Method for executing safety-related system and equipment periodic test supervision requirements of nuclear power plant

A technology for regular testing and implementation methods, applied in power plant safety devices, nuclear power generation, greenhouse gas reduction, etc. The effect of safety supervision and accident response requirements, simplified U/N classification work, and simplified workflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

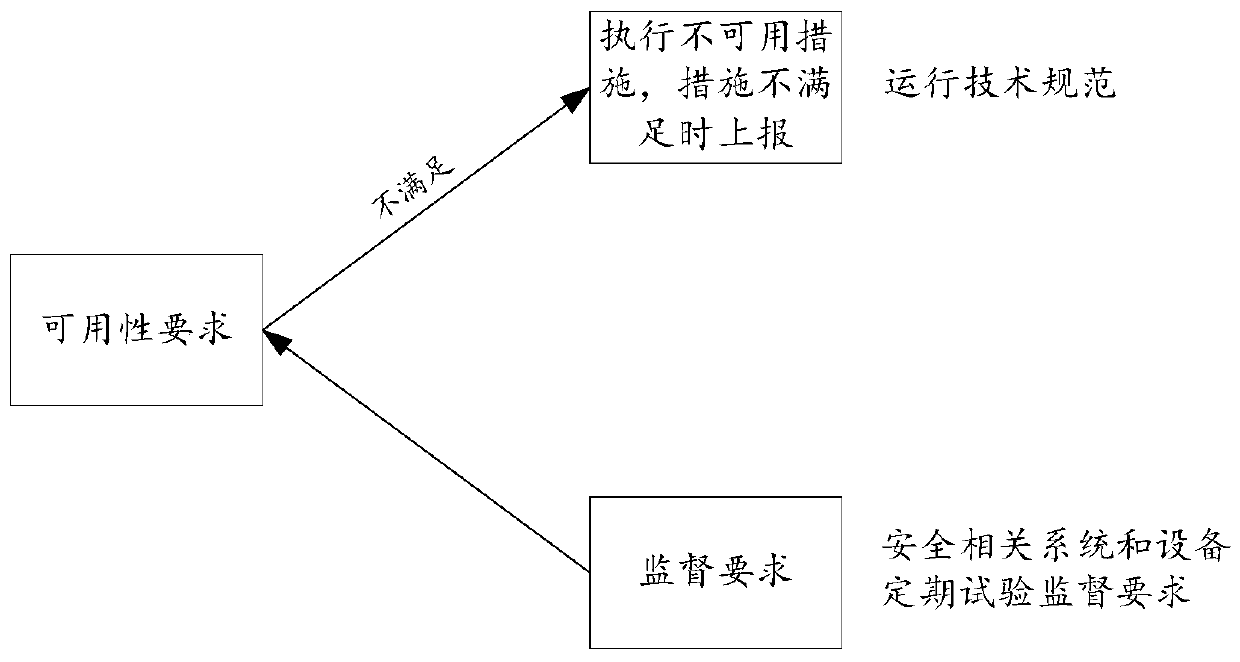

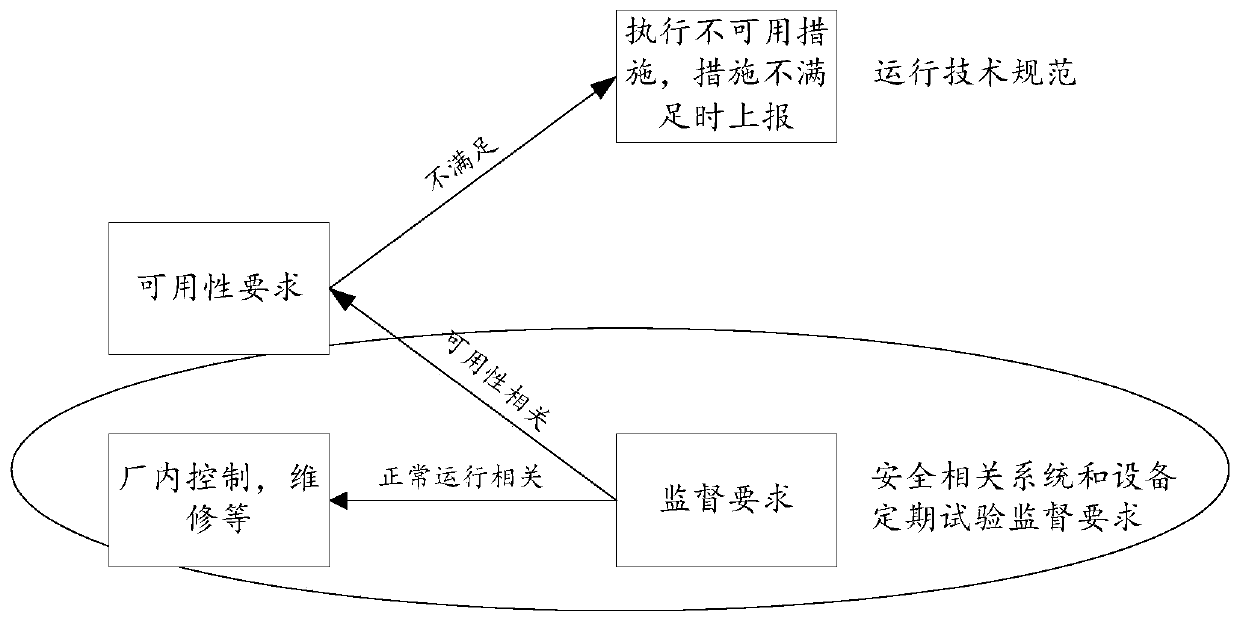

Problems solved by technology

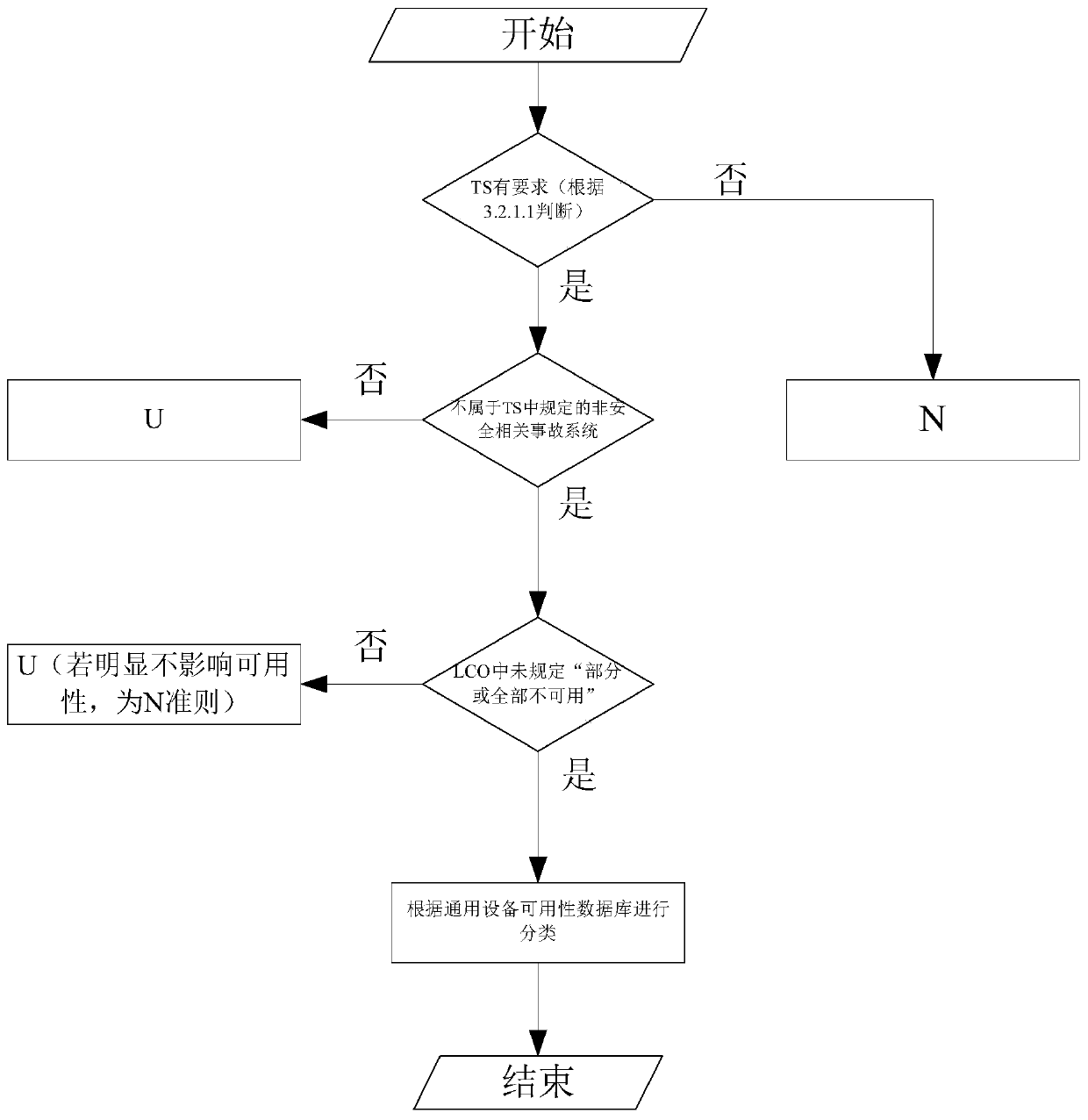

Method used

Image

Examples

Embodiment

[0072] The object of the test is the main feedwater flow regulation system of a pressurized water reactor nuclear power plant. The LCO requirements in the operation technical specification are as follows:

[0073] • Three steam generators including their wide range water gauges must be available.

[0074] The system monitoring requirements are as follows

[0075]

[0076] TS specifies availability requirements for wide-range instruments, the whole system does not belong to non-safety-related accident response system, and “partial or complete unavailability” is not stipulated in LCO, therefore:

[0077] ·There is no requirement in TS for the valves in section 1, the water supply venturi pipe in section 2.3, and the supervision requirements are classified as N guidelines

[0078] The narrow-range liquid level gauge in section 2.1 and the flowmeter in section 2.2 belong to the protection group instruments, which are required to be available in the reactor protection system, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com