Wire clamp mounting tool and intelligent equipment

A technology for installing tools and wire clips, which is applied to overhead lines/cable equipment, etc., can solve the problems of labor-intensive operation and danger of connecting and draining lines, and achieves the effects of compact structure, prevention of electric shock, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

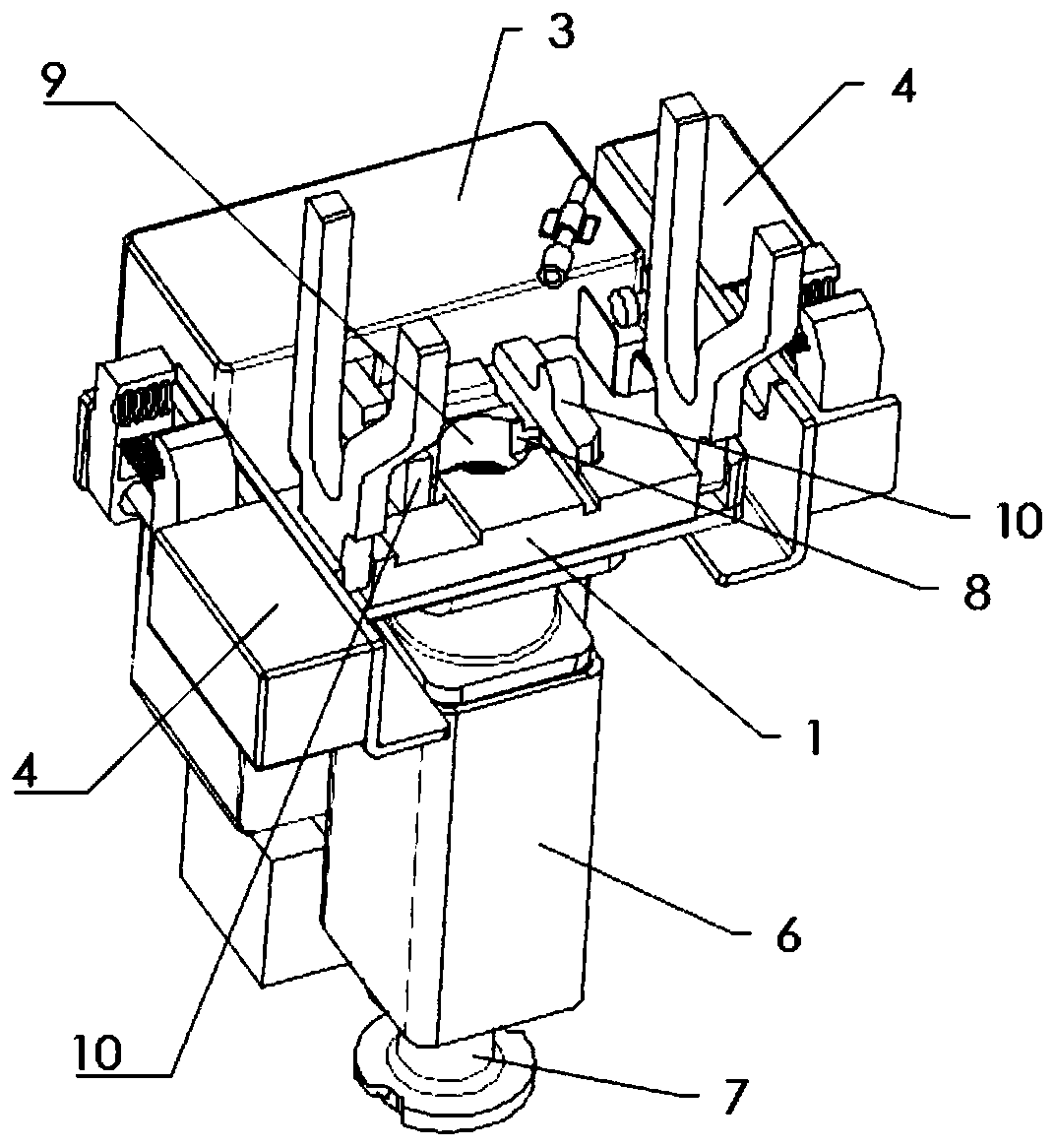

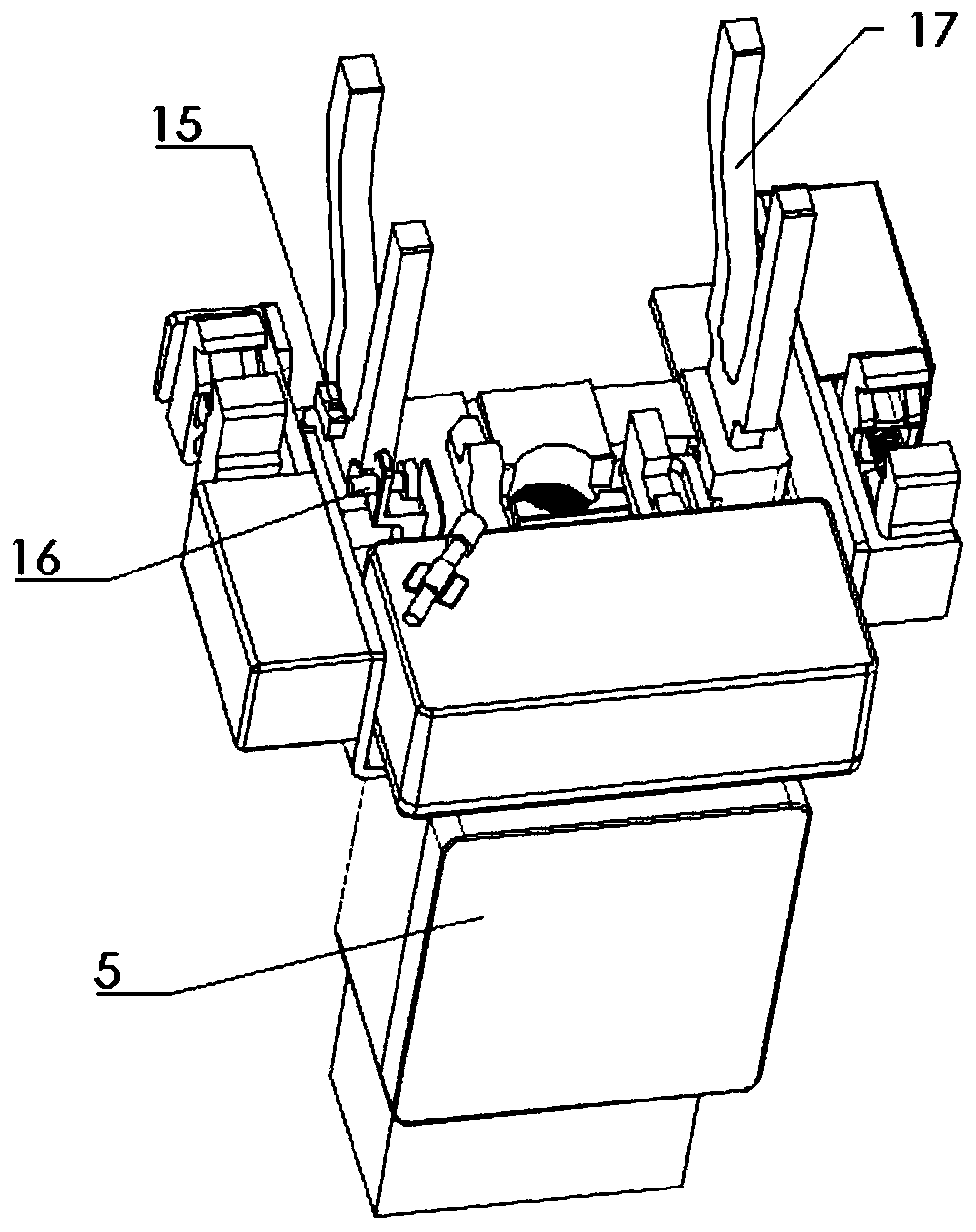

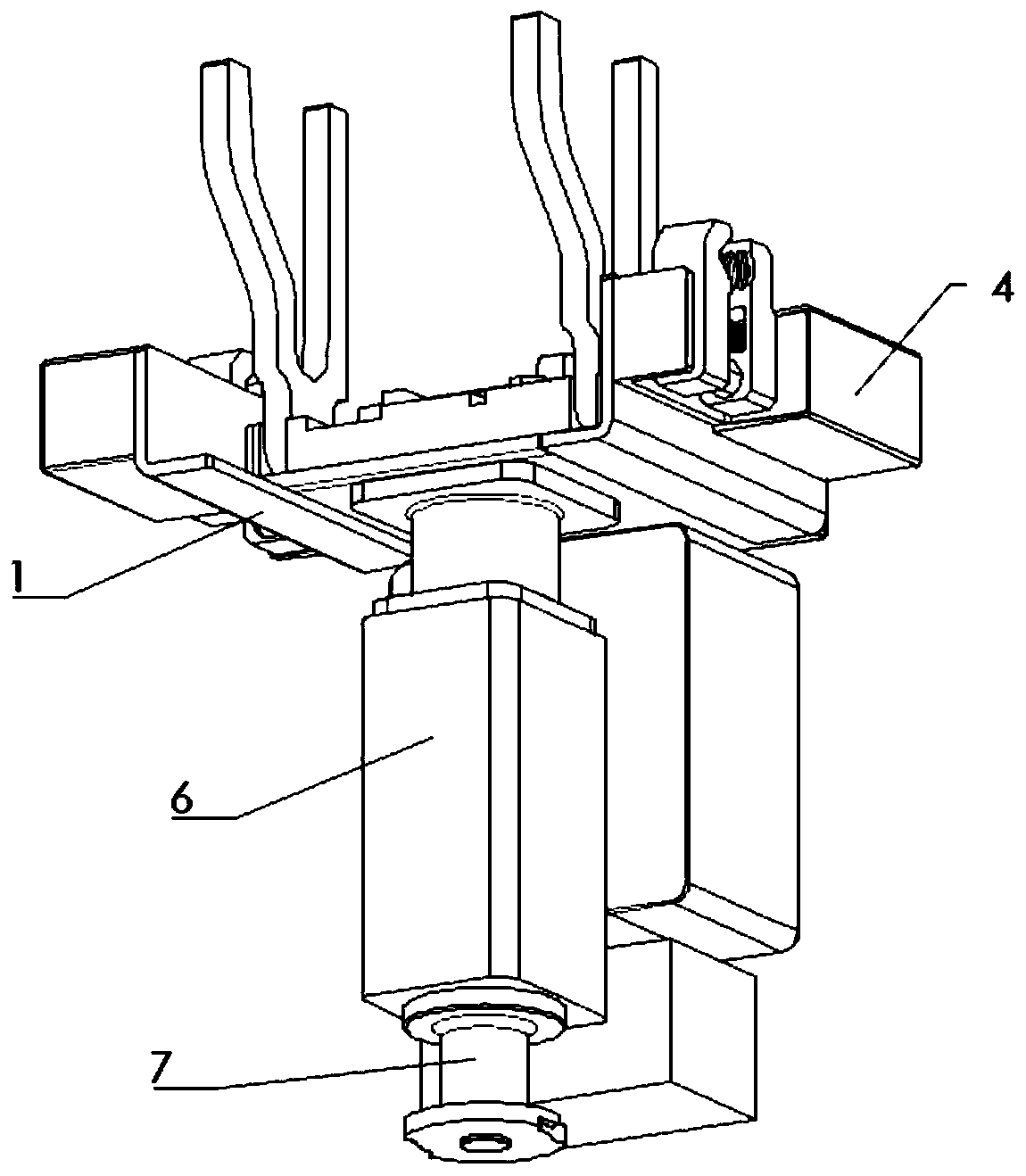

[0036] The clamp installation tool in this embodiment, such as figure 1 - Figure 7 As shown, it includes a frame body 1, a clamping mechanism 3, the wire locking mechanism 4, a controller 5, a wire driving mechanism and an induction component.

[0037]The frame body 1 is installed on the moving arm, and the clamping mechanism 3 , the wiring mechanism 2 and the controller 5 are installed on the frame body 1 to provide support for the clamping mechanism 3 , the wiring mechanism 2 and the controller 5 . The rack body 1 has a placement portion for placing the wiring mechanism 2 . In this embodiment, the placement part is located at the middle of the frame body 1, and the wiring driving mechanism is located at the lower side of the placement part. Therefore, in order to ensure that the placement position of the wiring mechanism 2 is relatively accurate, the tightening part 23 is connected to the wiring driving mechanism, and the placement part has a groove 8 for positioning the ...

Embodiment 2

[0053] The smart equipment in this embodiment has the wire clamp installation tool in Embodiment 1, and a moving arm for installing the wire clamp installation tool. When the intelligent device drives the live connection of the drain wire, first install the wiring mechanism 2 on the placement part of the frame body 1. The way to install the wiring mechanism 2 can be manually placed, or it can be taken by a manipulator or the like, and then placed by a manipulator. The way of taking and placing is more automated. Then, the drain wire 25 and the main wire 24 are installed in the wiring mechanism 2 and the wire locking mechanism 4 successively by moving the movable arm. After the drain wire 25 and the main wire 24 are electrically connected, the wire locking mechanism 4 unclamps the main wire 24 and After the drain wire 25 and the clamping mechanism 3 loosen the wiring mechanism 2, the clamp installation tool moves away from the position of the wiring mechanism 2 to complete a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com