Automatic riveting machine for advertising traffic sign board

A sign board and riveting machine technology, applied in the field of riveting, can solve the problems of relative stress conflict of position deviation plates, reduce the production and forming time of the sign plate, and separate and damage the sign plate plate, so as to improve the forming time, improve the riveting quality and improve the efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

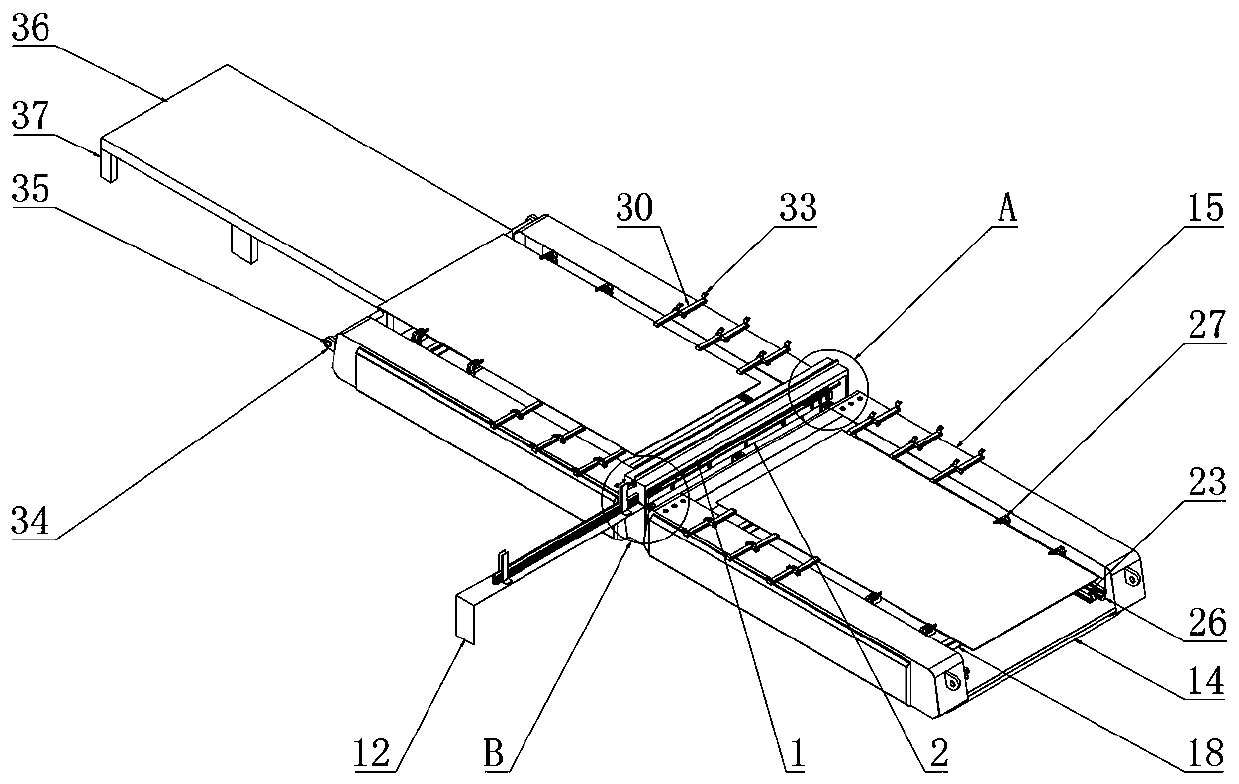

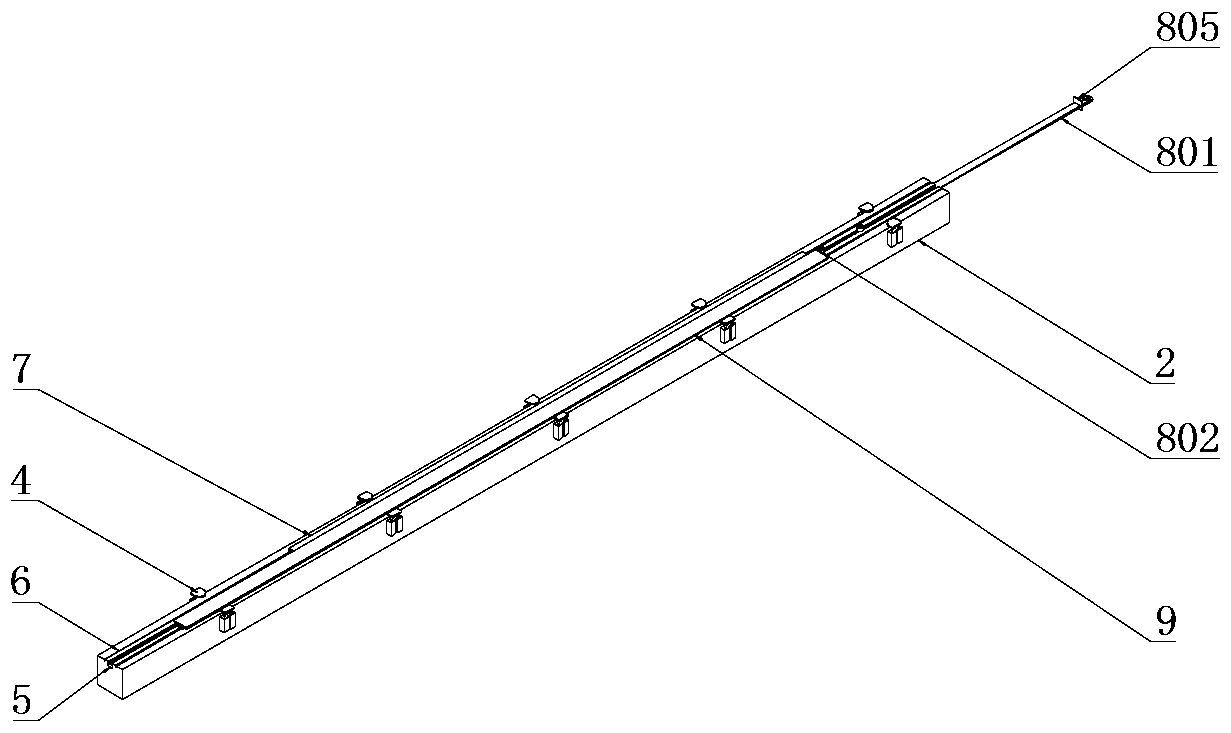

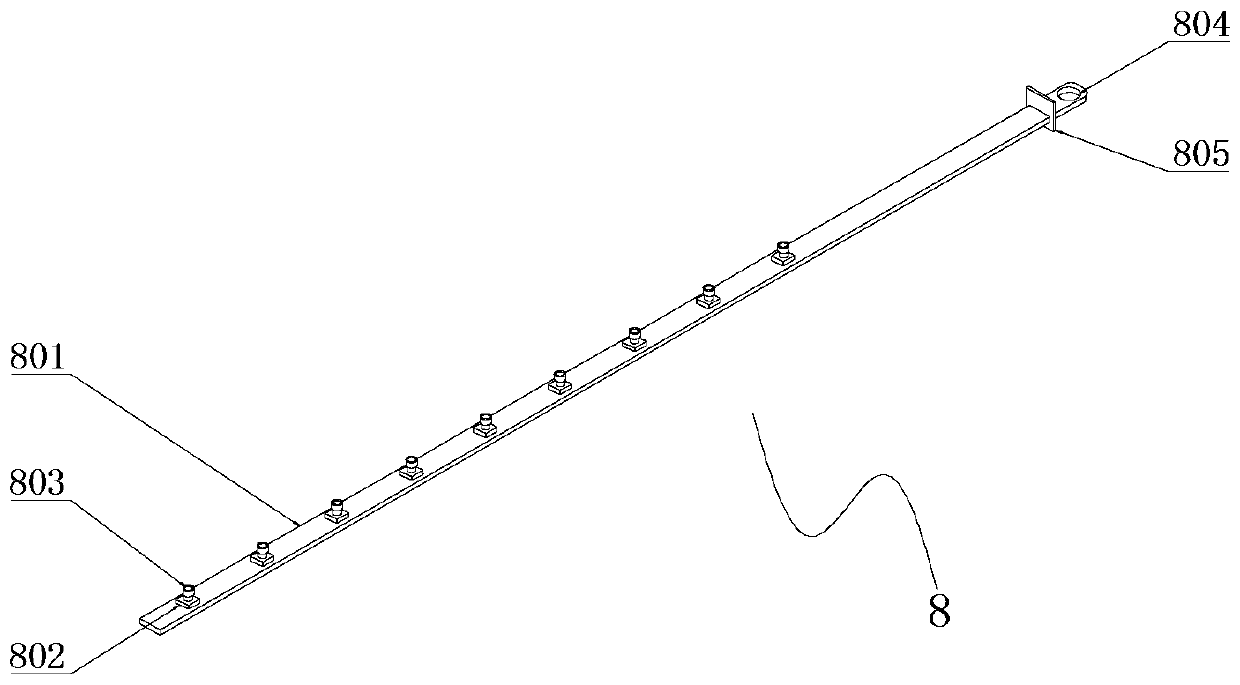

[0034] Example: such as Figure 1-9As shown, the present invention provides a technical solution, an automatic riveting machine for advertising traffic signs, including a fixed frame 1, a buffer installation rod 2 is arranged in the middle of the inner side of the fixed frame 1, and a supporting pneumatic cylinder 3 is installed at the bottom end of the inner side of the fixed frame 1 , the top of the supporting pneumatic cylinder 3 is fixedly connected with the buffer installation rod 2, which is convenient for pushing the buffer installation rod 2 upward to squeeze the inner top of the fixed frame 1, and the two sides of the buffer installation rod 2 are symmetrically installed with fixing clips 4, and the three fixing clips 4 form a group , can be installed with three different corner materials, the middle part of the top of the buffer installation rod 2 is provided with an installation groove 5, and the top of the buffer installation rod 2 is provided with an auxiliary groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com