Preparation method of printed fabric

A fabric and printing technology, applied in the field of printing fabric preparation, can solve the problem of insufficient color penetration on the back of a single digital printing, and achieve the effect of strong texture, strong personality and visual impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

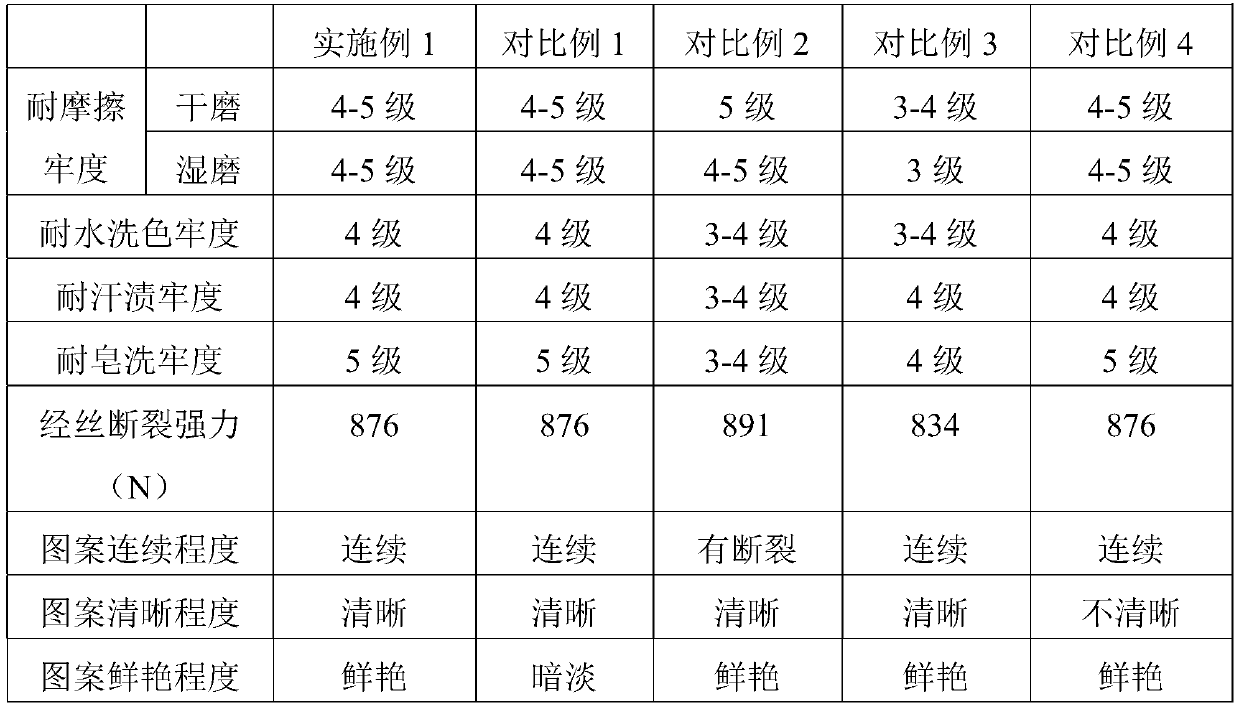

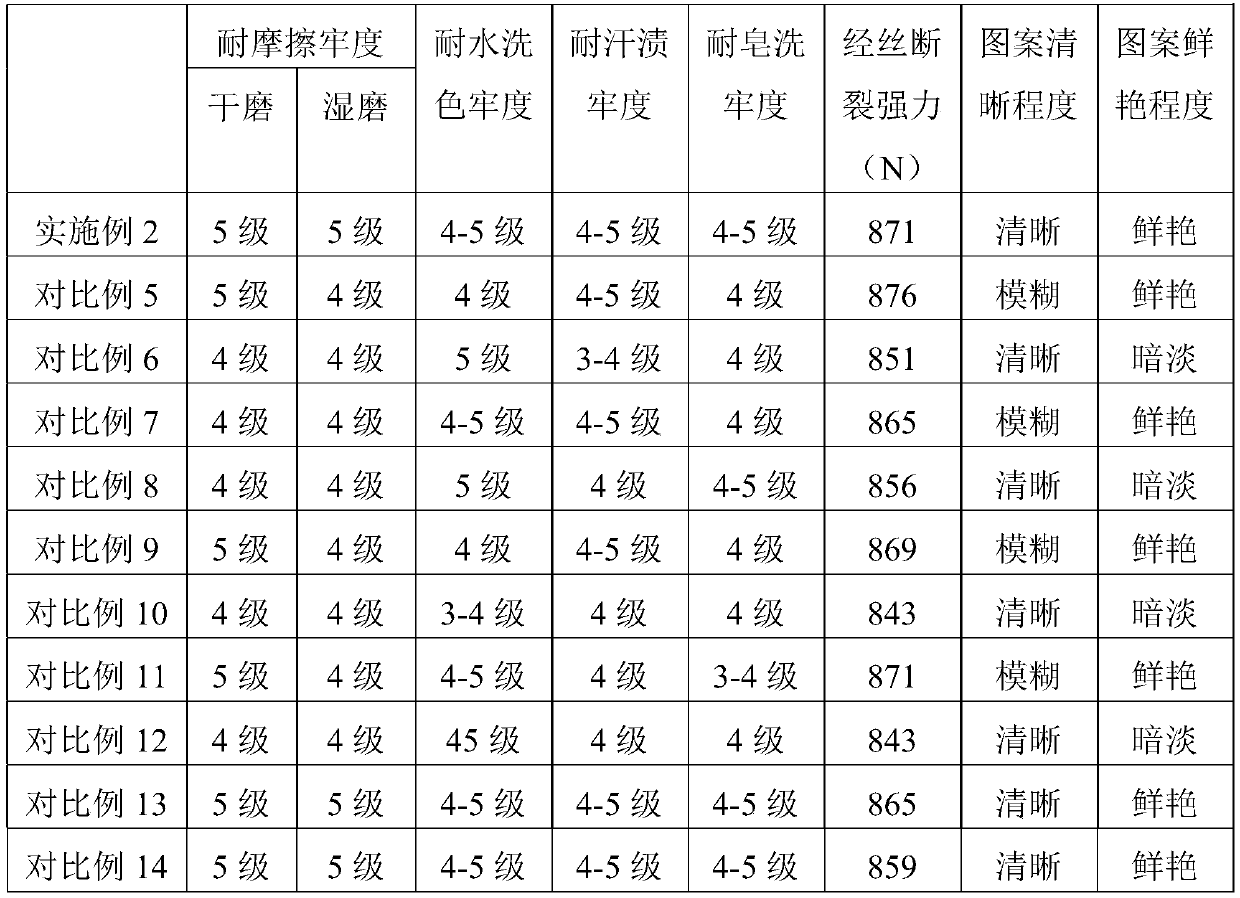

Examples

Embodiment 1

[0023] A kind of preparation method of printed fabric, described preparation method specifically comprises the following steps:

[0024] (a) Dyeing and weaving the warp and weft yarns with reactive dyes to obtain yarn-dyed fabrics, and pretreating the yarn-dyed fabrics, the pretreatment including desizing and sizing operations;

[0025] (b) according to the cloth sample of the yarn-dyed fabric after the pretreatment that step (a) obtains, select the pattern that is suitable for this yarn-dyed fabric, carry out printing process to the yarn-dyed fabric;

[0026] (c) Post-processing the printed yarn-dyed fabric obtained in step (b) to obtain the printed fabric.

[0027] Among them, yarn-dyed fabrics are interwoven with warp yarns of 50-120 counts and weft yarns of 50-120 counts, and the warp yarn density is 135×71 or 179×110 or 190×110 or 250×105 or 286×115 or 105× per inch 95 or 128×65 or 65×75, the weft density is 133×73 or 173×120 or 200×100 or 255×100 or 288×120 or 110×90 or...

Embodiment 2

[0041] Compared with Example 1, most of them are the same, except that it is further defined in this example:

[0042] In step (c), the post-treatment includes steaming and color-fixing operation, water washing and softening operation and tenter setting operation in sequence. -18min steaming and color fixing. The washing and softening operation specifically includes: washing the steamed and color-fixed base fabric with water at a temperature of 95-100°C, and then performing softening treatment after washing. The tentering operation specifically includes: performing tentering at a temperature of 140-160° C. at a speed of 73-78 m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com