Inductor and manufacturing method thereof

A production method and technology of inductance, which is applied in the direction of inductors, circuits, electrical components, etc., can solve the problem that it is difficult to achieve high inductance value and high quality factor at the same time in planar inductance, and achieve the effect of good quality factor and large inductance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

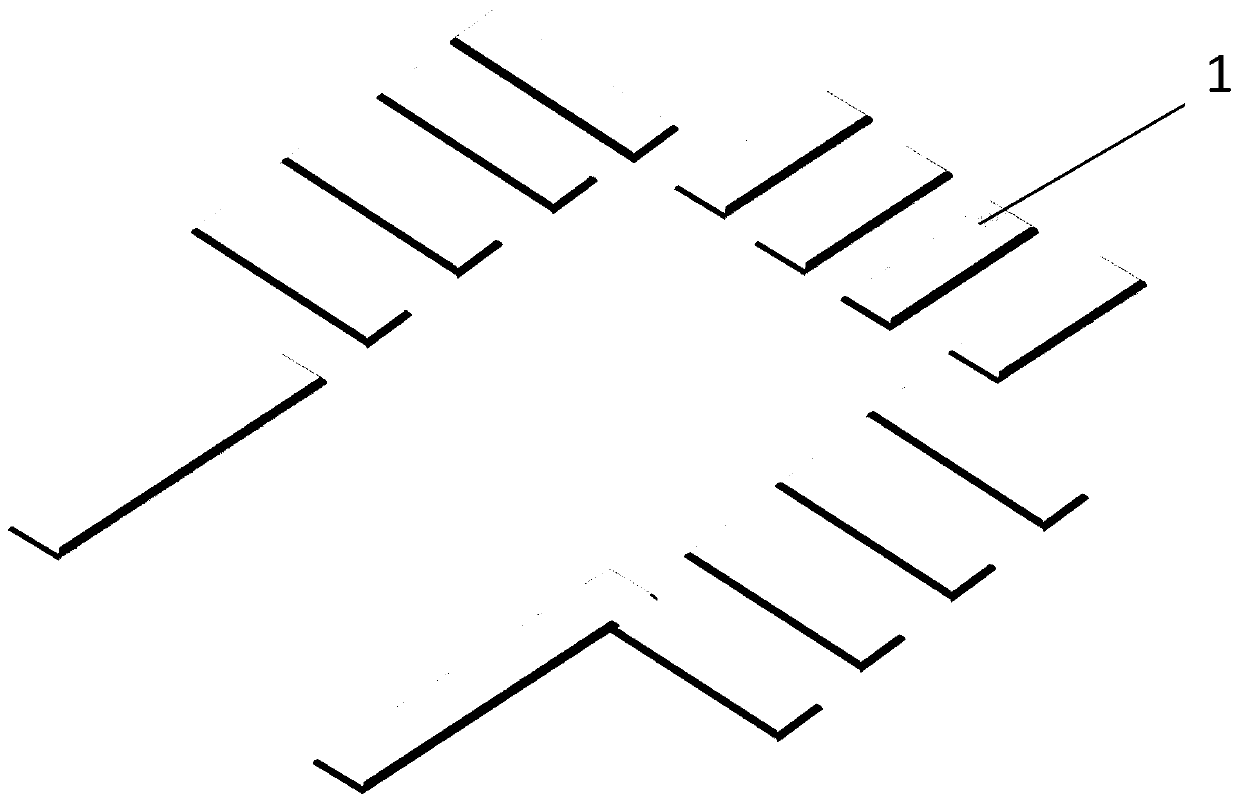

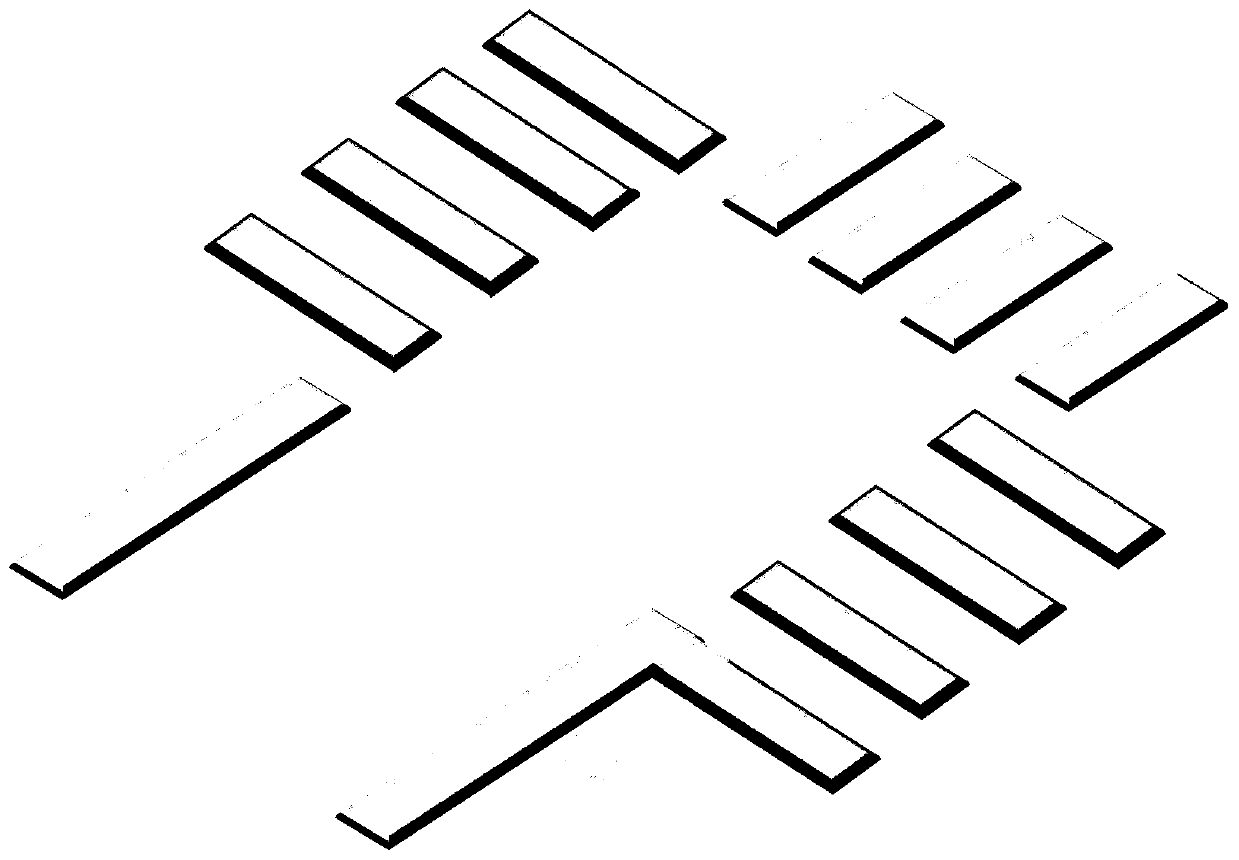

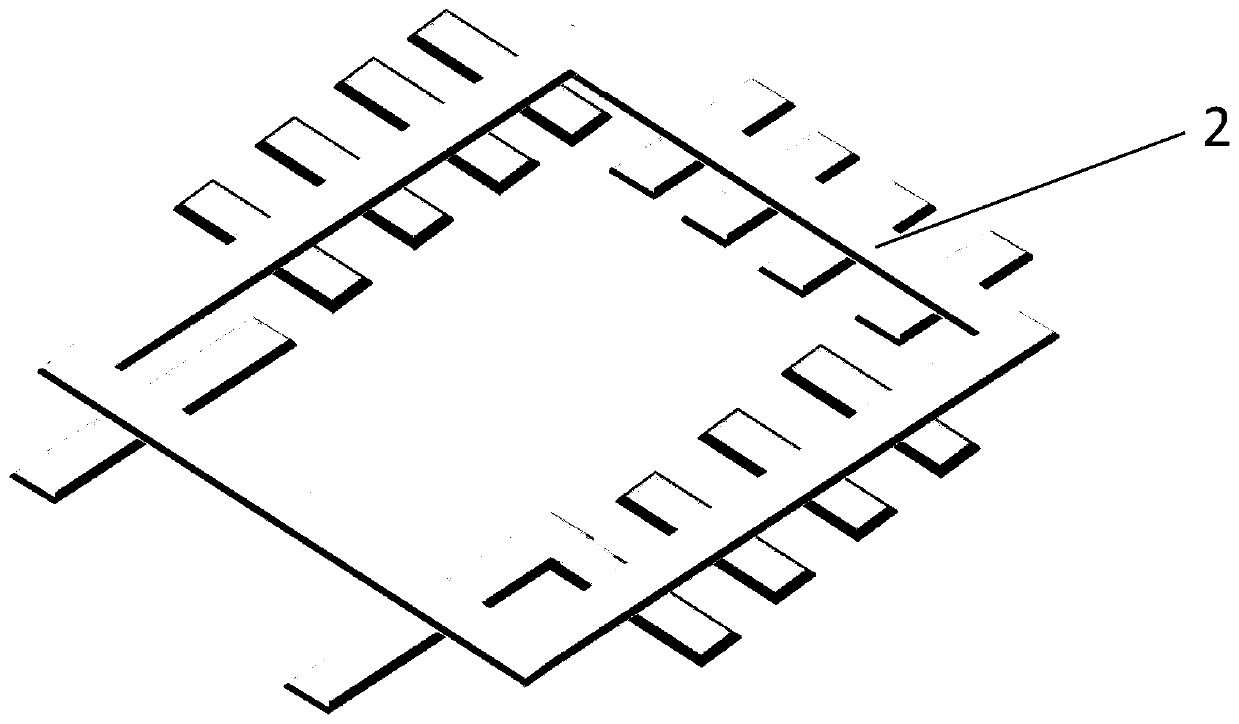

[0037] see Figure 1 to Figure 6 , this embodiment provides a method for manufacturing an inductor, which can generally be manufactured on an epitaxial wafer of a semiconductor device. The method comprises the following steps: depositing the first metal layer 1 of the inductor, the first metal layer of the inductor includes a plurality of discrete metal segments, and the formed structure is as follows figure 1 shown. Then deposit the first nitride layer on the first metal layer of the inductor, so that the first nitride covers each metal segment, such as figure 2 shown. The nitride of the present invention plays the role of insulation, such as silicon nitride and the like. Then deposit the inductor second metal layer 2 on the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com