A modified carbon carrier, its preparation method and its application in fuel cells

A modified carbon and carbon carrier technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of platinum particle agglomeration and shedding, and reduce the utilization rate of platinum, so as to prevent agglomeration and shedding, reduce hydrophobicity, and improve resistance corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

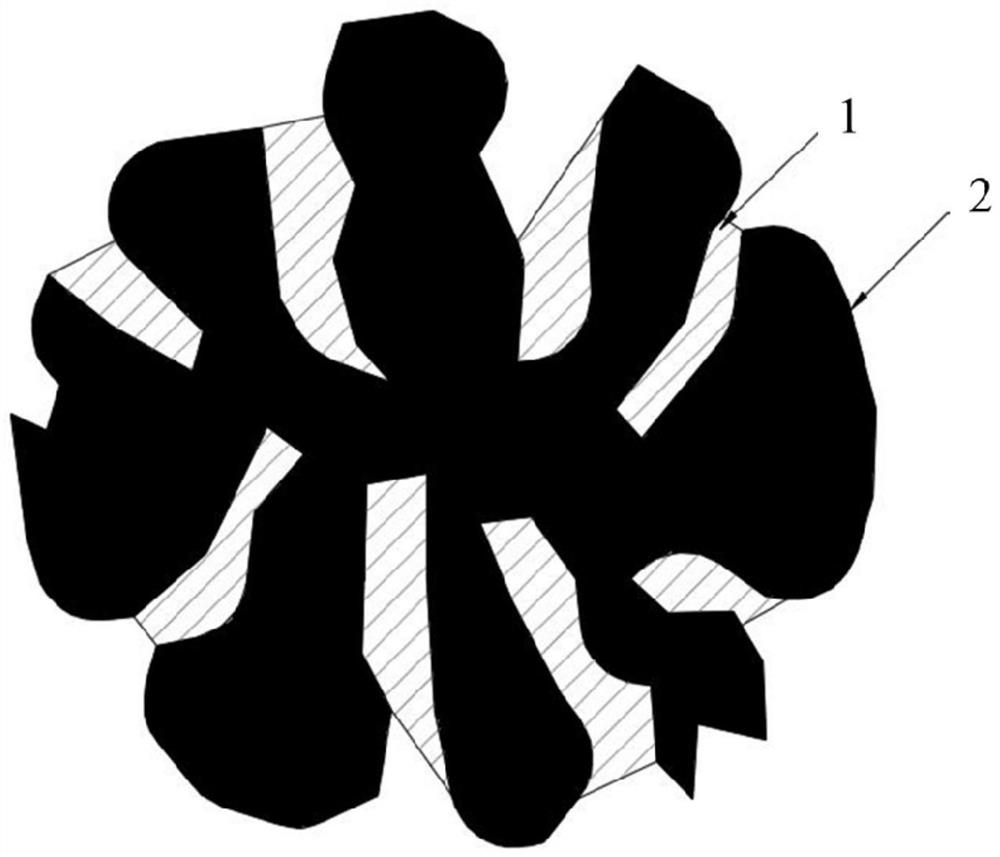

Image

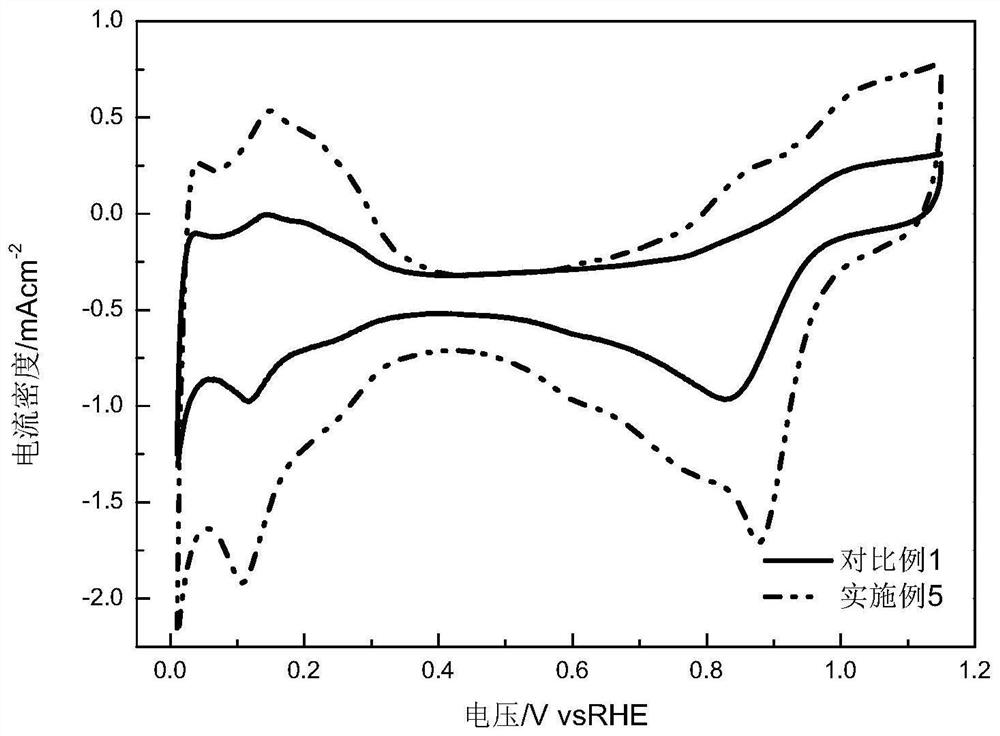

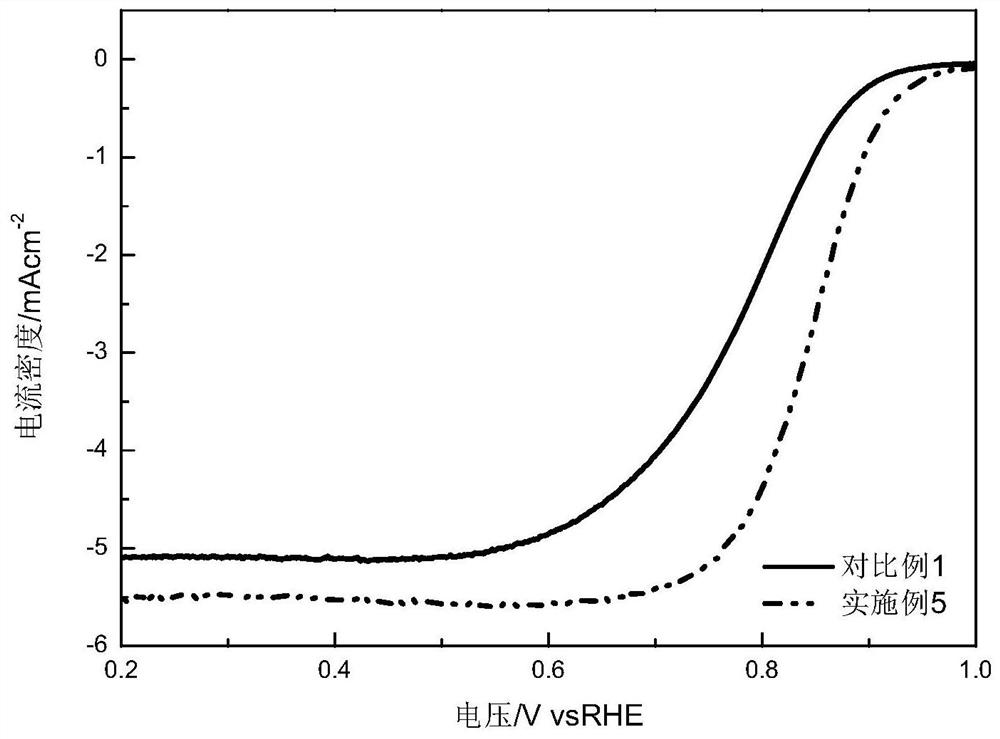

Examples

Embodiment 1

[0075] (1) Add 51 mg of sodium lauryl sulfate into 50 g of deionized water, mix and stir evenly, and make an aqueous dispersant solution;

[0076] (2) Measure 0.2512 g of the dispersant aqueous solution, add 0.3023 g of mesoporous carbon into it, and ultrasonically uniformly obtain solution A;

[0077] (3) Dissolve 0.2mL of 60wt% polytetrafluoroethylene resin dispersion (Daijin Fluorochemical Co., Ltd., D50 particle size is about 30nm) in 6.8mL of deionized water, mix and stir for 10min to make a mass concentration of 1.8% high polymer aqueous dispersion; add 0.0069g sulfonate type anionic fluorosurfactant (Xuejia Fluoro Silicon Chemical Co., Ltd., Actyflon-S100) into the high polymer aqueous dispersion, mix and stir for 10min, and make high The polymer aqueous solution is solution B, and the mass concentration of the sulfonate type anionic fluorosurfactant in the solution B is 0.1%;

[0078] (4) Add solution A of step (2) to solution B of step (3), and mix and stir for 30 minu...

Embodiment 2

[0082] (1) Add 25 mg of polyvinylpyrrolidone and 16 mg of sodium isooctyl polyoxyethylene ether phosphate into 50 g of deionized water, mix and stir evenly, and make an aqueous dispersant solution;

[0083] (2) Measure 0.3813g of dispersant aqueous solution, add 0.2567g graphite, 0.1003g graphene in it, ultrasonic evenly, obtain solution A;

[0084] (3) Dissolve 0.2mL of 60wt% polytetrafluoroethylene resin dispersion (Daijin Fluorochemical Co., Ltd., D50 particle size is about 50nm) in 5.8mL deionized water, mix and stir for 20min, and make the mass concentration 2.1% high polymer aqueous dispersion; add 0.0612g sulfonate type anionic fluorosurfactant (Xuejia Fluoro Silicon Chemical Co., Ltd., Actyflon-S100) into the high polymer aqueous dispersion, mix and stir for 20min, and make high The polymer aqueous solution is solution B, and the mass concentration of the sulfonate type anionic fluorosurfactant in the solution B is 1.0%;

[0085] (4) Add solution A of step (2) to solu...

Embodiment 3

[0089] (1) Add 21 mg of polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer and 14 mg of cetyltrimethylammonium bromide to 50 g of deionized water, mix and stir evenly, and make an aqueous dispersant solution;

[0090] (2) Measure 0.6008g of aqueous dispersant solution, add 0.3567g of carbon black and 0.1935g of carbon fiber into it, mix and stir evenly to obtain solution A;

[0091] (3) Dissolve 1mL of 60wt% polytetrafluoroethylene resin dispersion (Daijin Fluorine Chemical Co., Ltd., D50 particle size is about 70nm) in 11mL of deionized water, mix and stir for 60min, and make a high concentration of 5.0%. Polymer aqueous dispersion; add 0.2409g of diol-type fluorosurfactant (Dajin Fluorine Chemical Co., Ltd., PEG20000) into the high polymer aqueous dispersion, mix and stir for 60min, and make a high polymer aqueous solution, which is solution B , the mass concentration of the diol-type fluorosurfactant in the solution B is 2.0%;

[0092] (4) Add solution A of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com