Structure and method for reducing surge phenomenon of centrifugal compressor and automatically adjusting flow

A centrifugal compressor, automatic adjustment technology, applied in the direction of machine/engine, mechanical equipment, non-variable-capacity pump, etc., can solve the low safety and reliability of centrifugal surge protection, and cannot effectively achieve centrifugal compressor. The purpose of surge protection and other issues, to achieve the effect of reducing the surge phenomenon and automatically adjusting the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

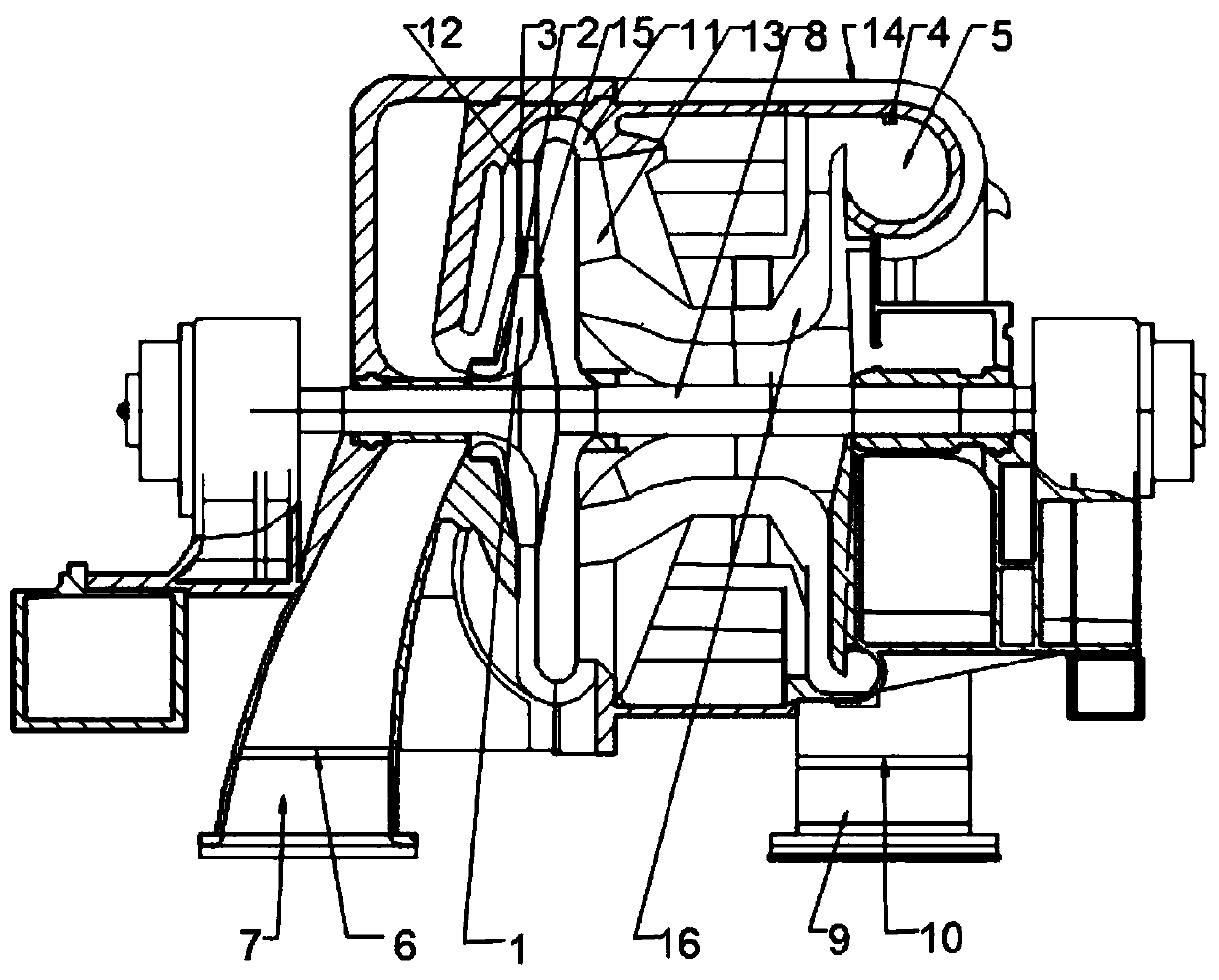

[0038] The invention provides a structure and method for reducing the surge phenomenon of a centrifugal compressor and automatically adjusting the flow rate, including the following:

[0039] see figure 2 with Image 6 , when the centrifugal compressor is running, the vibration sensor (2) detects the vibration frequency, and transmits the data to the data processing module (21) of the vibration detector, and the data processing module (21) of the vibration detector transmits the data to the computer (18), Computer (18) transmits data on the display (19), and shows on the display (19).

[0040] see figure 2 with Image 6 When the centrifugal compressor is running, the thermocouple (3) detects the temperature in the casing, the thermocouple (3) transmits the data to the thermocouple data processing module (22), and the thermocouple data processing module (22) transmits the detection result To computer (18), computer (18) transmits data on the display (19), shows on display...

example 2

[0048] The invention provides a structure and method for reducing the surge phenomenon of a centrifugal compressor and automatically adjusting the flow rate, including the following:

[0049] see Image 6 , Figure 8 , when the centrifugal compressor is running, when the flow display meter No. 2 (10) measures the flow rate of the exhaust pipe (9) at this time to be d1, it is transmitted to the PLC (17), and the vibration frequency measured by the vibration detector (2) is It is transmitted to PLC (17) for k0. The PLC (17) transmits the data to the computer (18). According to the established relationship between the vibration frequency and the flow rate of the exhaust pipe (9), the computer (18) analyzes that the vibration frequency is k2-k3 as the normal working area, k1-k2 as the surge area, and greater than k3 as the resistance stagnation area. When k0 is in the k2-k3 area, the computer judges that k0 is in the k2-k3 area at this time, and this area is the normal working...

example 3

[0051] The invention provides a structure and method for reducing the surge phenomenon of a centrifugal compressor and automatically adjusting the flow rate, including the following:

[0052] see Image 6 , Figure 9 , when the centrifugal compressor is running, when the flow display meter No. 2 (10) measures the flow rate of the exhaust pipe (9) at this time, y1 is transmitted to the PLC (17), and the flow display meter No. 1 measures the suction port (7) The flow is transmitted to PLC (17) for c0. The PLC (17) transmits the data to the computer (18). The computer (18) analyzes the relationship between the flow of the suction port (7) and the flow of the exhaust pipe (9) based on the established flow, and the flow at this time is c2-c3, which is the normal working area, and c1-c2 is the surge area, Greater than c3 is the block zone. When c0 is in the c2-c3 area, the computer judges that c0 is in the c2-c3 area at this time, this area is the normal working area, and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com