Process wire winding device

A winding device and process line technology, applied in the field of process line production equipment, can solve the problems of lack of winding processing equipment, low work efficiency, and uncontrollable quality, and achieve the effects of convenient operation, improved work efficiency, and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

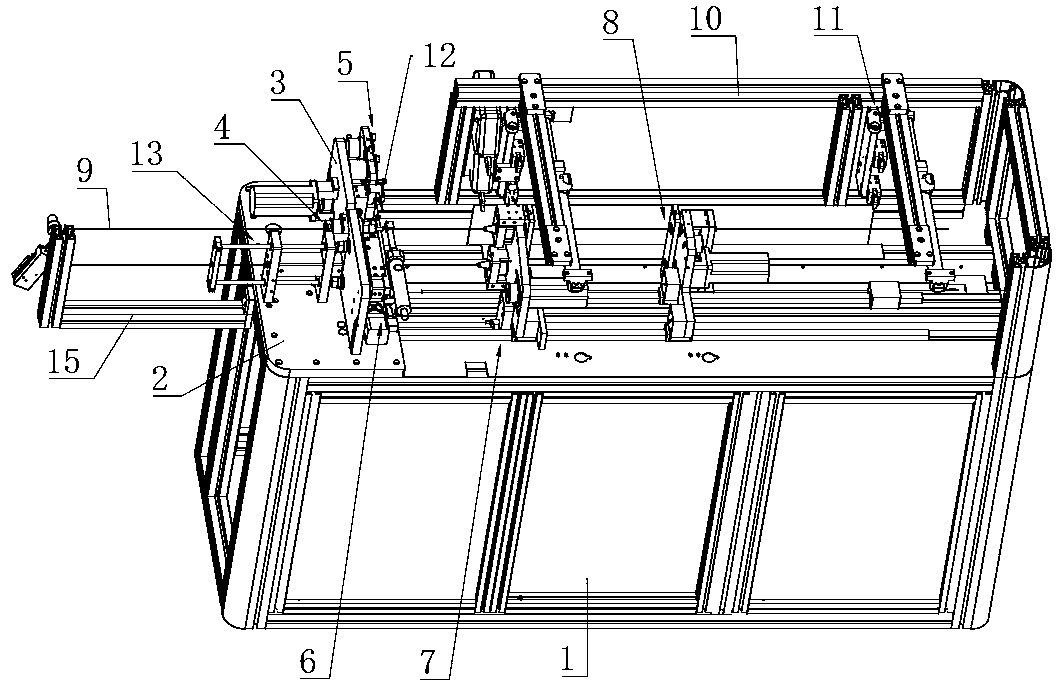

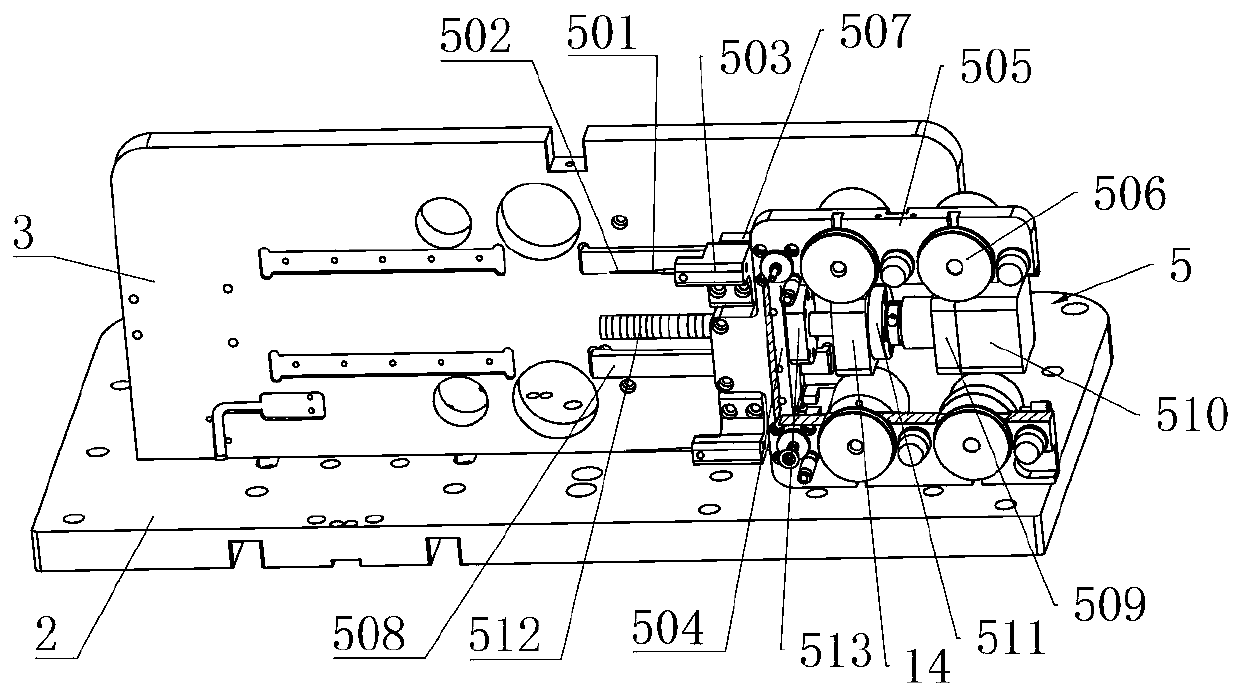

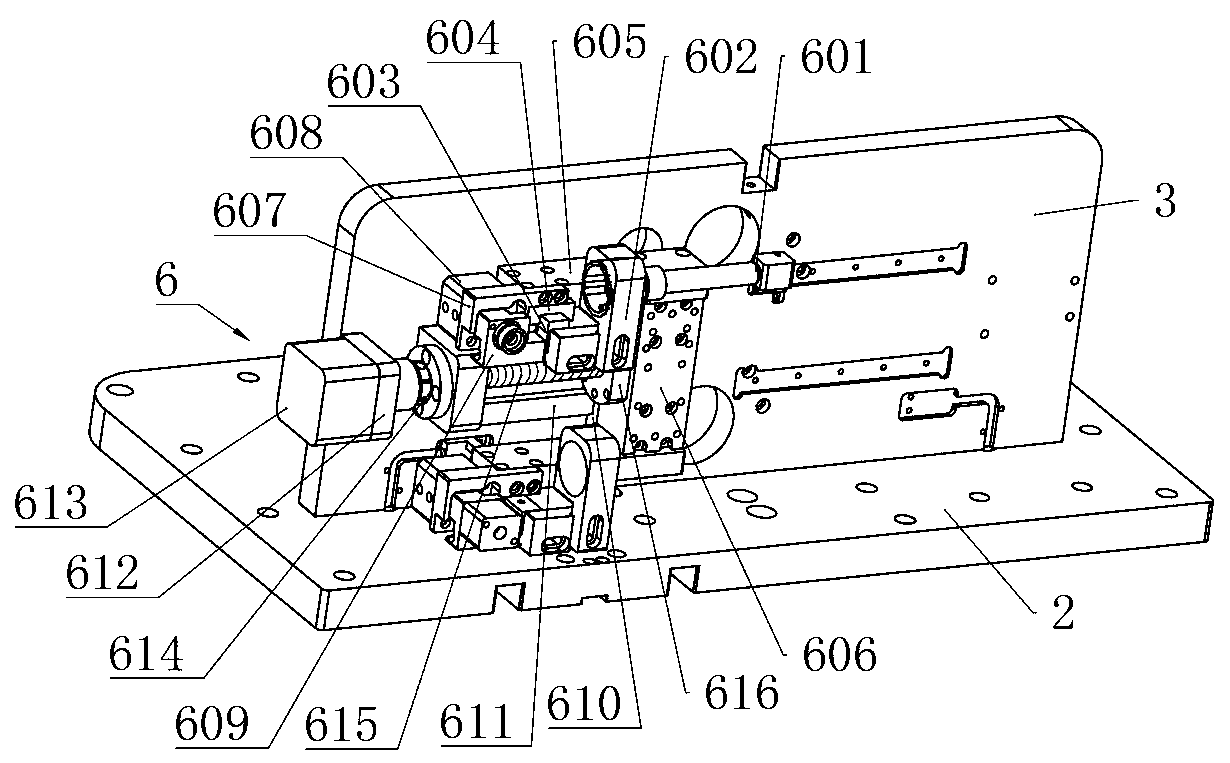

[0049] In this example, combined with Figure 1-Figure 7 As shown, a process line 9 winding device includes a box body 1, a workbench 2 is mounted on the bolts on the box body 1, a first support plate 3 is installed on the bolts on the workbench 2, and one side of the first support plate 3 is provided There is a fixed winding mechanism 4, and the other side is provided with a movable threading mechanism 5 and a movable welding and bonding mechanism 6, and the threading mechanism 5 is set opposite to the welding and bonding mechanism 6. By setting the threading mechanism 5, the winding The thread 12 pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com