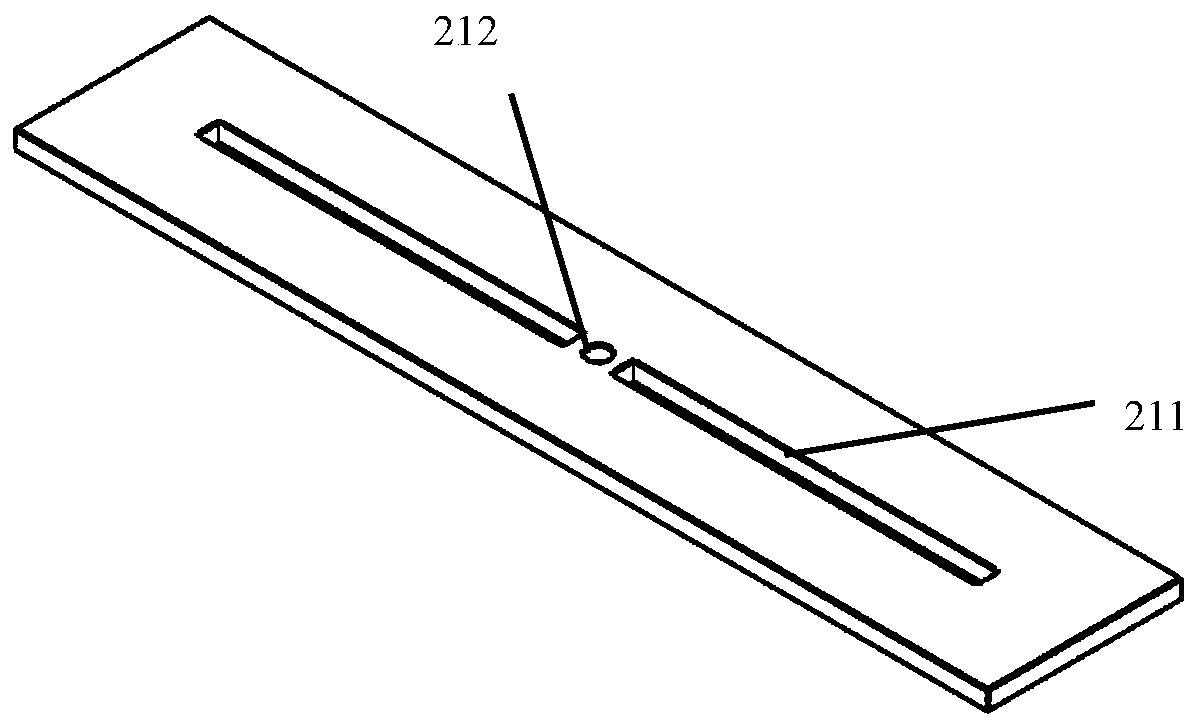

[0033] according to Figure 1 to Figure 4 A kind of coating fixture shown, comprises T-shaped locking block 2, and the vertical plate 22 of described locking block 2 is horizontally provided with and is used for penetrating the horizontal through hole 221 of coating umbrella stand beam 1 and with described horizontal through hole 221 side. Threaded hole I222 through; the horizontal plate 21 of the locking block 2 is provided with an oblong hole 211 passing through up and down, and the screw rod 3 for penetrating the fixed coating tooling 7 is set in the oblong hole 211, and the screw rod 3 passes through the upper 1. The lower positioning nut 4 is relatively clamped and fixed in the oblong hole 211 , and the bottom end of the screw rod 3 is screw-fixed with a supporting nut 5 for supporting the coating tooling 7 . At least two locking blocks 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com