A kind of organosilicon modified polyether-polycarbonate waterborne polyurethane and preparation method thereof

A water-based polyurethane and polycarbonate technology, applied in the field of silicone-modified polyether-polycarbonate water-based polyurethane and its preparation, can solve the problems of poor water resistance and heat resistance, insufficient mechanical strength, etc., and achieve the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

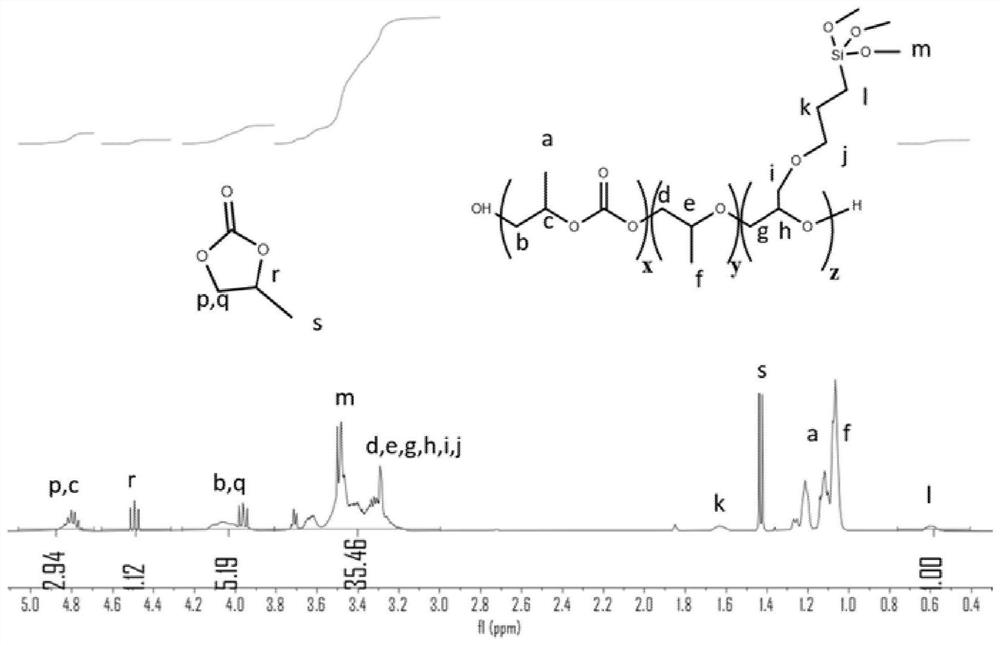

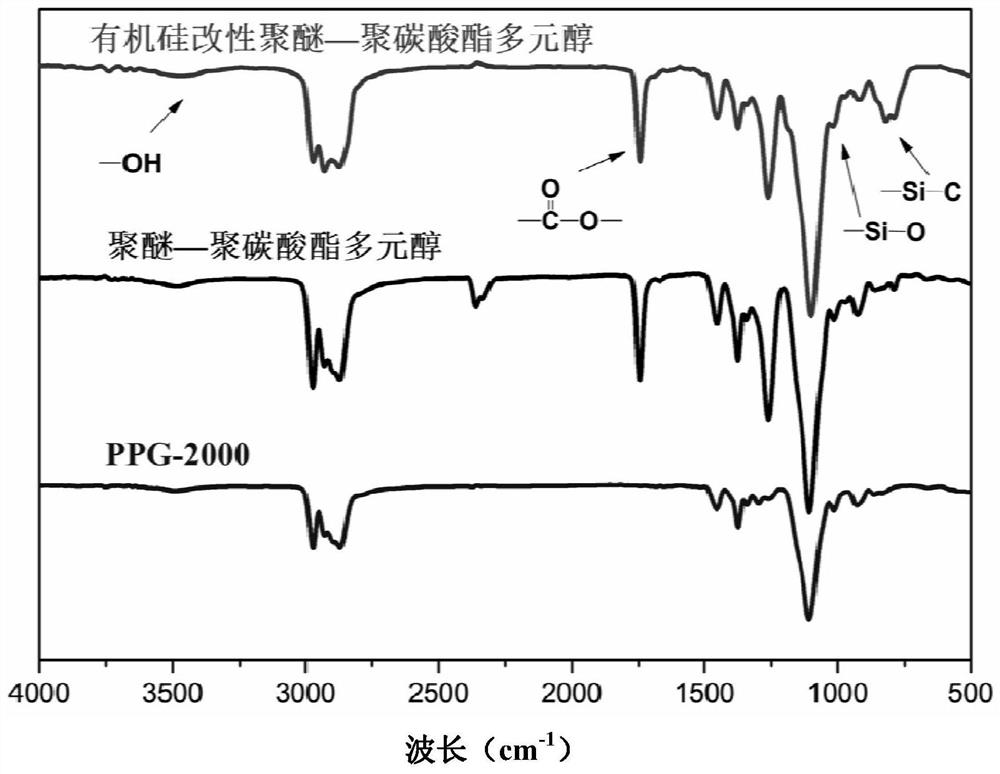

[0088] Step 1: Preparation of silicone-modified polyether-polycarbonate polyol

[0089] Before starting the reaction, a 100 mL stainless steel autoclave was cleaned, and vacuum-dried at 80° C. for 2 h to remove water in the autoclave. Add 34.08g (0.587mol) of propylene oxide, 10.4g (0.044mol) of KH560, 10.0g (0.025mol) of PPG-400 and 20mg of zinc-cobalt double metal cyanide complex into the reactor, and fill it with a small amount of CO 2 and warmed up to 100°C, followed by adjustment of CO 2 Pressure to 5MPa reaction 12h. After the reaction, the reactor was cooled in an ice-water bath, and the gas in the reactor was slowly released at normal temperature. The crude product was dissolved in 20 mL of dichloromethane, and then precipitated in 150 mL of n-hexane to obtain a silicone-modified polyether-polycarbonate polyol.

[0090] After testing, the number average molecular weight of the product is 1500g / mol, the PDI is 1.7, the carbonate content is 13.5 mol%, and the organosi...

Embodiment 2

[0095] Step 1: Preparation of silicone-modified polyether-polycarbonate polyol

[0096] The preparation method is the same as step 1 in Example 1, except that the mass of PPG-400 is changed to 8.1g (0.02mol) to obtain a silicone-modified polyether-polycarbonate polyol with a number average molecular weight of 2200g / mol, PDI It is 2.0, the content of carbonate is 17.1 mol%, and the content of organic silicon segment is 4.1 mol%.

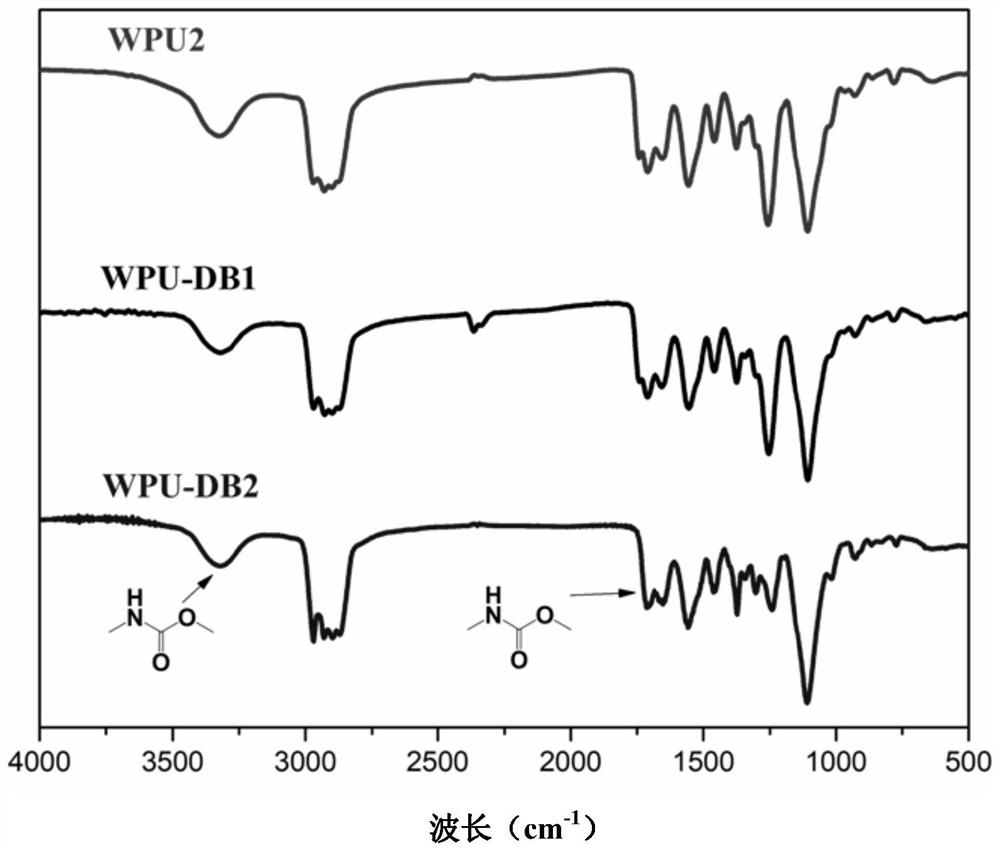

[0097] Step 2: Preparation of silicone-modified polyether-polycarbonate waterborne polyurethane

[0098] In a 250mL four-neck flask, add 10g (0.0045mol) of the silicone-modified polyether-polycarbonate polyol prepared in step 1, 0.79g (0.0056mol) of dimethylol propionic acid and 0.001g of dibutyltin dilaurate Catalyst, after heating up to 80°C, slowly add 5g (0.022mol) isophorone diisocyanate dropwise into the flask, react for 2h after the dropwise addition, cool down to 40°C, add 0.60g triethylamine (0.0056mol), react 0.5h, add 12.0g deionized wate...

Embodiment 3

[0101] Step 1: Preparation of silicone-modified polyether-polycarbonate polyol

[0102] The preparation method is the same as step 1 in Example 1, except that the mass of PPG-400 is changed to 5.9g (0.015mol) to obtain a silicone-modified polyether-polycarbonate polyol with a number average molecular weight of 3100g / mol, PDI 2.2, the carbonate content is 21.9 mol%, and the organosilicon segment content is 4.6 mol%.

[0103] Step 2: Preparation of silicone-modified polyether-polycarbonate waterborne polyurethane

[0104] In a 250mL four-necked flask, add 12g (0.0039mol) of the silicone-modified polyether-polycarbonate polyol prepared in step 1, 0.89g (0.0063mol) of dimethylol propionic acid and 0.001g of dibutyltin dilaurate catalyst After the temperature was raised to 80°C, 5g (0.022mol) of isophorone diisocyanate was slowly added dropwise to the flask. After the dropwise addition, it was reacted for 2 hours, and the temperature was lowered to 40°C. 0.67g (0.0063mol) of triet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com