A prefabricated inline shear wall-prefabricated floor slab system FRP sheet connection structure and method

A technology of FRP sheet and connecting structure, applied in the direction of building structure and construction, can solve the problems of difficult connection performance, poor environmental benefit, low efficiency, etc. Bits and shelving for handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

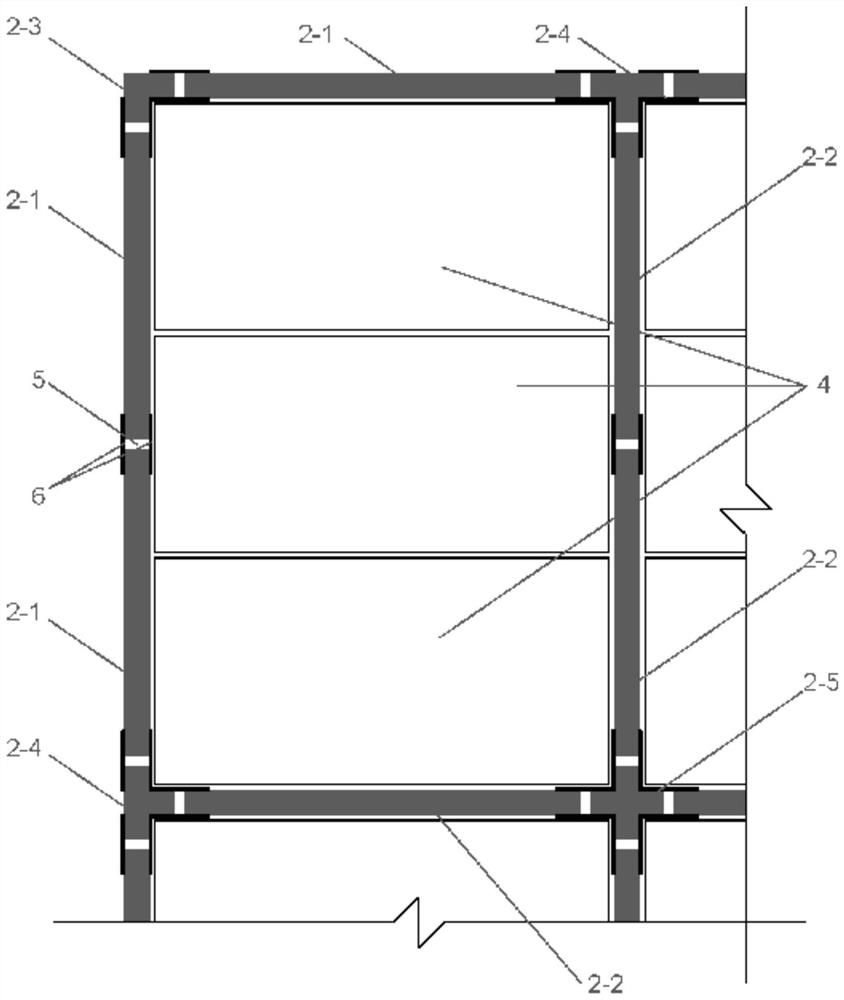

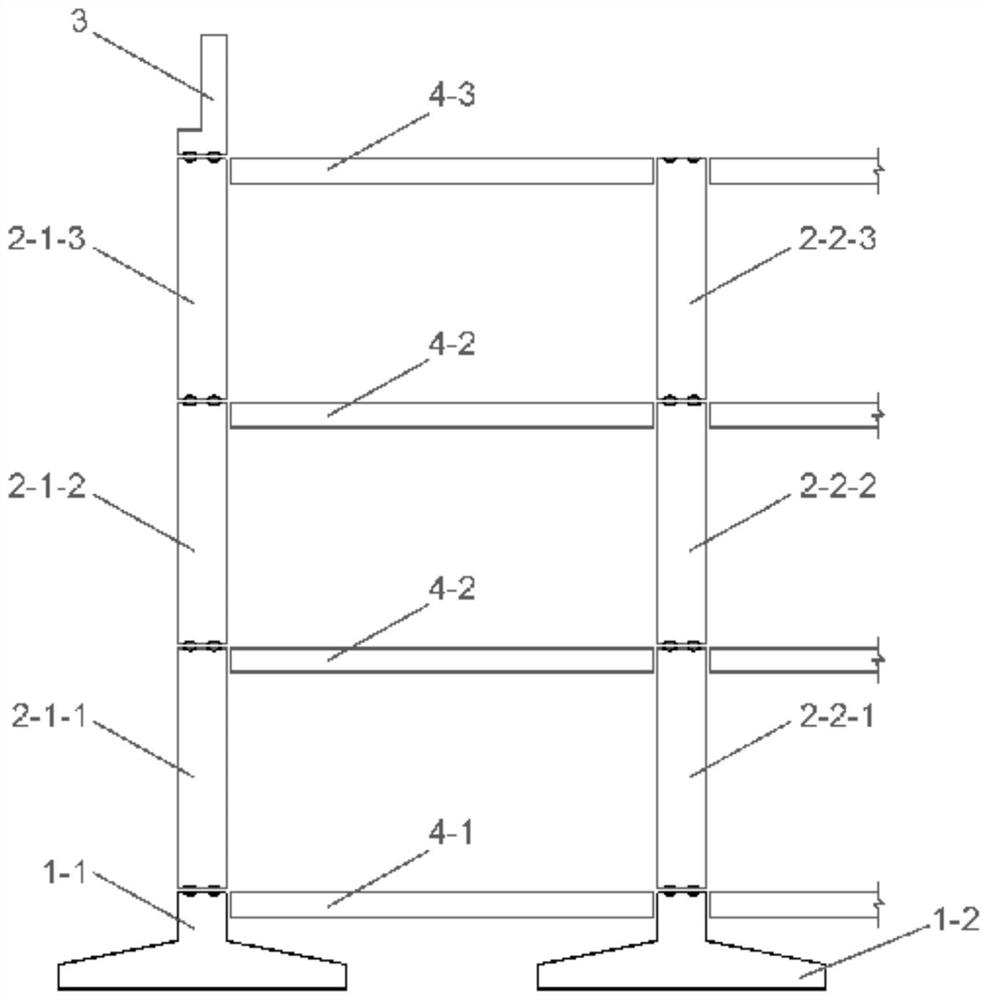

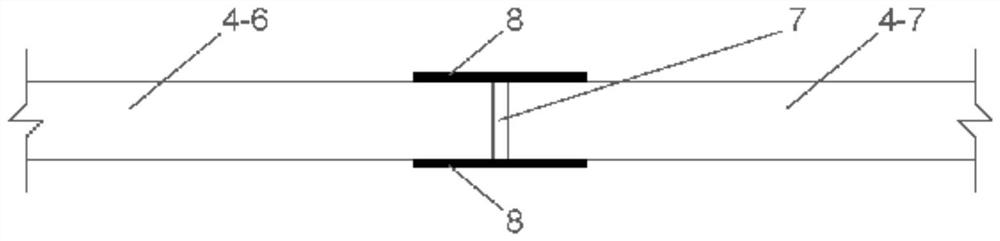

[0044] A prefabricated inline shear wall-prefabricated floor slab system FRP sheet connection structure, including prefabricated foundation, shear wall, parapet 3, floor 4 and other connected objects; these objects are connected by FRP sheet connection structure .

[0045] The foundation is a strip foundation under a conventional wall, including a side foundation 1-1 and an inner foundation 1-2.

[0046] In the horizontal direction, the shear wall includes a side wall 2-1 and an inner wall 2-2, the two adjacent side walls 2-1 of the right-angle structure are transitioned through the L-shaped edge member 2-3, and the T-shaped structure is connected to each other. The two adjacent side walls 2-1 and one inner wall 2-2 are transitioned through T-shaped edge members 2-4, and the four adjacent inner walls 2-2 of the cross structure are transitioned through cross-shaped edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com