Industrial automatic liquid stirring and conveying device

An industrial automation and conveying device technology, which is applied in mixers with rotating mixing devices, transportation and packaging, mixer accessories, etc., can solve the problems of reduced motor drive efficiency and idling of mixing devices, and achieves improved ease of use and improved work. Efficiency, avoid the effect of irregular swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

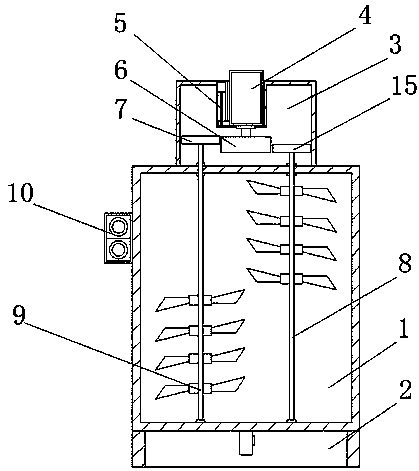

[0021] Embodiment 1: An industrial automatic liquid stirring and conveying device, comprising a stirring box body 1, a motor 4 and a screw stepping motor 5, the bottom end of the stirring box body 1 is fixedly installed with a base 2, and the stirring box body 1 An operation button 10 is fixedly installed at the middle position of the outer side wall.

Embodiment 2

[0022] Embodiment 2: Stirring device is fixedly installed in the inside of stirring box casing 1, and stirring device comprises fixed box 3, motor 4, screw mandrel stepping motor 5, first gear 6, second gear 7, first transmission rod 8, The second transmission rod 9 and the third gear 15, the top of the mixing box casing 1 is fixedly equipped with a fixed box 3, and the inner top of the fixed box 3 is fixed with a screw stepping motor 5 by bolts, and the screw stepping motor 5 The model is FSL40, and the slider of the screw stepping motor 5 is fixed with a motor 4 by bolts, the model of the motor 4 is YS90-2, the input end of the motor 4 is electrically connected with the output end of the operation button 10, and the operation button The input end of 10 is electrically connected to the external power supply, the output end of the motor 4 is fixedly installed with the first gear 6, and the inner two sides of the mixing box body 1 are respectively fixedly installed with the firs...

Embodiment 3

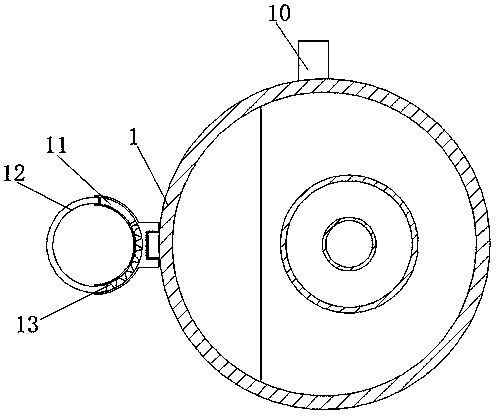

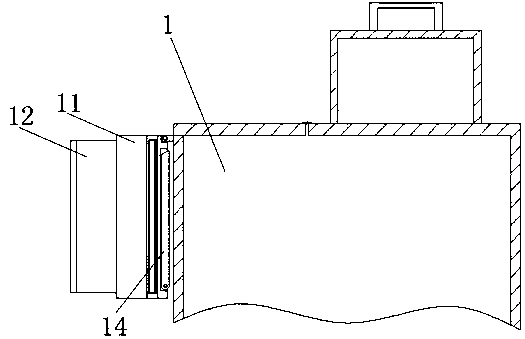

[0023] Embodiment 3: The outside of the mixing box body 1 is provided with a delivery pipe fixing device, the delivery pipeline fixing device includes a support seat 11, a limit rod 12, a spring 13 and a support rod 14, and the front end of the mixing box box body 1 is connected to the support by a rotating shaft. The seat 11 is fixedly connected, and the inside of the support seat 11 is provided with a setting groove, and the inside of the setting groove is fixedly installed with a support rod 14 through a rotating shaft. The side of the setting groove is designed to be inclined, and the fixed end of the support rod 14 is designed to be inclined. , the inclination angles of the two sets of inclined designs are the same, through this design, the setting groove can form a limit effect on the support rod 14, and when the support rod 14 contacts the side wall of the mixing box body 1, the mixing box body 1 can pass through The support rod 14 and the support seat 11 form a relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com