Heat exchange device applied into kiln head hood of rotary kiln

A technology of heat exchange device and kiln hood, which is applied in the field of heat exchange devices, can solve the problems of thermal radiation, ineffective use of heat, waste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Examples:

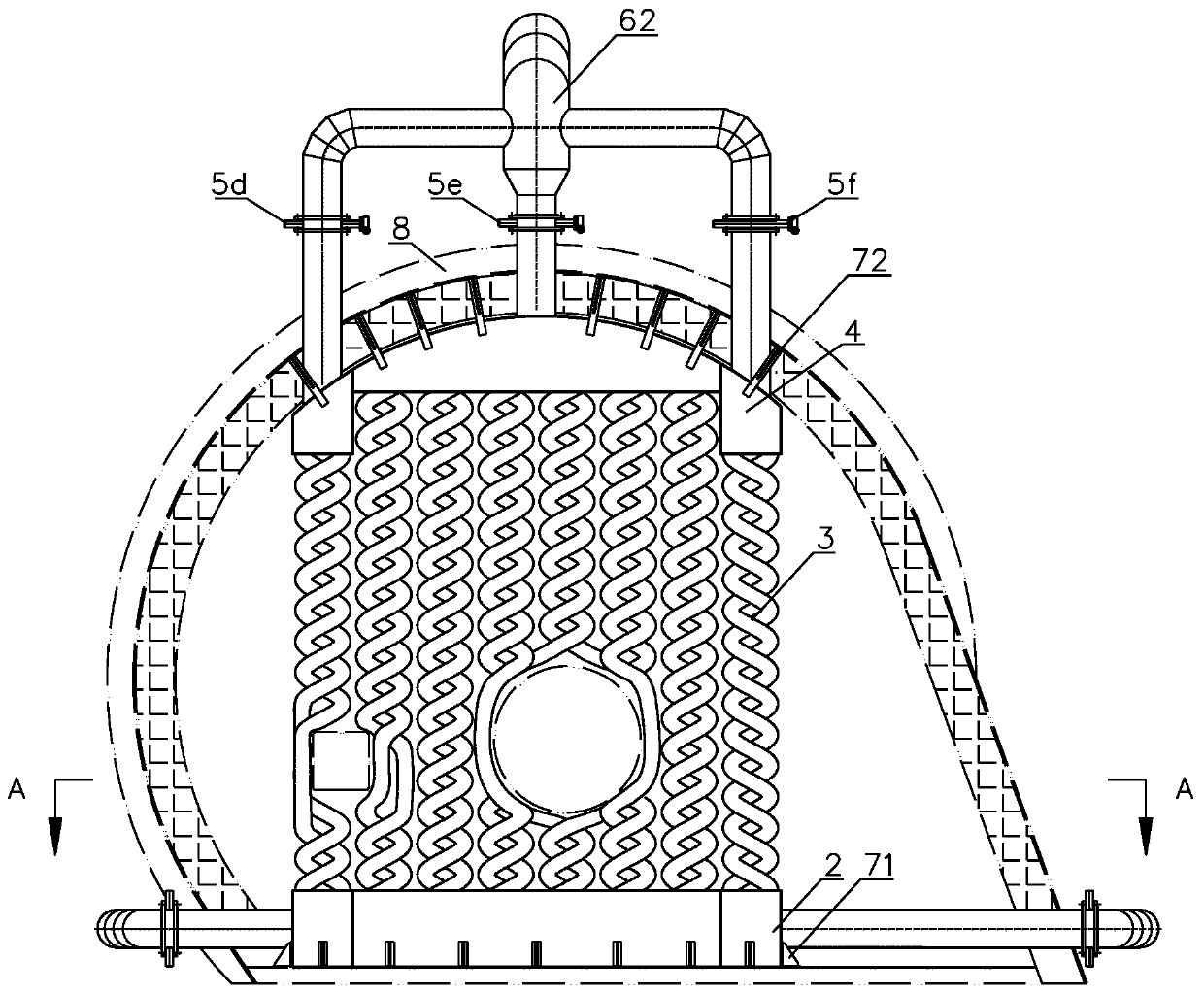

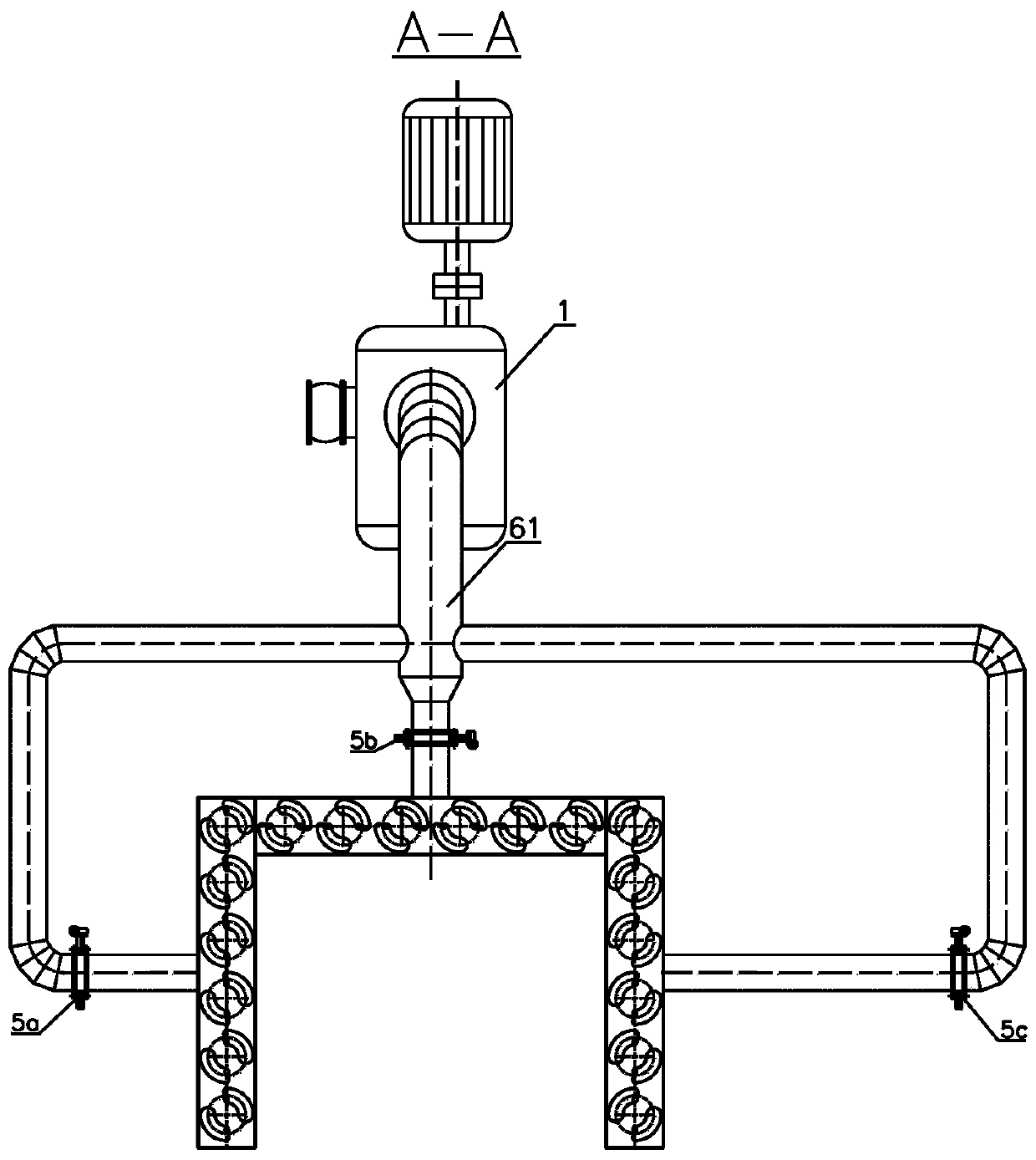

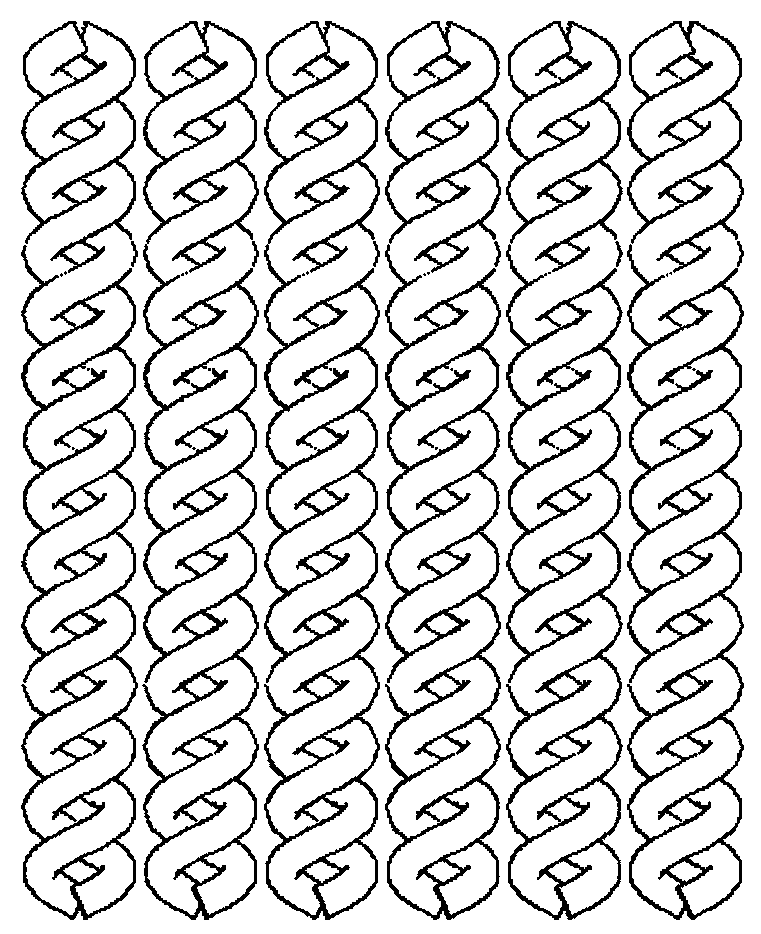

[0030] Such as figure 1 , figure 2 As shown, a heat exchange device used in the hood of a rotary kiln includes a fan 1, a lower gas collecting box 2, a radiant tube 3, an upper gas collecting box 4, valves, pipes and brackets.

[0031] There are three lower gas collecting boxes 2, the lower gas collecting box 2 is made of 0Cr18Ni9 material, the lower gas collecting box 2 is a rectangular box structure, and the upper surface is provided with a circular hole corresponding to the radiant tube 3. The diameter of the circular hole is the same as that of the radiant tube 3. The diameter is the same. The lower gas collecting box 2 is welded to the internal steel structure of the kiln head cover 8 through the lower bracket 71.

[0032] Fan 1 adopts Roots blower, the flow of Roots blower is 6000m 3 / h, arranged outside the lower gas collecting box 2, the fan 1 is connected to the main input pipe 61, the main input pipe 61 is divided into 3 input branches, each input branc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap