Bus differential protection interval CT secondary winding polarity consistency verification method

A busbar differential protection and busbar protection technology, which is applied in the direction of electric winding testing, measuring devices, instruments, etc., can solve the problems of inability to judge the polarity consistency of the CT secondary winding connected to the busbar protection, unintuitive, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

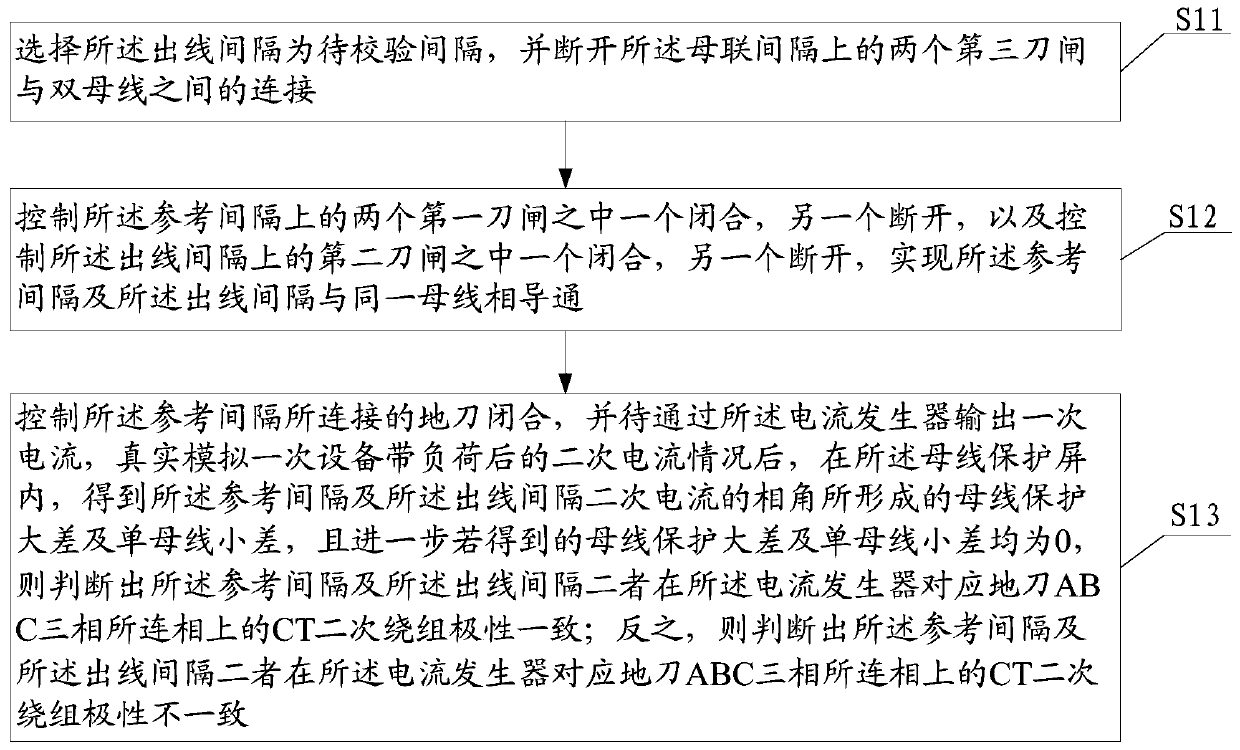

[0054] Such as figure 1 As shown, in Embodiment 1 of the present invention, a method for verifying the consistency of the polarity of the CT secondary windings in each interval of the bus differential protection is provided, which is implemented in the bus protection of the dual bus connection substation configuration; wherein,

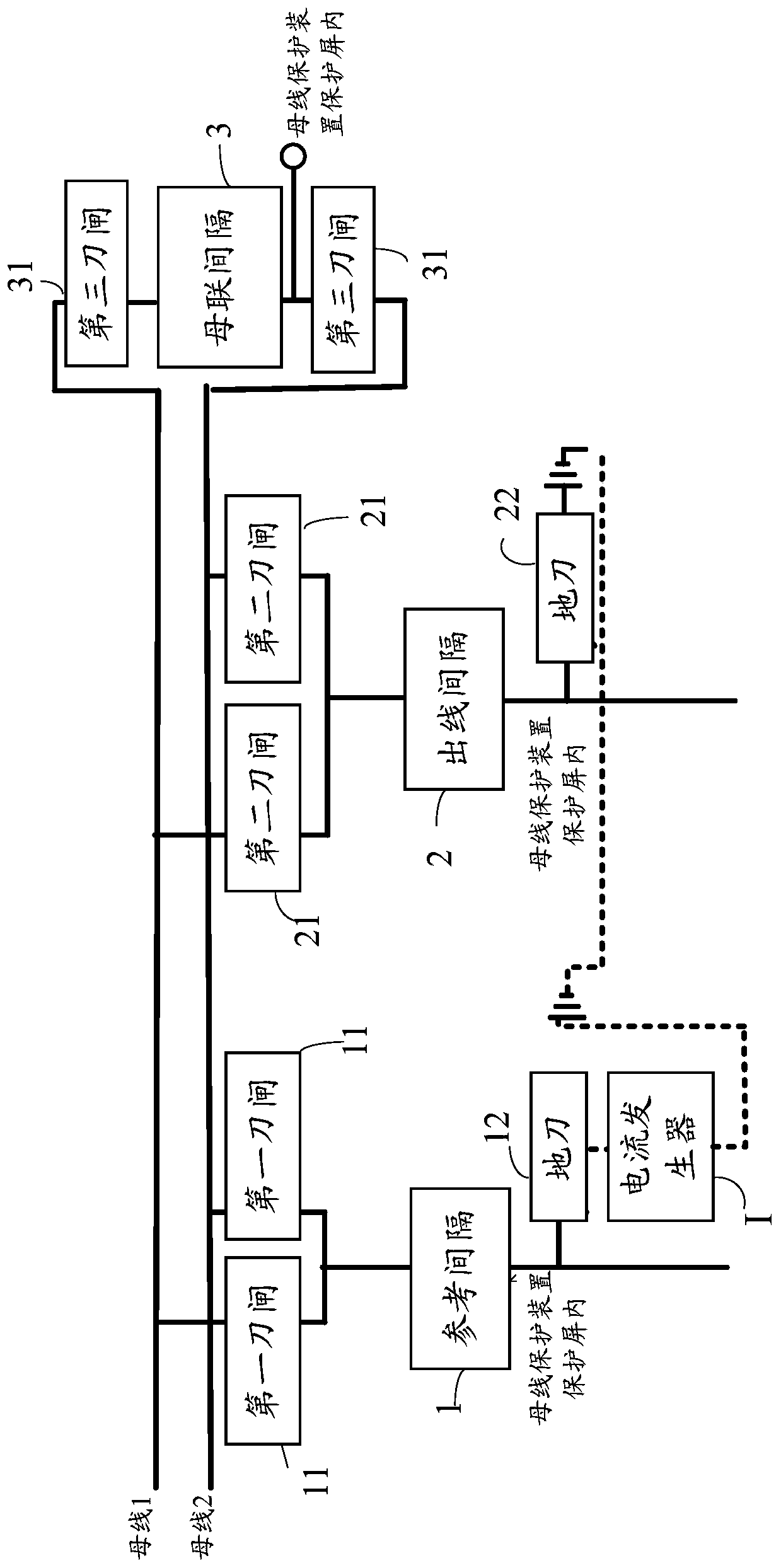

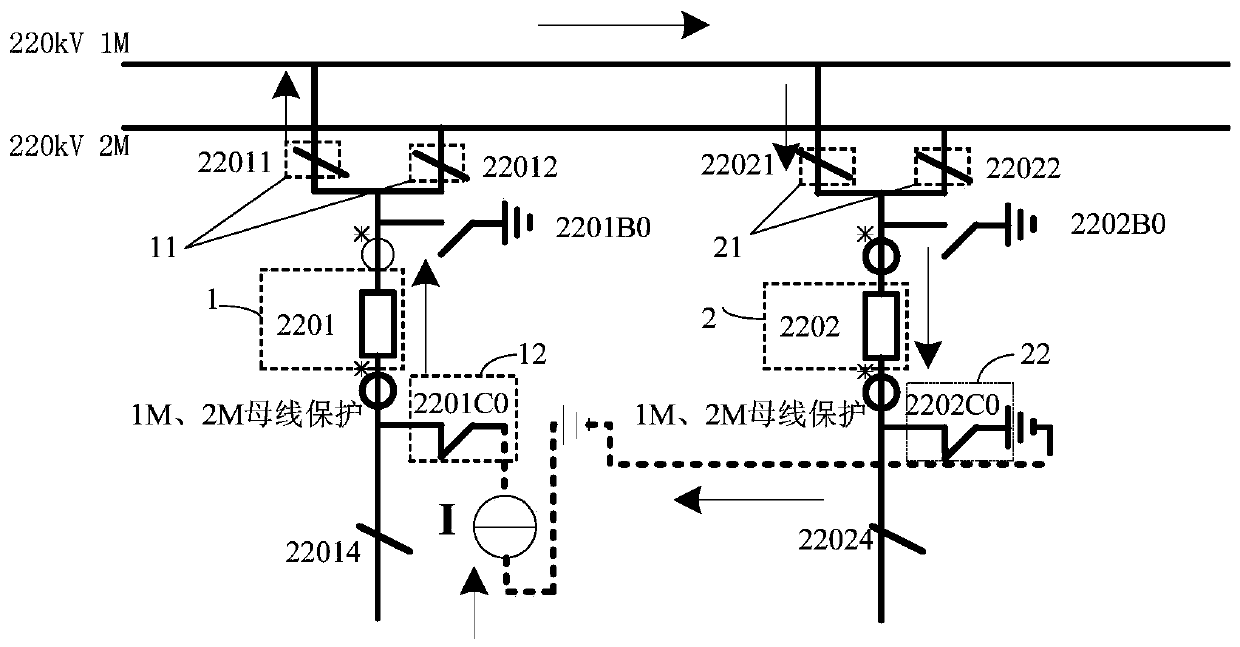

[0055] Such as figure 2 As shown, the busbar protection of the double-bus connection substation is formed with a reference interval 1, an outgoing line interval 2, and a bus coupler interval 3;

[0056] One end of the reference interval 1 is respectively connected to double busbars (such as 1M and 2M) through two first knife gates 11, and the other end is connected to one of the ABC three-phases of a ground knife 12 in the bus protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com