A kind of preparation method of woolen fabric

A wool fabric and woolen spinning technology, applied in the field of textile fabrics, can solve the problems of incompatibility of fabric stiffness and warmth retention, and achieve the effect of full hand feeling, good moisture permeability and air permeability, and widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of woolen fabric, its process is as follows:

[0040] (1) prepare the monofilament of different shrinkage linen-like polyester fiber:

[0041] (1.1) After PET (intrinsic viscosity is 0.63dL / g) is spun according to the POY process and the FDY process, it is plied and paralleled; the mass ratio of the POY silk produced by the POY process to the FDY silk produced by the FDY process is 50 :50;

[0042] The spinneret hole on the spinneret corresponding to the POY process is a conventional trilobal shape; the three lobes of all conventional trilobal spinneret holes have the same length and the same width, and the ratio of length to width is 2.8:1, and the adjacent two lobes The included angle between the centerlines of is 120°;

[0043] The parameters of the POY process are: the cooling wind speed is 0.5m / s;

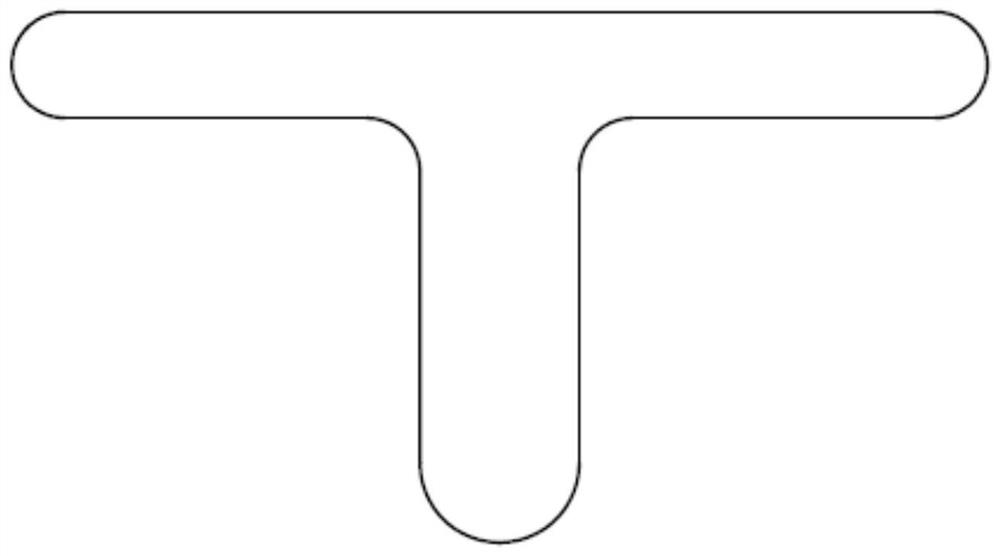

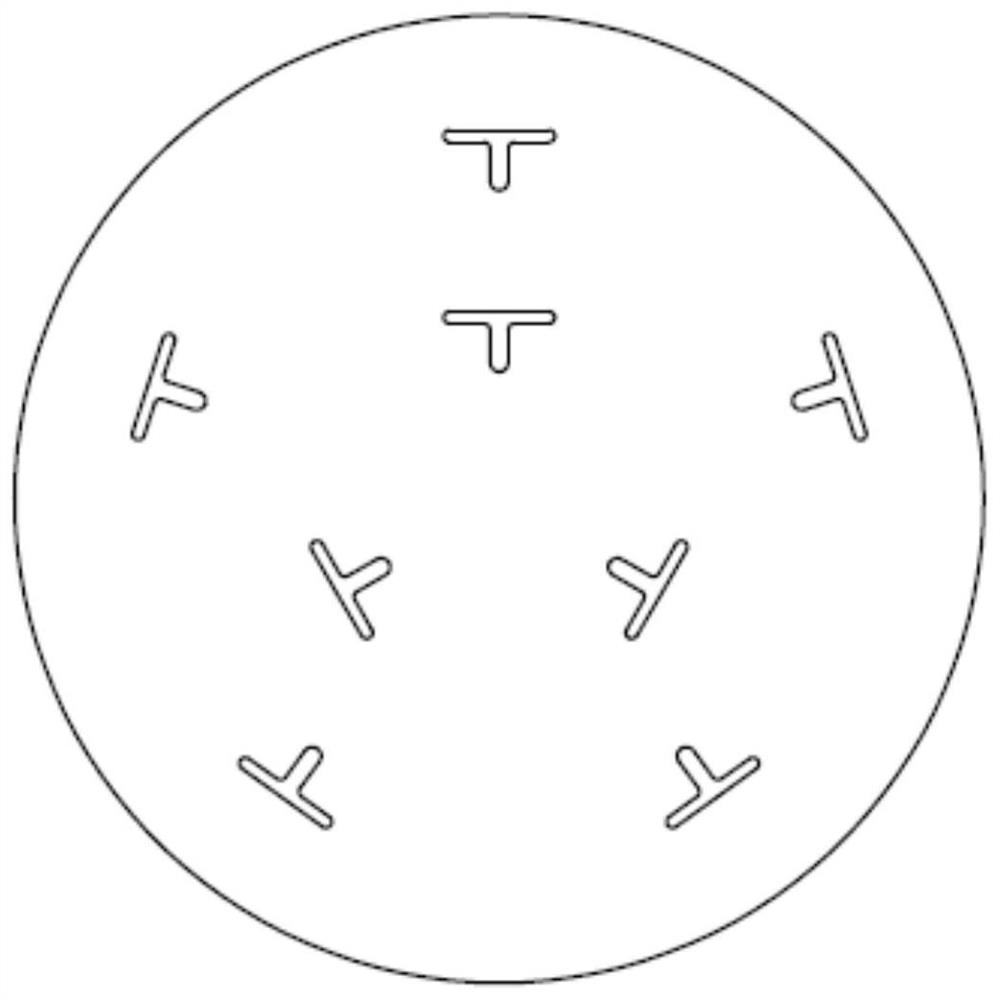

[0044] The spinneret hole on the spinneret corresponding to the FDY process is a T-shaped three-lobed spinneret; the three leaves of all...

Embodiment 2

[0052] A kind of preparation method of woolen fabric, its process is as follows:

[0053] (1) prepare the monofilament of different shrinkage linen-like polyester fiber:

[0054] (1.1) After PET (intrinsic viscosity is 0.6dL / g) is spun by POY process and FDY process, it is plied and paralleled; the mass ratio of POY silk produced by POY process to FDY silk produced by FDY process is 30 :70;

[0055] The spinneret hole on the spinneret corresponding to the POY process is a conventional trilobal shape; the three lobes of all conventional trilobal spinneret holes have the same length and the same width, and the ratio of length to width is 3.2:1, and the adjacent two lobes The included angle between the centerlines of is 120°;

[0056] The parameters of the POY process are: the cooling wind speed is 0.5m / s;

[0057] The spinneret hole on the spinneret corresponding to the FDY process is a T-shaped three-lobed spinneret; the three leaves of all T-shaped three-lobed spinneret hol...

Embodiment 3

[0065] A kind of preparation method of woolen fabric, its process is as follows:

[0066] (1) prepare the monofilament of different shrinkage linen-like polyester fiber:

[0067] (1.1) After PET (intrinsic viscosity is 0.6dL / g) is spun by POY process and FDY process, it is plied and paralleled; the mass ratio of POY silk produced by POY process to FDY silk produced by FDY process is 40 :60;

[0068] The spinneret hole on the spinneret corresponding to the POY process is a conventional trilobal shape; the three lobes of all conventional trilobal spinneret holes have the same length and the same width, and the ratio of length to width is 3:1, and the adjacent two lobes The included angle between the centerlines of is 120°;

[0069] The parameters of the POY process are: the cooling wind speed is 0.3m / s;

[0070] The spinneret hole on the spinneret corresponding to the FDY process is a T-shaped three-lobed spinneret; the three leaves of all T-shaped three-lobed spinneret holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com