Cleaning frame applied to solar silicon wafer

A technology for solar silicon wafers and cleaning racks, which is applied in the directions of cleaning methods using liquids, cleaning methods and utensils, sustainable manufacturing/processing, etc., which can solve the problem of low cleaning degree of silicon wafers, affecting the use of silicon wafers, and poor fixing effect of silicon wafers and other problems, to achieve the effect of enhanced cleaning effect, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

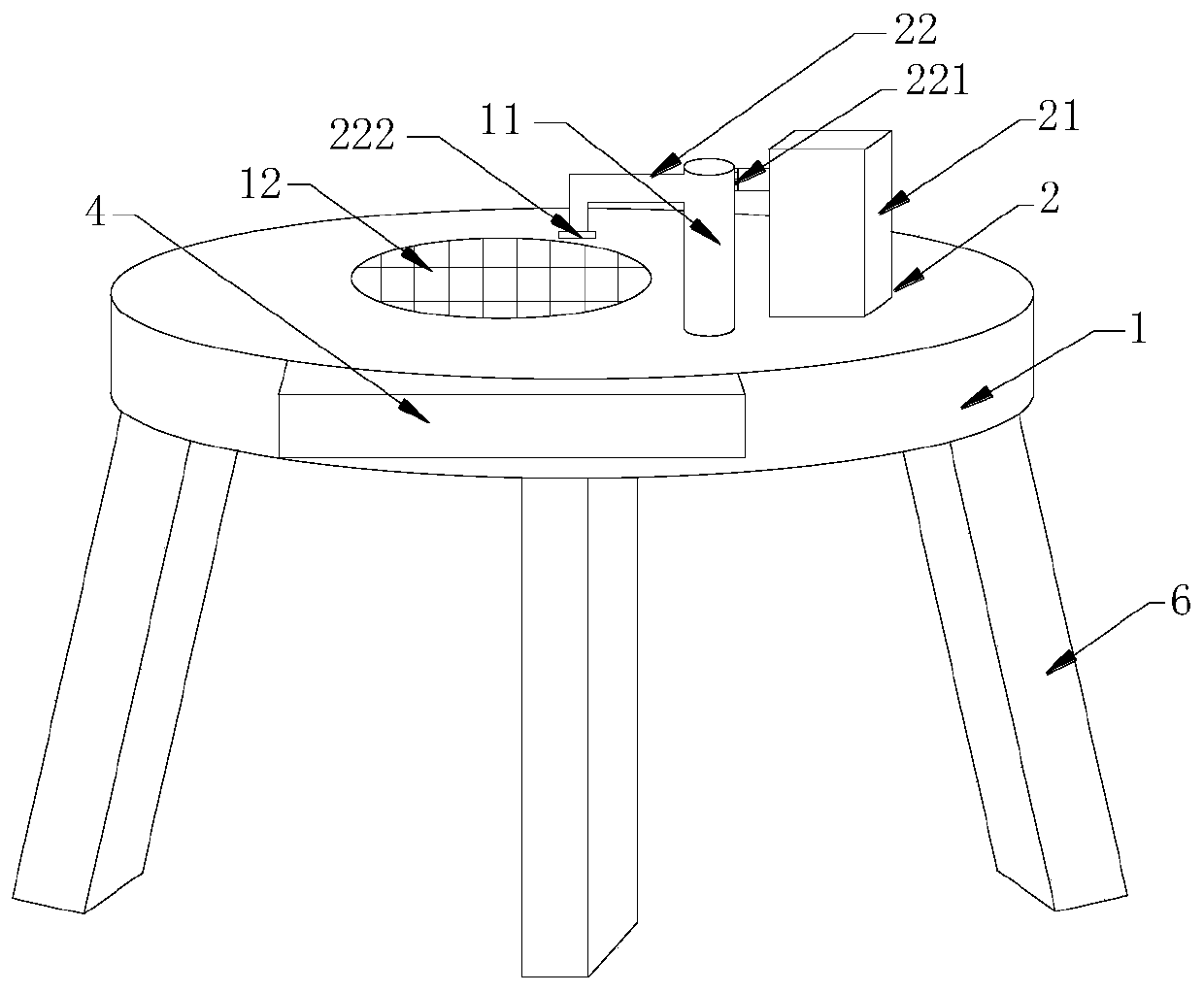

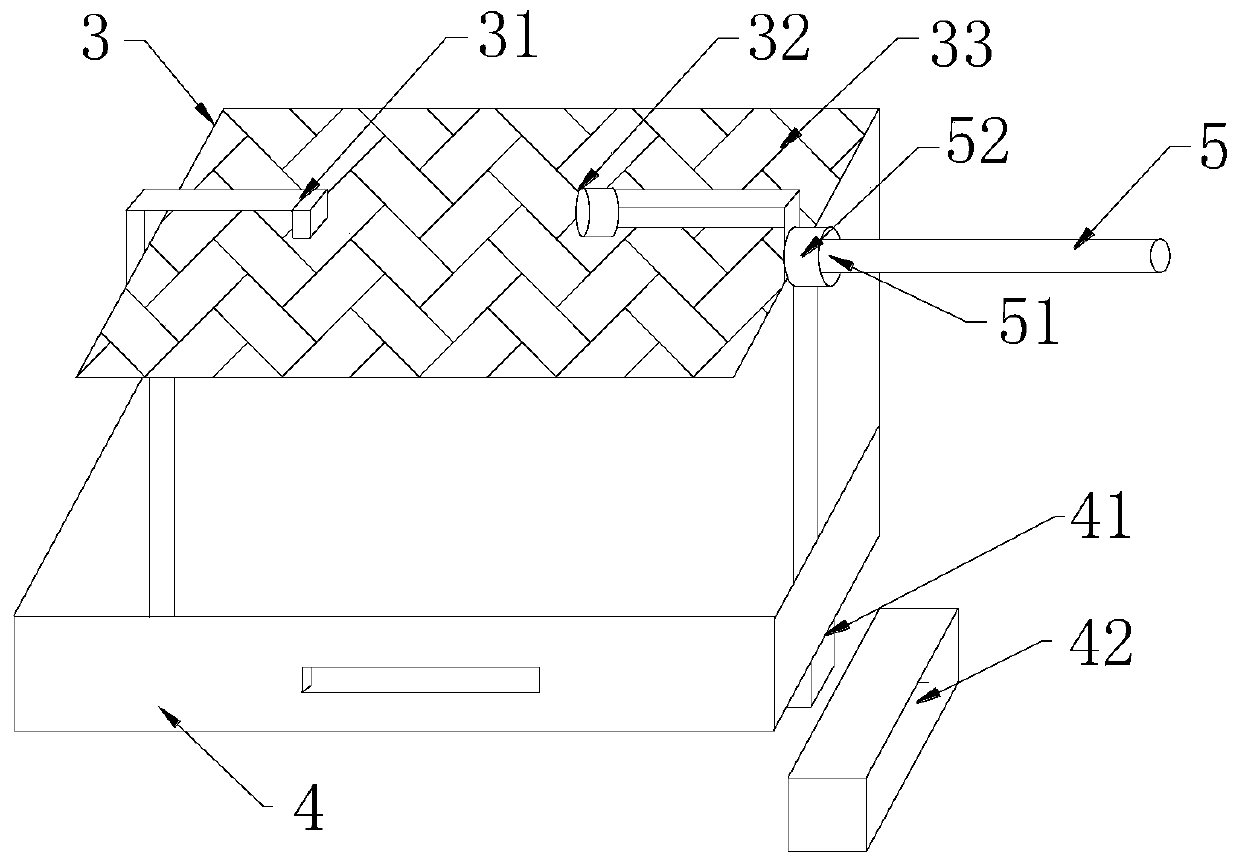

[0021] Example: such as Figure 1-2 As shown, a cleaning rack applied to solar silicon wafers includes a working platform 1, a cleaning assembly 2 positioned at the working platform 1, and a fixed frame 3 arranged inside the working platform 1; the working platform 1 includes a spray gun bar 11, a spraying Area 12; the spray gun bar 11 is arranged on the surface of the working platform 1, the spray area 12 is located at one side of the spray gun bar 11, and the spray area 12 is composed of several spray through holes, and the cleaning assembly 2 includes a water tank 21 and a spray gun 22; The water tank 21 is located on the surface of the working platform 1 and is on the same horizontal line as the spray gun rod 11. The spray gun 22 is located on the top of the spray gun rod 11. The spray gun 22 is on the same vertical line as the spraying area 12 on the surface of the working platform 1. The bottom of the spray gun 22 passes The water pipe is fixedly connected to the water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com