Detection system and shifting device thereof

A technology of shifting device and measuring position, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of limited height space, difficulty in setting up shifting device, etc., and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

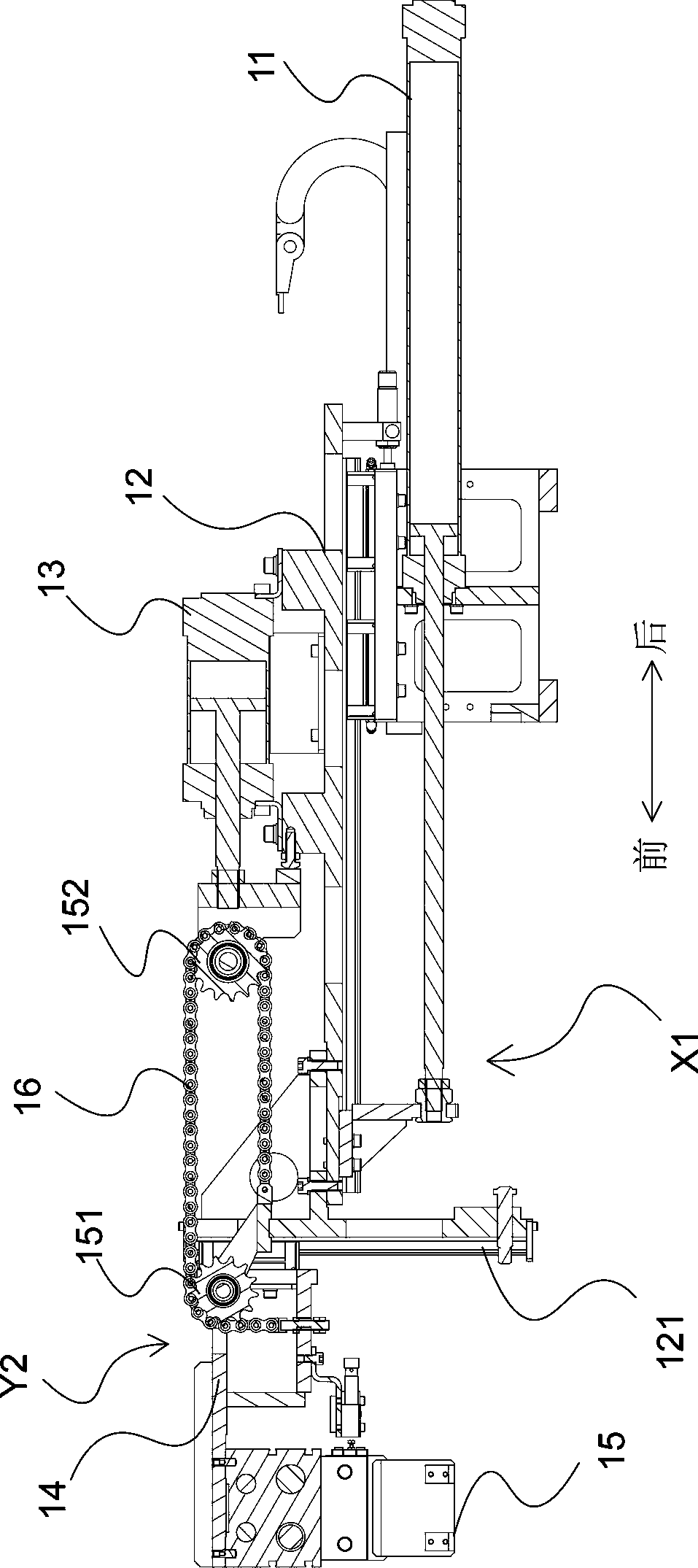

[0023] Terms such as "first" and "second" quoted in this application are for the purpose of expressing technical solutions, rather than limiting the protection scope of this application, and the above terms can be interchanged. The orientation terms such as "front", "rear", "horizontal" and "vertical" described below are described based on the relative orientation shown in the figure, and do not constitute a limitation to the present application.

[0024] The technical solutions of the present application will be described in detail below with reference to the accompanying drawings and in combination with implementation manners.

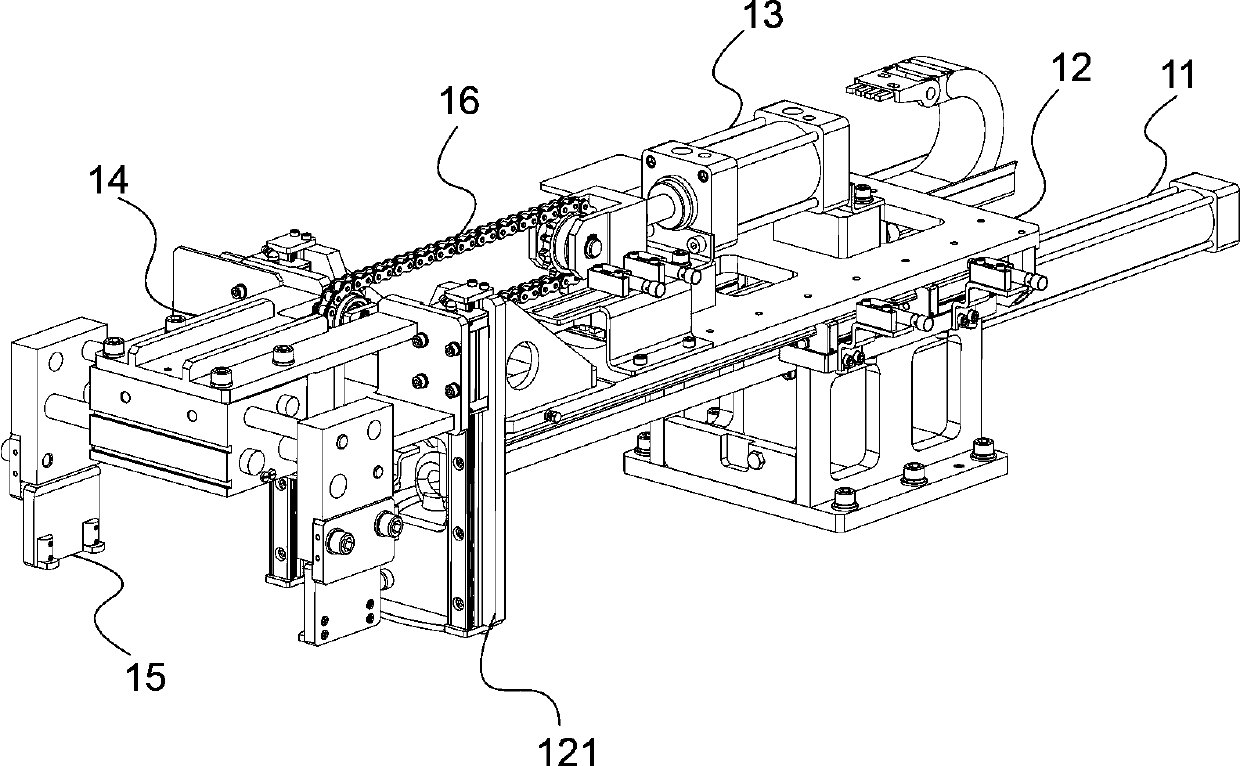

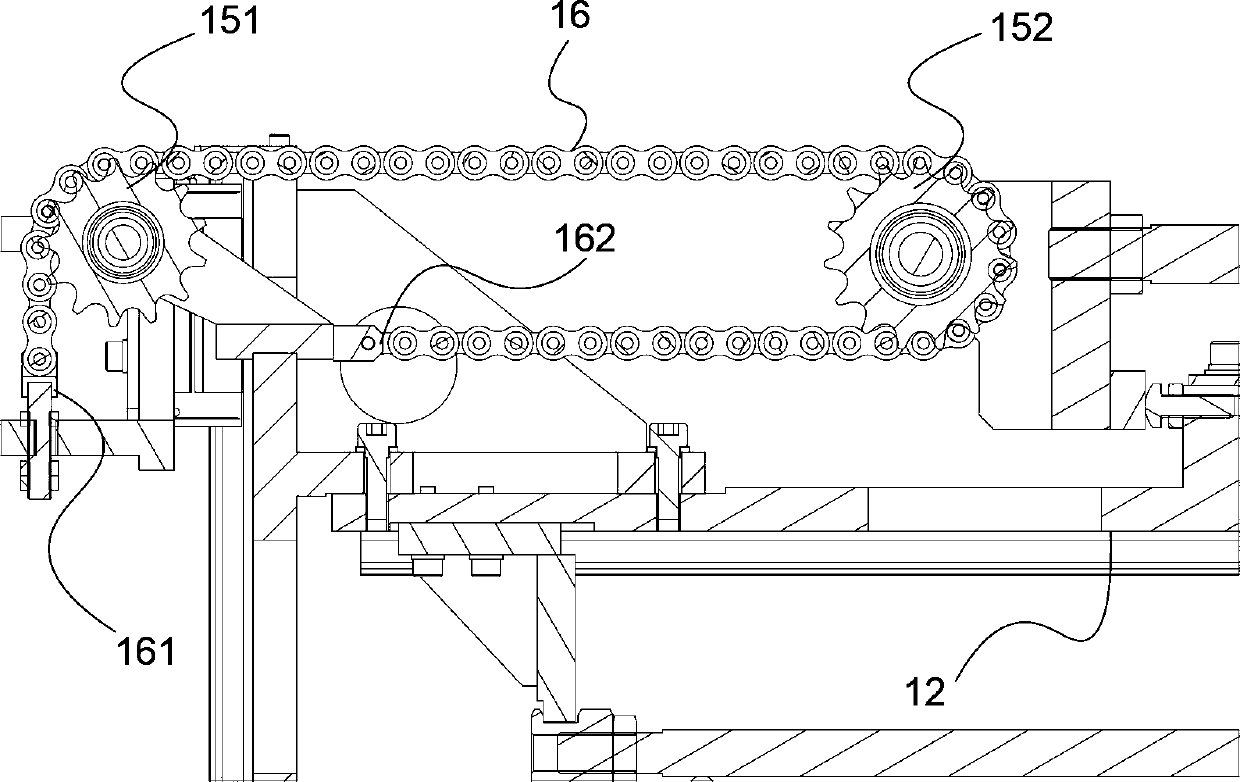

[0025] like figure 1 As shown, the present application provides a shifting device for the detection system, the shifting device includes: a first driver 11, the first driver 11 is fixedly installed on the frame; a horizontal sliding seat 12, the horizontal sliding seat 12 It can be horizontally slidably installed on the frame and connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com