Transformer substation cooperative intelligent inspection system and application method thereof

An intelligent inspection and substation technology, applied in the field of substation inspection, can solve the problems of monitoring dead ends, high precision, poor real-time performance, etc., and achieve the effect of accurate inspection and efficient substation operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

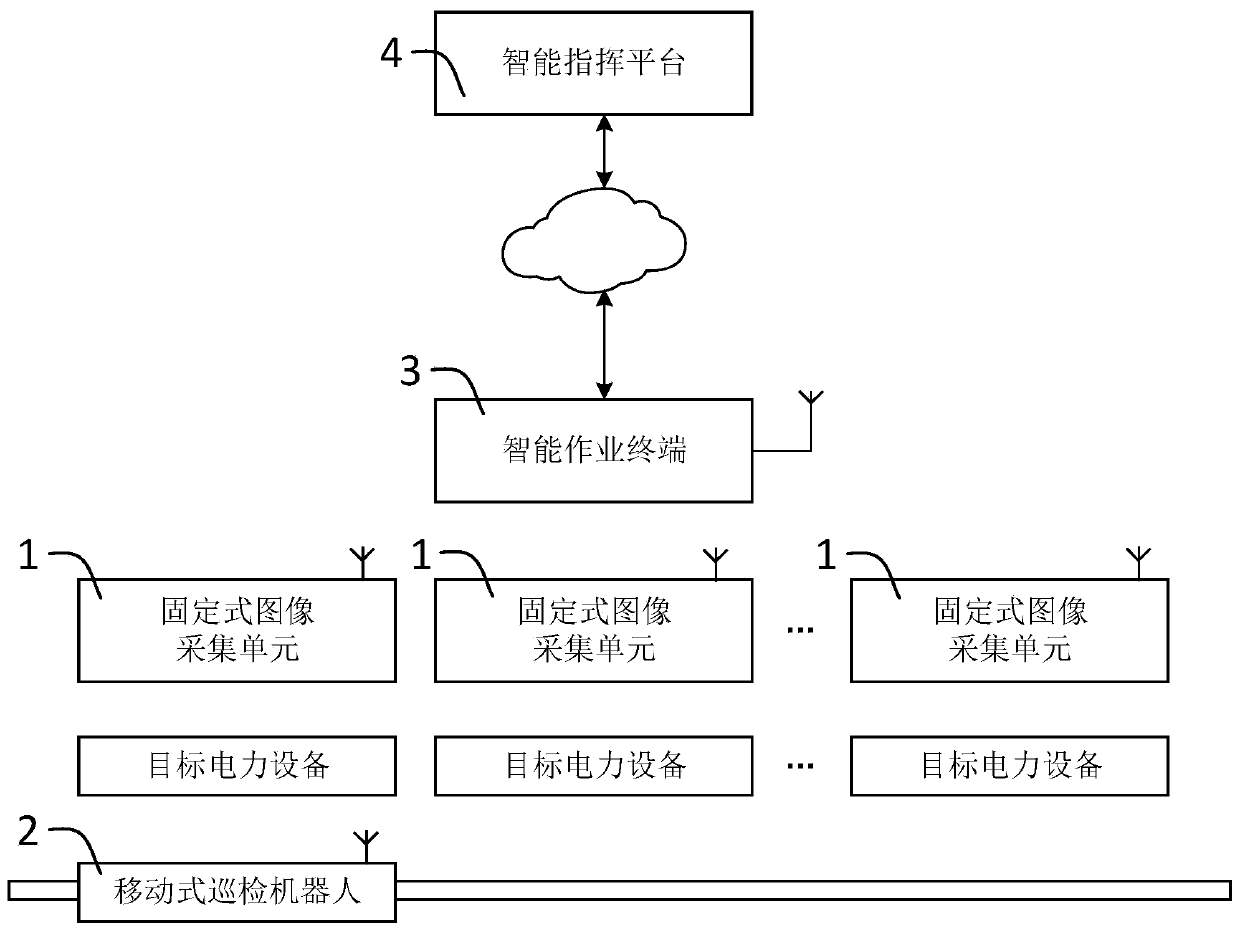

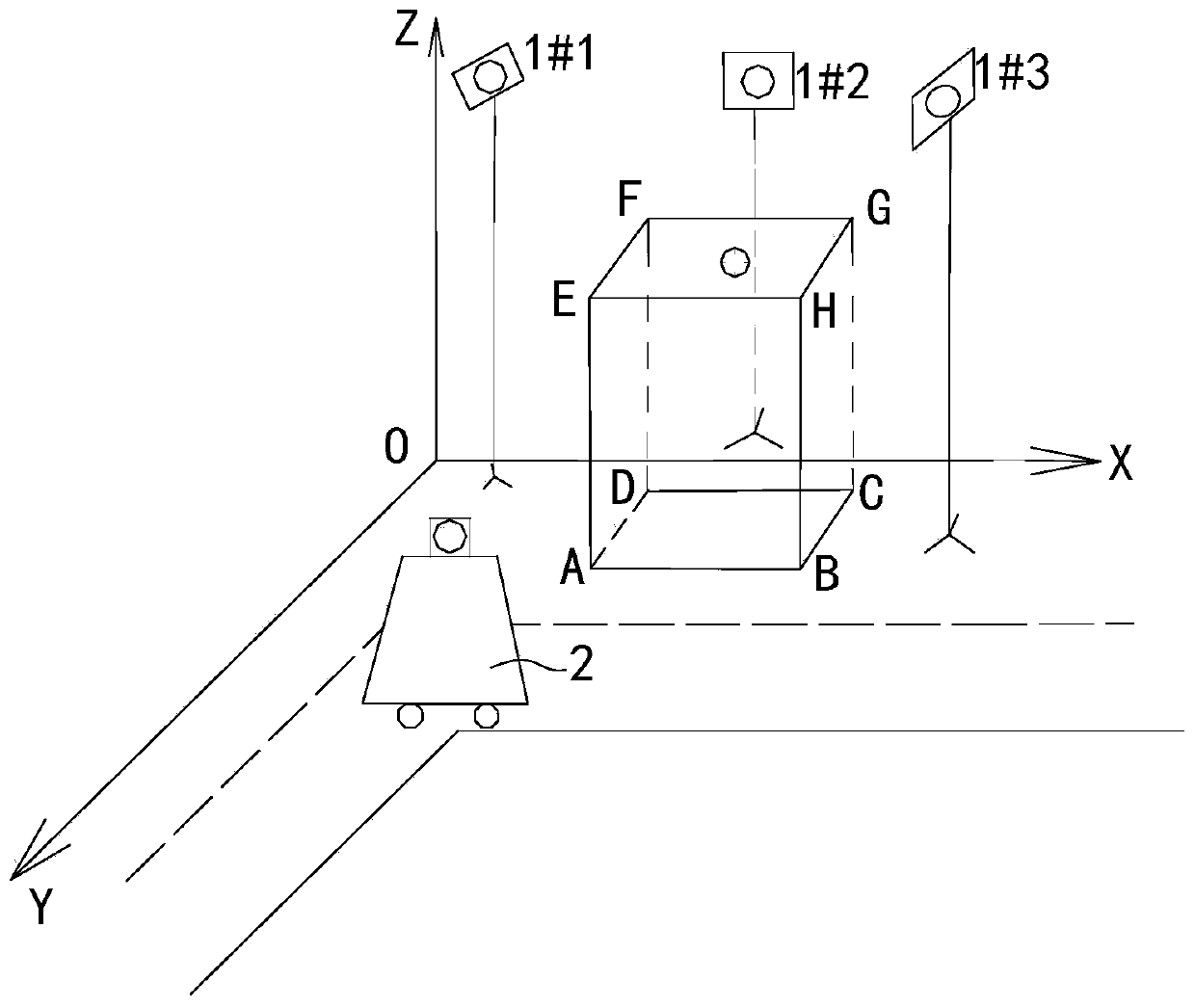

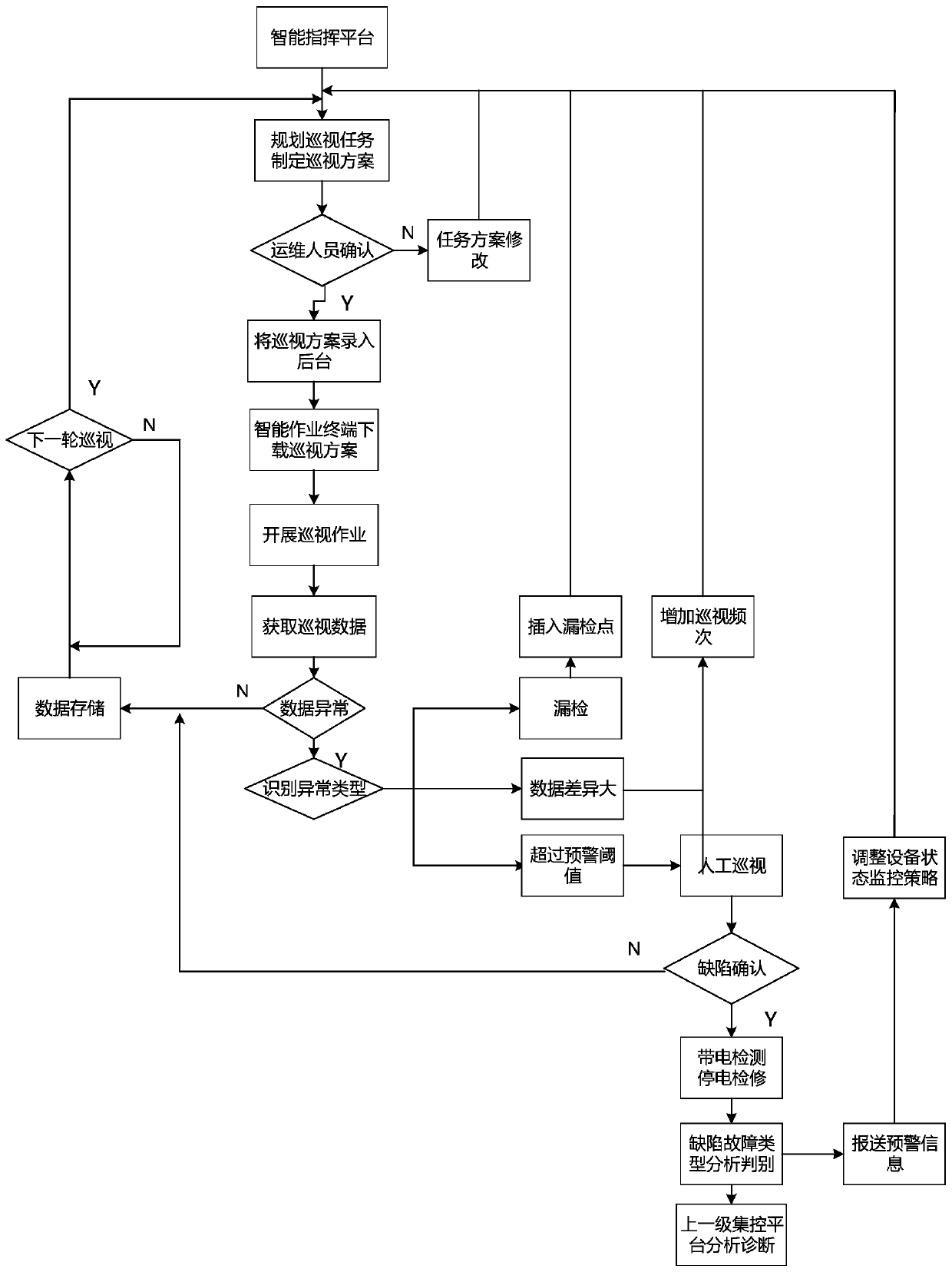

[0030] like figure 1 and figure 2 As shown, the substation cooperative intelligent inspection system of this embodiment includes a fixed image acquisition unit 1, a mobile inspection robot 2 and an intelligent operation terminal 3, and the fixed image acquisition unit 1 and the mobile inspection robot 2 are respectively connected with the intelligent operation The terminal 3 is connected, assuming that the target power equipment is a cube structure, the bottom surface of the cube is a quadrilateral ABCD, the top surface is a quadrilateral FHEF, and the vertices of the quadrilateral ABCD and the quadrilateral FHEF correspond one-to-one, then the target power equipment AEFD surface, FDCG surface, BCGH surface and EFGH surface are located in the monitoring area of the fixed image acquisition unit 1, and the ABHE surface of the target power equipment is located on the side of the walking track of the mobile inspection robot 2. Both the fixed image acquisition unit 1 and the mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com