Symmetric metering pump transmission mechanism with sliding block frame connecting rod and metering pump

A transmission mechanism and opposed technology, which is applied in the direction of transmission, machine/engine, liquid variable capacity machinery, etc., can solve the problem that the thrust is not in a straight line, etc., and achieve the effect of strong load bearing capacity and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

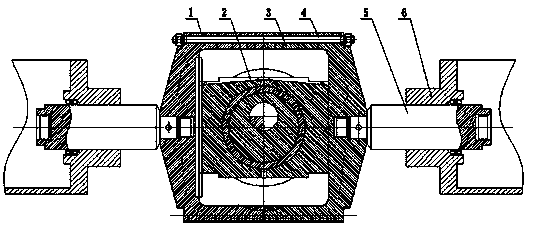

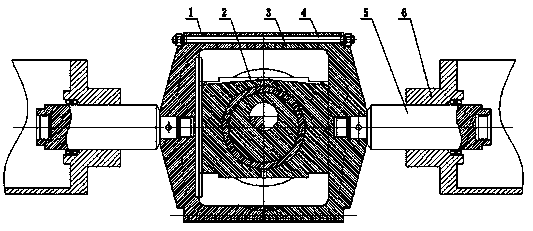

[0022] Such as figure 1 , in an embodiment of the present invention, a metering pump transmission mechanism of an opposed slider frame connecting rod, comprising:

[0023] Slider frame connecting rod part, described slider frame connecting rod part comprises left slider frame 1, slider 2, right slider frame 3 and slider connecting rod 4, described left slider frame 1, right slider frame 3. The slider connecting rod 4 is symmetrically arranged, and the slider 2 is slidably installed in the left slider frame 1 and the right slider frame 3;

[0024] The connecting part, the transmission part is connected with the slider frame connecting rod part through the connecting part, and the transmission part drives the slider frame connecting rod part to work through the connecting part; and the transmission part and the guide part, the two sets of guide parts are relatively installed on the On both sides of the block frame connecting rod part, the guide part is used to limit the support...

Embodiment 2

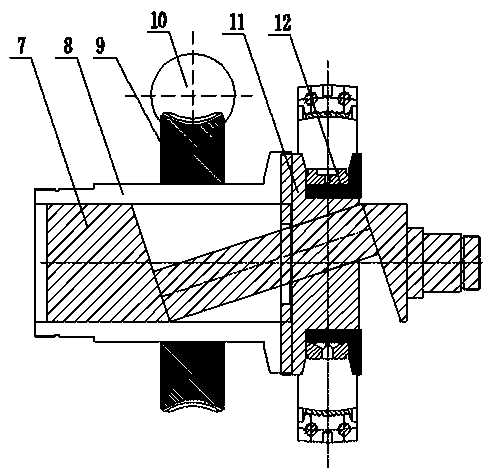

[0036] A metering pump with opposed slider frame and connecting rod, including a motor, a transmission box and double hydraulic ends, and also includes the metering pump transmission mechanism of the opposed slider frame and connecting rod as described above, the transmission box The body is symmetrically provided with double pump heads, the double fluid ends are double pump heads, the double liquid ends are connected with the guide components, and the motor provides power.

[0037] Specifically, the motor drives the worm 10 to rotate directly or through a coupling, the worm 10 drives the worm wheel 9 to rotate, the worm wheel 9 and the sleeve shaft 8 are connected and fixed by key pins, the sleeve shaft 8 and the eccentric wheel 11 are connected in a cross, and finally drive the eccentric wheel 11 Rotate, the N-shaped shaft 7 and the eccentric wheel 11 drive the slider 2 to rotate, the guide shaft 5 is limited by the guide sleeve 6, and cannot rotate, and the slider 2 slides u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com