Water-resistance-excellent cement emulsified asphalt mortar used for plate-type ballastless track

A technology of slab ballastless track and cement emulsified asphalt, which is applied in the field of cement emulsified asphalt mortar, can solve the problems of high water absorption, poor water resistance, and threats to the safe operation of high-speed railways, and achieve good fluidity and stability, suitable mechanical properties, Excellent water resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of water-repellent cement emulsified asphalt mortar in the present embodiment is made of anionic emulsified asphalt, double ion hydroxide emulsified asphalt, P·II type Portland cement, fineness modulus being 1.6 river sand, made of sulfoaluminic acid The expansion agent composed of calcium and gypsum mixed with an appropriate amount of naphthalene sulfonate high-efficiency water reducer and silicone emulsion defoamer and other components, the composition and proportion are shown in Table 6, and the cement is mixed by the single-component feeding method Emulsified asphalt mortar.

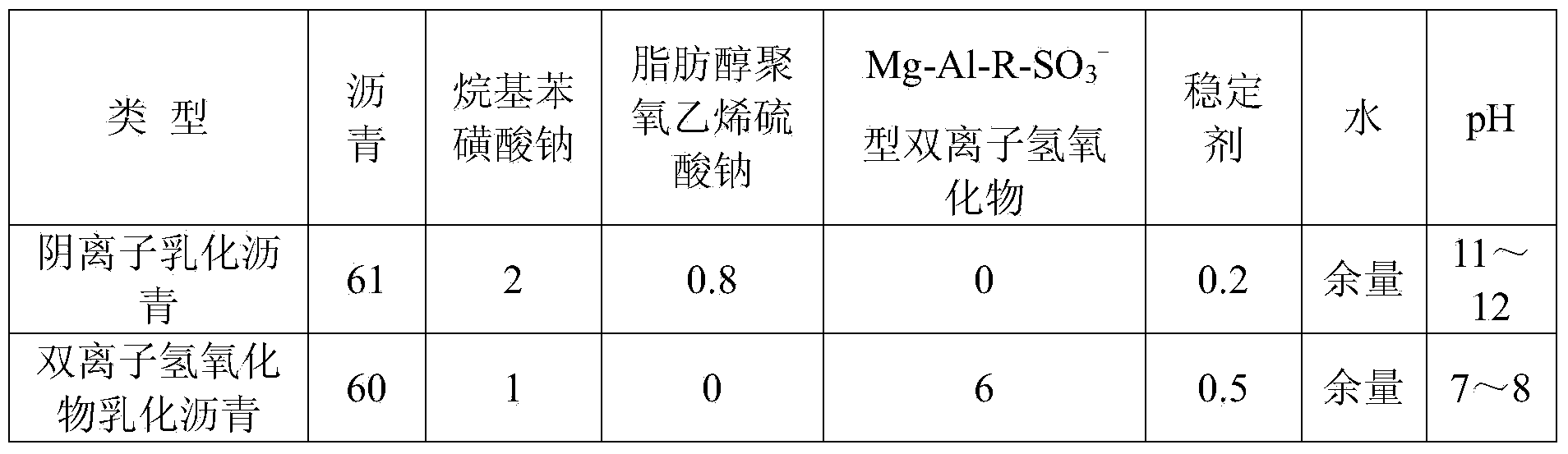

[0056] In this example, the anionic emulsified asphalt is produced by an emulsification process using 70# heavy traffic road petroleum asphalt, sodium alkylbenzene sulfonate with an average molecular weight of 400-500, fatty alcohol polyoxyethylene sodium sulfate, alkyl alcohol stabilizer, and water. , the pH is adjusted to 11-12 with sodium hydroxide NaOH, and its composition and relat...

Embodiment 2

[0060] A kind of hydrophobic cement emulsified asphalt mortar in this example is composed of anionic emulsified asphalt, double ion hydroxide suspension, dry material and an appropriate amount of polycarboxylic acid superplasticizer and silicone emulsion defoamer and other components , its composition and ratio are shown in Table 6, and the cement emulsified asphalt mortar is mixed by the two-component feeding method.

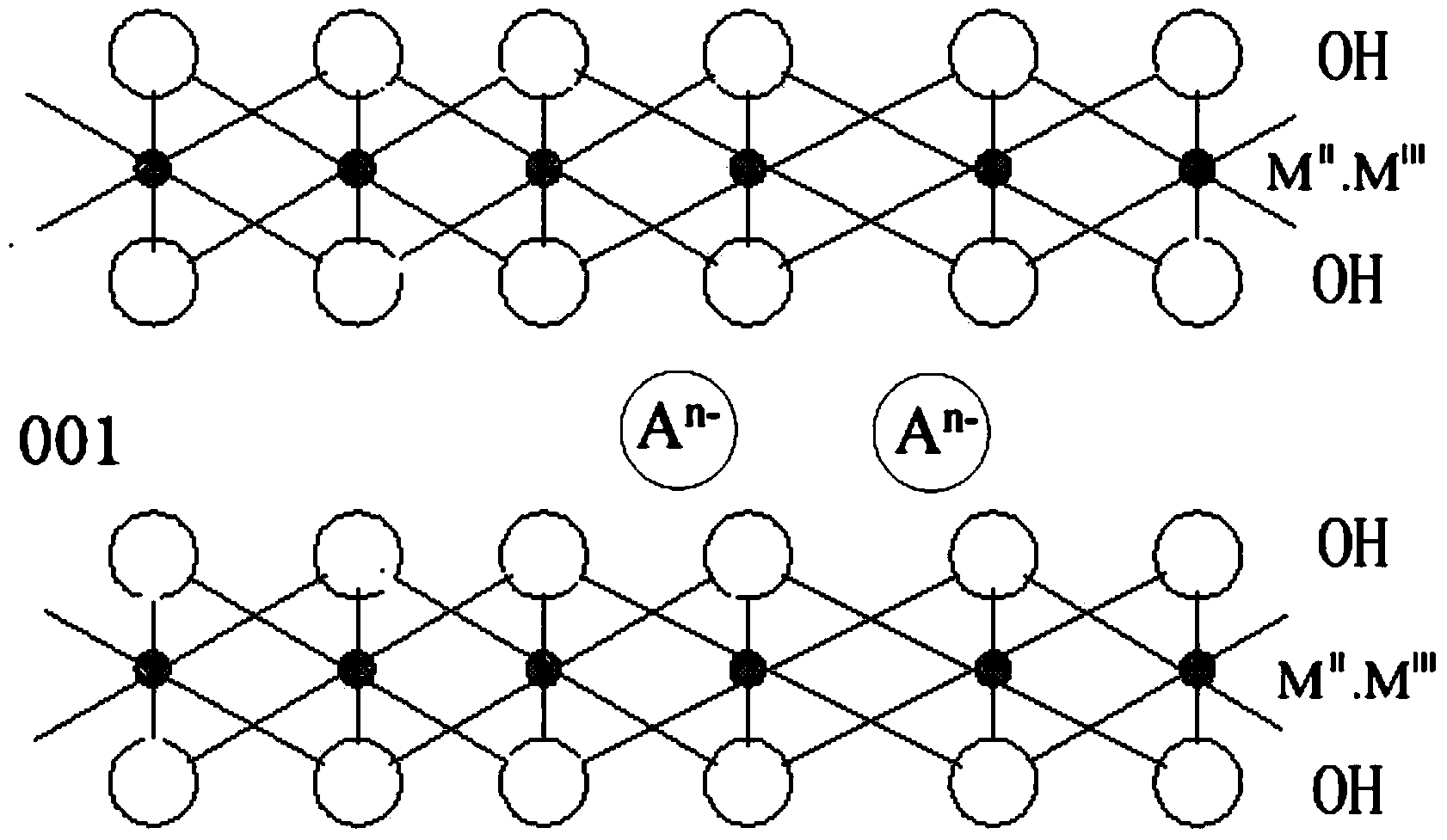

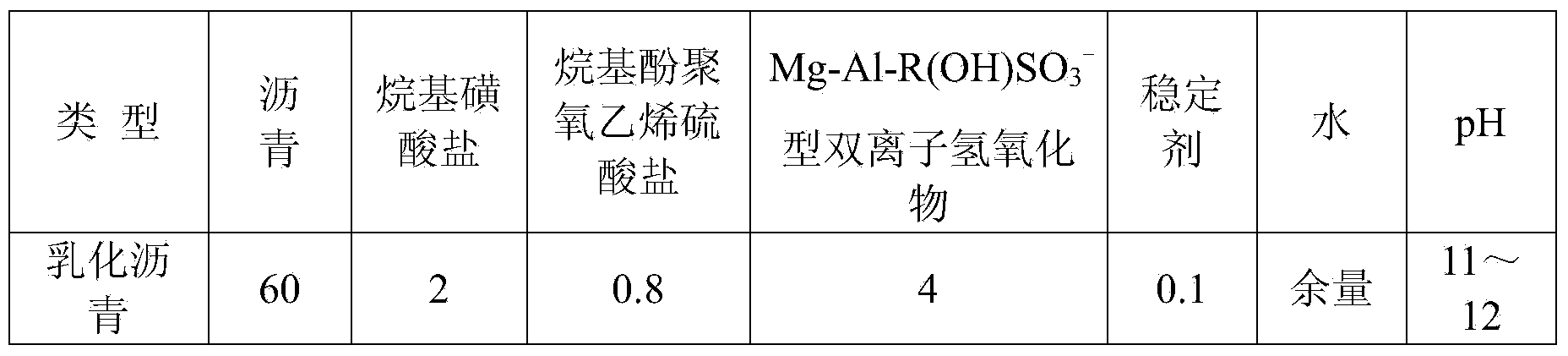

[0061]In this example, the anionic emulsified asphalt is manufactured by emulsification process using 90# heavy traffic road petroleum asphalt, sodium alkyl sulfonate and alkylphenol polyoxyethylene sulfate with an average molecular weight of 400-500, cellulose ether stabilizer, and water , use sodium hydroxide NaOH to adjust the pH to 11-12, then add Mg-Al-R(OH)SO to the prepared anionic emulsified asphalt 3 - Type double ion hydroxide suspension, its composition and proportioning ratio are as shown in Table 2.

[0062] Table 2 Composition and ratio of emuls...

Embodiment 3

[0068] A kind of hydrophobic cement emulsified asphalt mortar in this example is composed of anionic emulsified asphalt, double ion hydroxide emulsified asphalt, dry material and an appropriate amount of polycarboxylic acid superplasticizer and silicone emulsion defoamer and other components , its composition and ratio are shown in Table 6, and the composition and ratio of the dry material are shown in Table 3; the cement emulsified asphalt mortar is mixed by a two-component feeding method.

[0069] In this embodiment, the emulsified asphalt used for mixing mortar is a mixed emulsified asphalt formed after premixing of anionic emulsified asphalt and double ion emulsified asphalt in the factory. The composition of the anionic emulsified asphalt and double ion hydroxide emulsified asphalt The matching ratio is shown in Table 4.

[0070] Table 4 Composition and ratio of emulsified asphalt used in Example 3 (kg)

[0071]

[0072] Table 5 Composition and ratio of a hydrophobic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com