Multi-slider electric precise die-casting machine

A precision die-casting, multi-slider technology, applied in the field of workpiece die-casting equipment, to achieve the effect of easy operation, more efficient equipment, and stable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

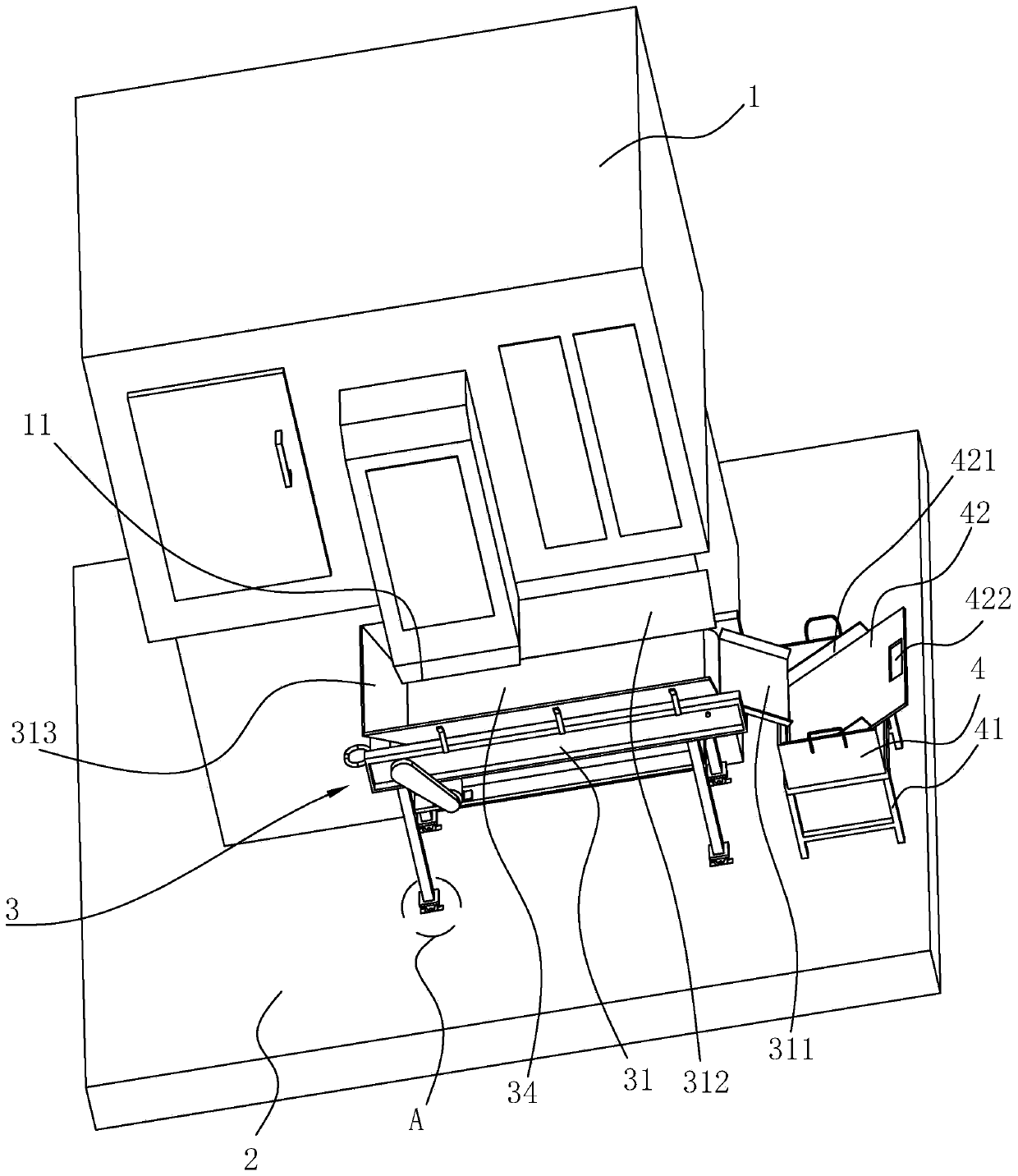

[0040] A multi-slider electric precision die-casting machine, refer to figure 1 , which includes a frame 1 and a discharge port 11 located on the frame 1, the direction of the discharge port 11 is downward; the frame 1 is placed on the ground 2, a conveying mechanism 3 is arranged on the ground 2, and the workpiece is placed in the die-casting machine After being processed, it falls onto the conveying mechanism 3 through the discharge port 11. Through the height of the conveying mechanism 3, the workpiece falls into sections, and the damage caused by the collision of the workpiece is repaired.

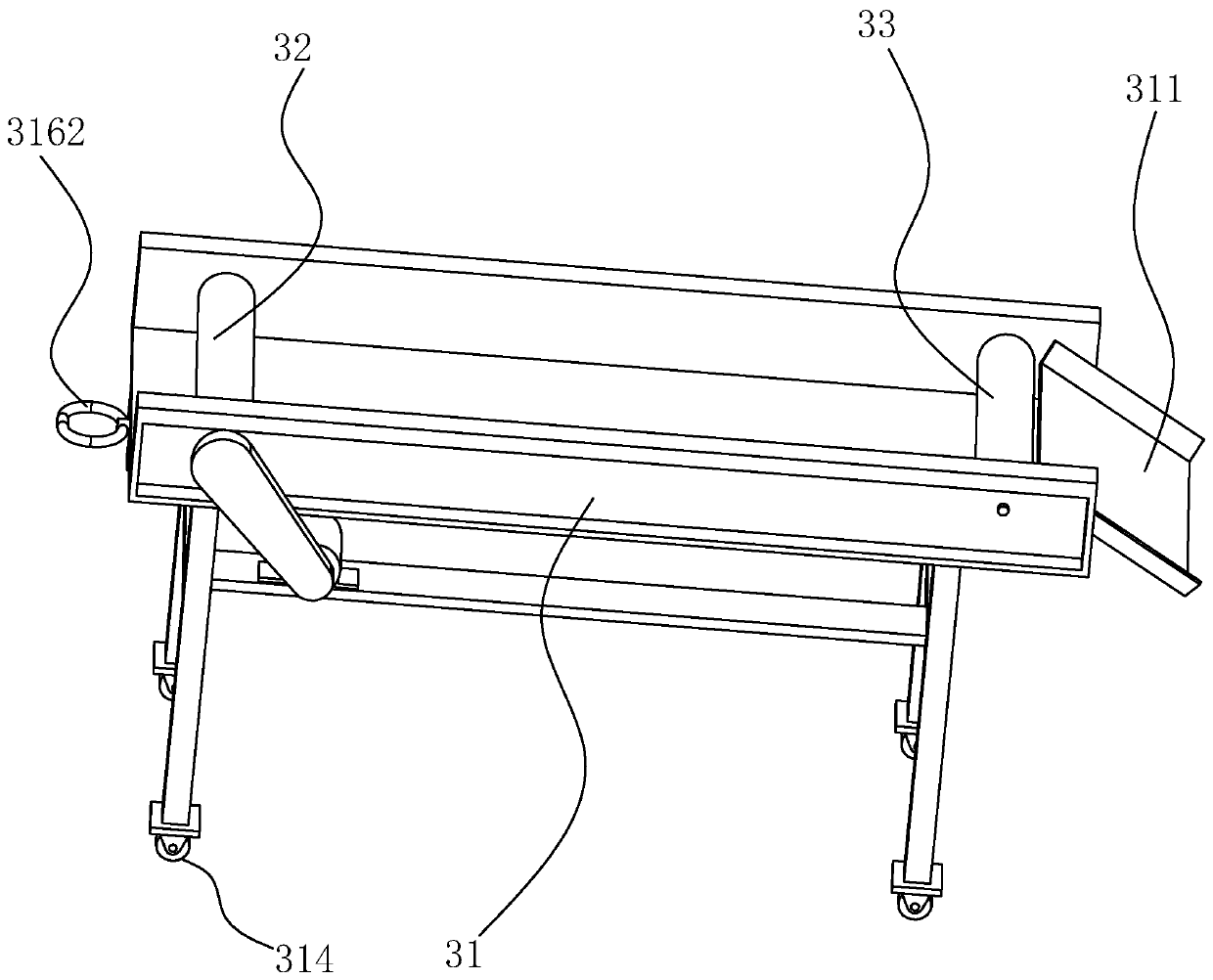

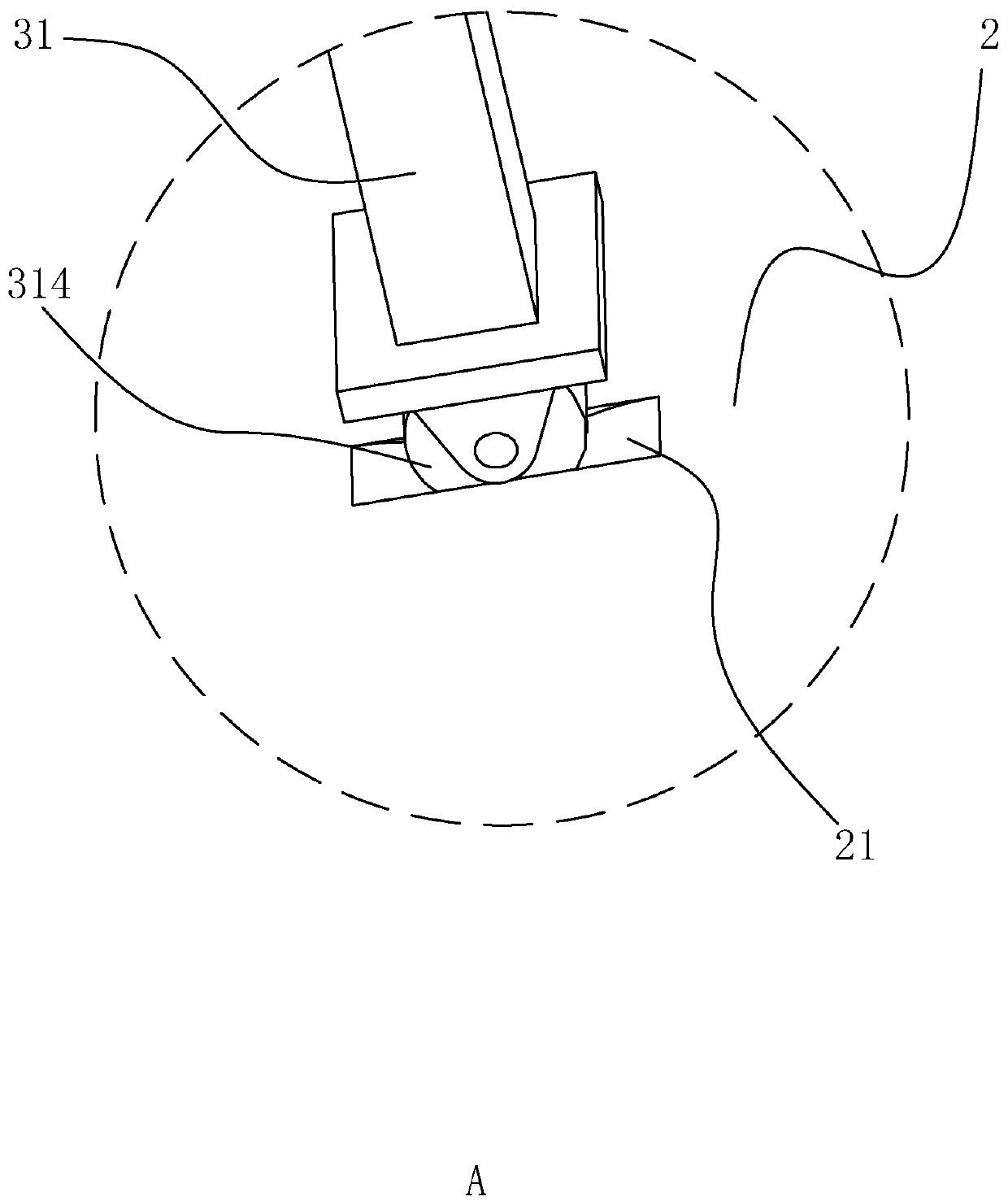

[0041] refer to figure 1 with figure 2The conveying mechanism 3 includes a conveying frame 31, a driving roller 32 rotatably connected to the conveying frame 31, a driven roller 33 rotatably connected to the conveying frame 31, and a conveyor belt 34 sleeved on the driving roller 32 and the driven roller 33 The material of conveyor belt 34 is preferably rubber, and conveyor frame 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com